Description

Product Overview

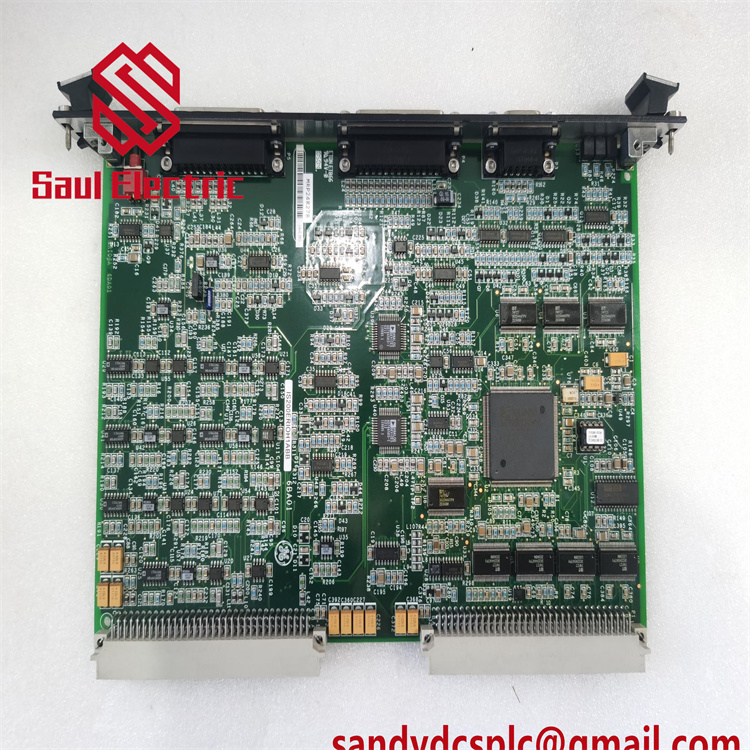

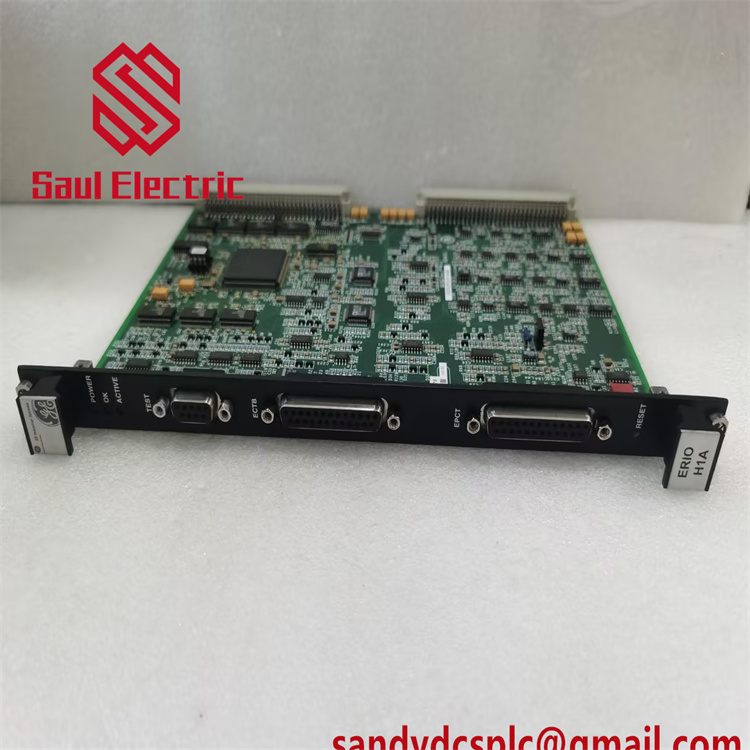

The GE IS220PRTDHIA.REV E is a high-precision RTD Input Module engineered for GE’s Mark VIe turbine control system, a cornerstone of industrial automation in power generation, oil & gas, and heavy machinery. As an upgraded revision of its predecessor (REV D), this module specializes in accurate temperature monitoring by interfacing with Platinum Resistance Temperature Detectors (RTDs), delivering real-time data for critical applications such as turbine health management, process control, and predictive maintenance.

The GE IS220PRTDHIA.REV E is a high-precision RTD Input Module engineered for GE’s Mark VIe turbine control system, a cornerstone of industrial automation in power generation, oil & gas, and heavy machinery. As an upgraded revision of its predecessor (REV D), this module specializes in accurate temperature monitoring by interfacing with Platinum Resistance Temperature Detectors (RTDs), delivering real-time data for critical applications such as turbine health management, process control, and predictive maintenance.

Featuring 8 isolated channels supporting 2/3/4-wire RTDs (PT100, PT500, Ni100), the IS220PRTDHIA.REV E offers enhanced 16-bit resolution (up from 15-bit in REV D) for precise temperature measurement across -200°C to +850°C. Its advanced signal conditioning minimizes noise and drift, while software-configurable filters (0.1/1/10Hz) adapt to high-vibration environments—essential for monitoring turbine inlet temperatures or reactor walls. The module’s conformal-coated PCB and -30°C to +65°C operating range ensure durability in harsh settings, from desert solar farms to arctic refineries.

