Description

Product Overview

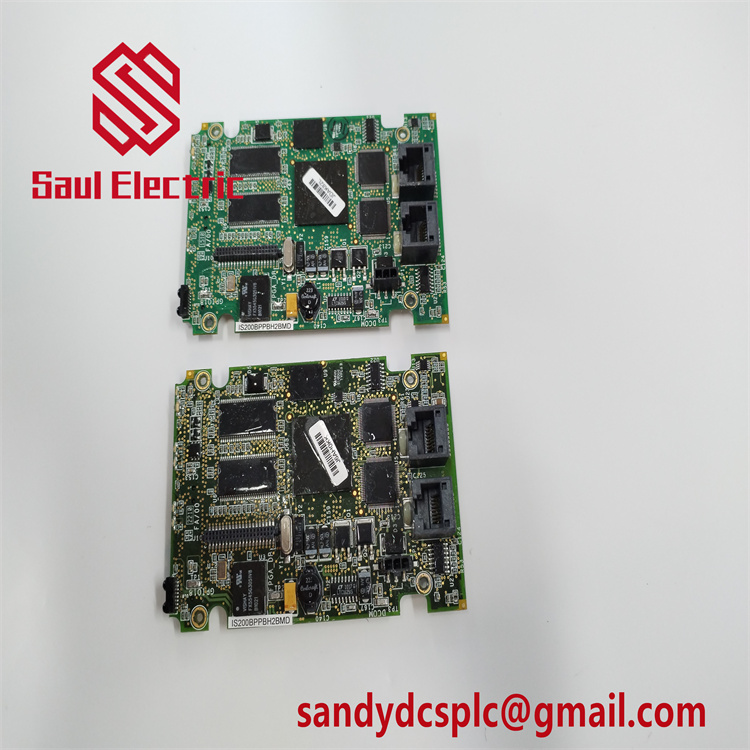

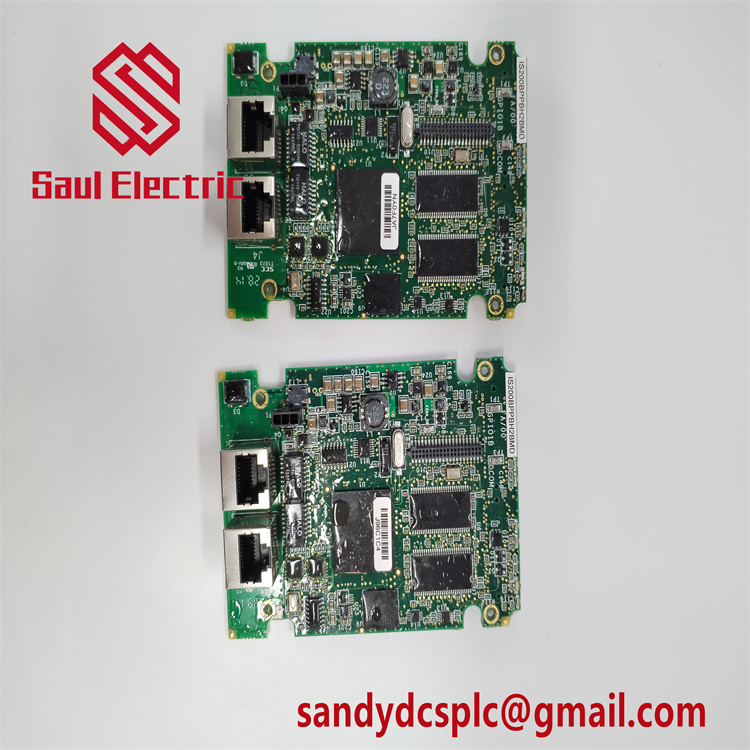

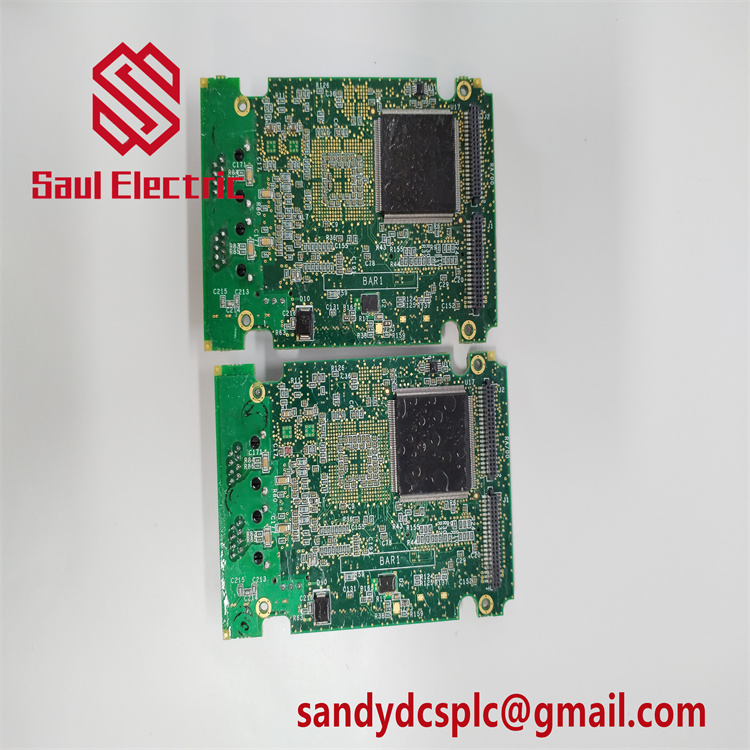

The GE IS220PRTDH1A REV H is a specialized Resistance Temperature Detector (RTD) Input Module designed for GE’s Mark VIe Speedtronic turbine control systems. This high-precision module excels in converting RTD sensor signals into accurate temperature readings, critical for real-time monitoring and control in industrial environments like power plants, oil refineries, and chemical processing facilities. Engineered with 8 input channels, the GE IS220PRTDH1A REV H supports simultaneous multi-point temperature monitoring (e.g., Pt100 sensors), ensuring operational stability and preventing equipment failure in gas/steam turbines. Its robust construction features 1,500V AC isolation and conformal-coated PCBs, enabling reliable performance in extreme conditions (-40°C to +70°C) and hazardous areas (Class I, Div. 2 certified with compatible terminal boards). Integrated dual Ethernet ports (10/100 Mbps) facilitate seamless data exchange via Modbus TCP/EtherNet/IP, while a local processor enables real-time diagnostics and rapid response to thermal anomalies, solidifying its role in safety-critical automation architectures.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PRTDH1A REV H |

| Manufacturer | General Electric (GE) |

| Product Type | RTD Input Module |

| Input Channels | 8 (supports Pt100 RTDs) |

| Input Signal Range | Resistance: 0–400 Ω (Pt100) |

| Accuracy | ±0.1% Full Scale (FS) |

| Isolation Voltage | 1,500V AC (channel-to-system) |

| Operating Temperature | -40°C to +70°C (extended range) |

| Communication | Dual RJ45 Ethernet (Modbus TCP/EtherNet/IP) |

| Dimensions (L×W×H) | 120 × 80 × 40 mm (approx.) |

| Weight | 0.38 kg |

| Hazardous Certification | Class I, Div. 2 (with terminal boards like IS200TRTDH2D) |

Key Features and Advantages

1. High-Precision Temperature Monitoring

The GE IS220PRTDH1A REV H achieves ±0.1% FS accuracy through 16-bit ADC conversion and hardware linearization, critical for detecting minute temperature drifts in turbine bearings or reactor vessels. Its 8-channel design allows centralized monitoring, reducing wiring complexity by 60% compared to discrete modules.

