Description

Product Overview

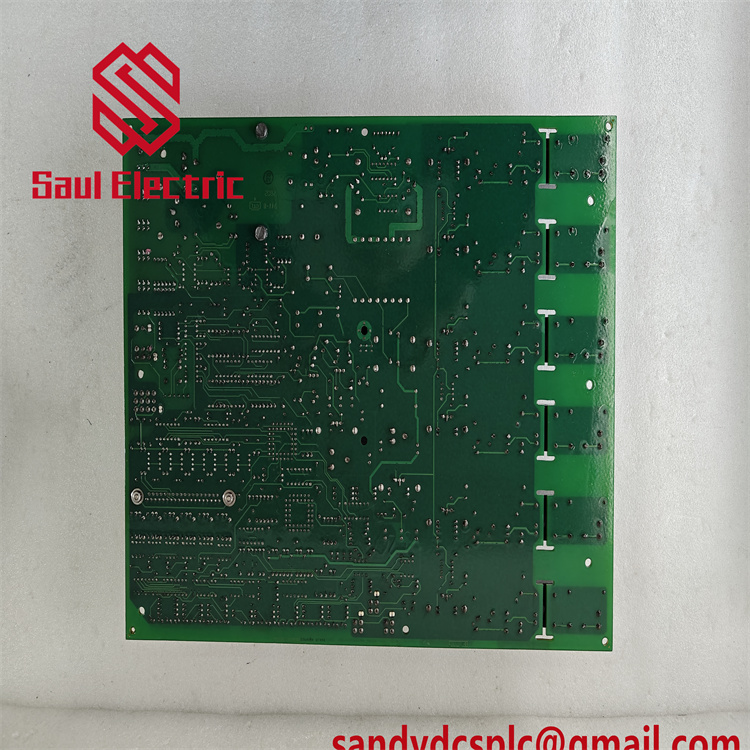

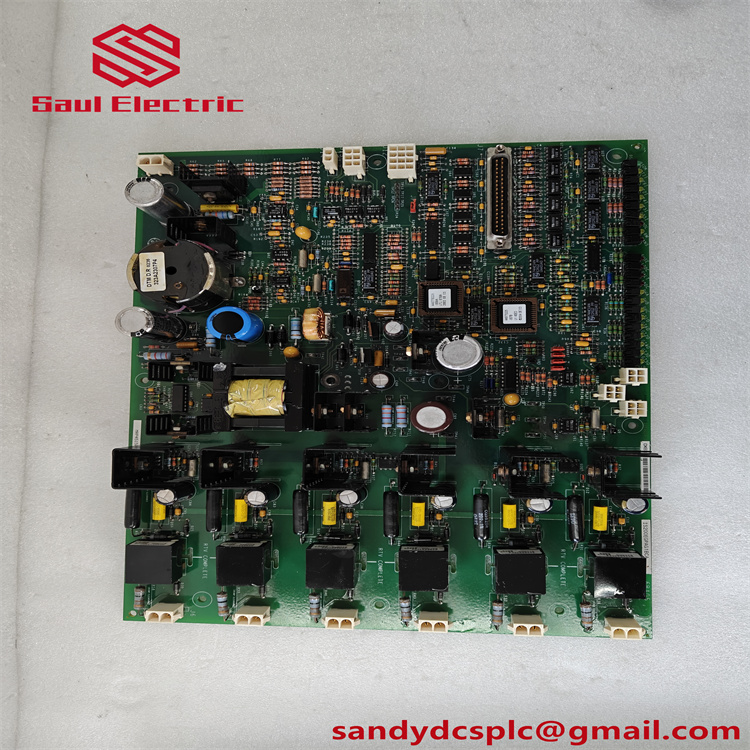

The GE IS220PSVOH1A REV E is a high-performance Servo Control I/O Pack within the GE Mark VIe distributed control system, designed for precision motion control in industrial automation. Serving as a critical interface between central controllers and servo drives, it translates complex control commands into precise electrical signals to drive servo motors with exceptional accuracy. This module integrates dual 10/100 Ethernet ports for flexible network connectivity and supports protocols like Modbus TCP and EtherNet/IP, enabling seamless integration into diverse automation architectures. Engineered for reliability in harsh environments, the IS220PSVOH1A REV E features robust EMI shielding, wide temperature tolerance (-20°C to +60°C), and IP20-rated protection. Its role in optimizing motion control—spanning position, speed, and torque regulation—makes it indispensable for applications demanding sub-millisecond response times and minimal operational downtime.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PSVOH1A REV E |