Integrating seamlessly with Mark VIe backplanes, the IS220PRTDHIA.REV E supports dual Ethernet ports for redundant communication and Modbus protocols for fast data transfer. Upgraded diagnostics, including real-time lead resistance compensation and open-circuit detection, simplify troubleshooting, while compatibility with GE’s Control System Toolbox enables remote configuration. This combination of precision, reliability, and flexibility solidifies the IS220PRTDHIA.REV E as a critical component for temperature-sensitive industrial processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PRTDHIA.REV E |

| Manufacturer | General Electric (GE) |

| Product Type | RTD Input Module |

| Series | Mark VIe |

| Number of Channels | 8 (fully isolated) |

| Supported RTD Types | PT100, PT500, Ni100 (2/3/4-wire configurable) |

| Temperature Range | -200°C to +850°C |

| Resolution | 16-bit (up from 15-bit in REV D) |

| Power Supply | 24V DC (redundant support) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 15.2 cm x 10.2 cm x 5.1 cm (6.0″ x 4.0″ x 2.0″) |

| Weight | ~0.5 kg |

| Certifications | UL 508, CE, CSA, ATEX |

Main Features and Advantages

Enhanced measurement precision: The IS220PRTDHIA.REV E upgrades to 16-bit resolution, reducing temperature measurement error to ±0.1°C—critical for monitoring turbine exhaust temperatures or chemical reactor walls where small deviations can impact efficiency or safety.

Enhanced measurement precision: The IS220PRTDHIA.REV E upgrades to 16-bit resolution, reducing temperature measurement error to ±0.1°C—critical for monitoring turbine exhaust temperatures or chemical reactor walls where small deviations can impact efficiency or safety.

Advanced signal conditioning: Integrated lead resistance compensation (up to 100Ω) eliminates errors from long cable runs, a common challenge in large facilities like refineries or power plants. Software-configurable filters (0.1/1/10Hz) further reduce noise in high-vibration environments.

Intelligent diagnostics: Real-time alerts for open circuits, short circuits, and sensor drift enable proactive maintenance. LED indicators (Power, Channel Status, Fault) provide at-a-glance system health, reducing troubleshooting time by up to 30% compared to REV D.

Hazardous environment readiness: ATEX certification expands applicability to Zone 2 hazardous areas, making the IS220PRTDHIA.REV E suitable for oil & gas extraction, chemical processing, and other safety-critical industries.

Backward compatibility: Seamlessly integrates with legacy Mark VIe components (e.g., IS200JPDSG1ACB power modules) and GE’s Control System Toolbox, simplifying retrofits of older systems without full overhauls.

Application Areas

The GE IS220PRTDHIA.REV E excels in temperature-critical industrial environments:

The GE IS220PRTDHIA.REV E excels in temperature-critical industrial environments:

- Power Generation: Monitors turbine inlet/outlet temperatures, generator winding heat, and boiler tube temperatures, ensuring compliance with efficiency standards and preventing overheating.

- Oil & Gas: Tracks reactor temperatures in refineries, compressor intercooler performance, and wellhead fluid heat—critical for optimizing extraction and refining processes.

- Chemical Processing: Controls batch reactor temperatures with precision, ensuring product quality and safety in pharmaceutical or specialty chemical production.

- Manufacturing: Monitors furnace temperatures in steel mills, plastic extrusion lines, and glass production, maintaining consistent product quality.

- Renewable Energy: Regulates heat in solar thermal plants and wind turbine gearboxes, maximizing energy output while protecting equipment from thermal stress.

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation preparation: Ensure the Mark VIe backplane is powered off and grounded. Verify RTD compatibility (2/3/4-wire) and use shielded twisted-pair cables to minimize noise. Configure via GE’s Control System Toolbox (v10.0+), setting filter rates and temperature ranges for specific applications. Mount the IS220PRTDHIA.REV E in a dust-free, vibration-damped enclosure to preserve accuracy.

Installation preparation: Ensure the Mark VIe backplane is powered off and grounded. Verify RTD compatibility (2/3/4-wire) and use shielded twisted-pair cables to minimize noise. Configure via GE’s Control System Toolbox (v10.0+), setting filter rates and temperature ranges for specific applications. Mount the IS220PRTDHIA.REV E in a dust-free, vibration-damped enclosure to preserve accuracy.

Maintenance recommendations: Inspect quarterly for loose connections and dust accumulation. Calibrate annually using GE’s certified standards to maintain ±0.1°C precision. Monitor LED indicators for fault alerts, and update firmware via the Control System Toolbox to access new diagnostic features. Replace sensors if drift exceeds 0.5°C to ensure reliable temperature data.

Product Warranty

GE provides a 1-year warranty for the IS220PRTDHIA.REV E, covering defects in materials and workmanship. This includes free replacement/repair and 24/7 technical support via phone, email, or GE’s online portal. Extended warranties (up to 5 years) and on-site calibration services are available for mission-critical applications. GE’s global network of certified technicians ensures rapid support, reinforcing confidence in the IS220PRTDHIA.REV E’s performance in demanding environments.

GE provides a 1-year warranty for the IS220PRTDHIA.REV E, covering defects in materials and workmanship. This includes free replacement/repair and 24/7 technical support via phone, email, or GE’s online portal. Extended warranties (up to 5 years) and on-site calibration services are available for mission-critical applications. GE’s global network of certified technicians ensures rapid support, reinforcing confidence in the IS220PRTDHIA.REV E’s performance in demanding environments.

HS:8471800000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com