2. Industrial Durability & Safety Compliance

Featuring extended temperature tolerance (-40°C to +70°C) and IP20-rated enclosure, the module withstands vibration (5G RMS), humidity, and chemical exposure. When paired with IS200TRTDH2D terminal boards, it meets ATEX/IECEx Zone 2 standards for explosive atmospheres.

3. Seamless Integration & Diagnostics

Dual Ethernet ports enable redundant communication paths for fail-safe operations. Integrated diagnostics via GE’s ToolboxST software provide real-time alerts for sensor faults (e.g., open-circuit RTDs), slashing troubleshooting time by 50%. Hot-swappable design permits module replacement without turbine shutdown.

Application Areas

- Power Generation: Monitors exhaust gas temperatures in gas turbines and steam chests in coal-fired plants, triggering safety shutdowns if thresholds exceed 700°C.

- Oil & Gas: Tracks pipeline temperatures in compressor stations, preventing wax formation in Arctic operations (-40°C environments).

- Chemical Processing: Controls reactor jacket temperatures during exothermic reactions, ensuring ±1°C stability for catalyst efficiency.

- Marine Propulsion: Monors thrust bearing temperatures in ship engines, certified for salt fog resilience per DNV-GL standards.

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation: Mount vertically on DIN rail using IS200TRTDH2D terminal board. Ensure shielded twisted-pair cabling (AWG 18–22) with ≥20 cm separation from high-voltage sources to minimize EMI. Verify ground resistance ≤0.1Ω.

Maintenance: Perform annual calibration with Fluke 754 calibrator. Replace electrolytic capacitors after 50,000 operational hours (≈5.7 years). For firmware updates, use ToolboxST v11.1+ with network redundancy enabled.

Product Assurance

GE provides a 12-month global warranty covering material and workmanship defects. Critical failure support includes 24/7 remote diagnostics via GE Digital Support Hub and 48-hour on-site response for SIL 2-certified systems. Modules undergo 168-hour burn-in testing per IEC 61131-2, with MTBF exceeding 200,000 hours.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com