| Manufacturer | GE (General Electric) |

| Product Type | Servo Control I/O Module |

| Input Voltage | 28 V DC (from terminal board) |

| Ethernet Ports | Dual 10/100 RJ45 |

| Communication Protocols | Modbus TCP, EtherNet/IP |

| Operating Temperature | -20°C to +60°C |

| Protection Rating | IP20 |

| Control Accuracy | ±0.01% (position/speed) |

| Response Time | <1 ms |

| Mounting Compatibility | TSVOH1D/TSVCH1A terminal boards |

| Weight | 0.6 kg |

| Dimensions | 120 × 80 × 40 mm (W×H×D) |

Key Features and Advantages

Precision Motion Control

The IS220PSVOH1A REV E leverages GE’s advanced servo algorithms to achieve high-fidelity position and velocity control, critical for robotics and CNC machinery. Its direct torque control (DTC) capability eliminates reliance on external encoders, reducing system complexity and cost.

Robust Connectivity and Diagnostics

Dual Ethernet ports support redundant network configurations, enhancing fault tolerance. Integrated diagnostics monitor real-time parameters (e.g., motor temperature, current ripple) and log faults via LED indicators (PWR/ATTN, LINK/TxRx), enabling proactive maintenance and minimizing unplanned downtime.

Industrial Durability

Designed for demanding environments, the module’s hardened casing dissipates heat efficiently, while conformal-coated PCBs resist humidity and chemical corrosion. Compliance with IEC 61800-5 safety standards ensures operational integrity in critical sectors like energy and manufacturing.

Application Areas

The GE IS220PSVOH1A REV E excels in high-precision industrial automation:

- Robotics & Manufacturing: Synchronizes robotic arms in automotive assembly lines, ensuring millimeter-accurate positioning for welding and painting tasks.

- Energy Infrastructure: Controls turbine pitch systems in wind farms, dynamically adjusting blade angles to optimize power output under variable wind conditions.

- Process Industries: Manages high-speed packaging machinery (e.g., fillers, labelers) in pharmaceuticals, maintaining ±0.1 mm tolerance for product integrity.

- Heavy Machinery: Drives hydraulic actuators in steel rolling mills, delivering consistent torque for uniform material thickness.

Related Products

- IS220PSVOH1B: Enhanced revision with extended temperature range (-30°C to +70°C) for extreme environments.

- TSVOH1D Terminal Board: Direct-mount interface for IS220PSVOH1A, simplifying cabling and signal integrity.

- IC693PWR711: Redundant power supply module for Mark VIe systems, ensuring backup during grid fluctuations.

- DS200SDCCG1AGD: Servo drive compatible with IS220PSVOH1A, supporting 200A peak current for heavy loads.

- IS215ACLEH1A: Communication gateway for integrating legacy GE systems with Mark VIe networks.

Installation and Maintenance

Installation Preparation: Mount the IS220PSVOH1A REV E vertically on TSVOH1D terminal boards using DIN-rail clips. Ensure 28V DC power input (≤±5% tolerance) and ground resistance <0.1Ω. Route Ethernet cables away from high-voltage lines (>20 cm separation) to prevent EMI interference.

Maintenance Recommendations: Clean air vents quarterly using dry compressed air (≤0.3 MPa). Calibrate servo offsets annually via DriveWorksEZ software. Replace electrolytic capacitors after 50,000 operational hours to prevent aging-related failures.

Product Assurance

GE provides a 12-month global warranty covering defects in materials and workmanship. Technical support includes 24/7 remote diagnostics and on-site service within 72 hours for critical failures. All modules undergo 168-hour burn-in testing and comply with ISO 9001/14001 standards.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com