Description

Product Overview

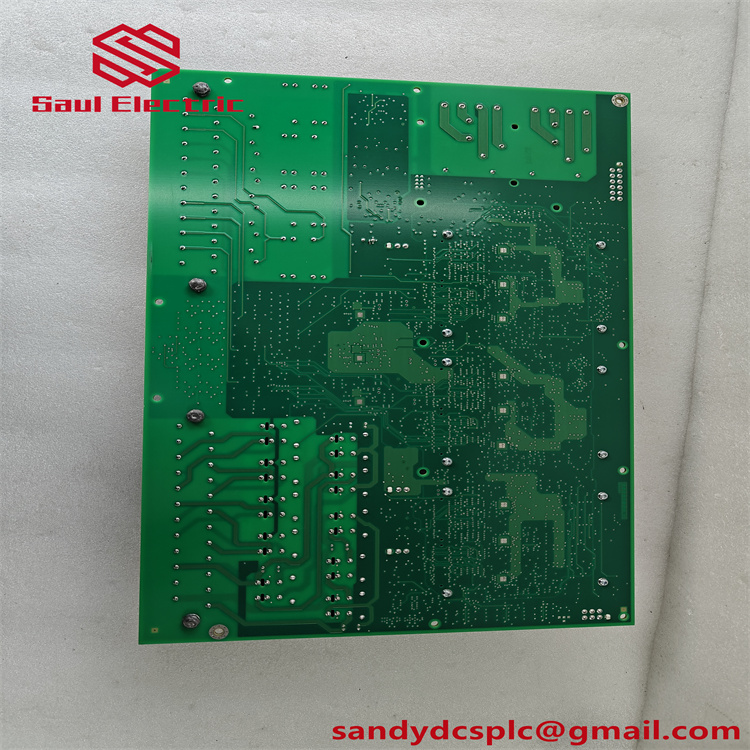

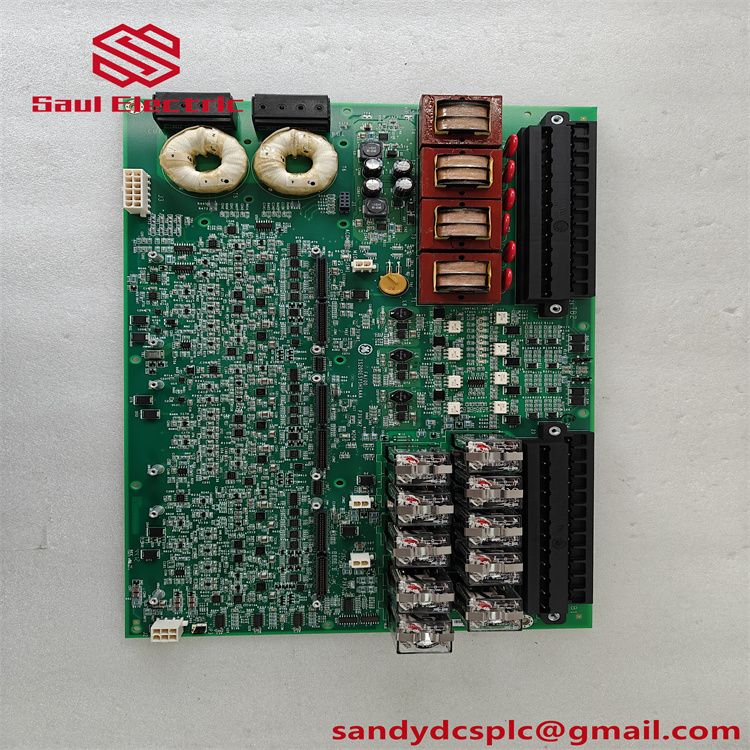

The GE IS220PPROH1A REV E is a high-reliability Profibus-DP communication module designed for GE’s Mark VIe industrial control systems. As a critical interface between controllers and field devices, it enables deterministic data exchange in real-time automation networks. This module integrates dual Profibus ports (master/slave configurable) with galvanic isolation, supporting baud rates up to 12 Mbps and connecting up to 124 nodes per segment. Engineered for mission-critical environments like power generation and oil refineries, the IS220PPROH1A REV E features redundant power inputs and complies with IEC 61158-2 standards for electromagnetic immunity. Its plug-and-play architecture simplifies integration with existing Mark VIe racks, reducing commissioning time while ensuring seamless interoperability with Siemens, ABB, and other Profibus-compatible devices.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PPROH1A REV E |

| Manufacturer | GE (General Electric) |

| Product Type | Profibus-DP Communication Module |

| Protocol Compliance | Profibus-DP V1 (EN 50170) |

| Data Transfer Rate | 9.6 kbps to 12 Mbps (auto-negotiating) |

| Isolation Voltage | 1500 V DC (port-to-system) |

| Connectors | 2 × Sub-D 9-pin (RS-485) |

| Power Input | 24–28V DC (dual redundant terminals) |

| Operating Temperature | -40°C to +70°C |

| Housing Protection | IP20 (requires panel mounting) |

| Diagnostics | LED status (PWR, COM, ERR) |

| Dimensions | 110 × 100 × 35 mm |

| Weight | 0.45 kg |

| Mean Time Between Failures | >250,000 hours |

Key Features and Advantages

1. Deterministic Performance

Achieves sub-1ms cycle times for time-critical applications like turbine control. Hardware-based token passing eliminates CPU loading issues during network congestion.

2. Robust Connectivity

Dual ports support daisy-chaining without repeaters (max. 1,200m per segment). Built-in surge protection (±30 kV) and 1500V galvanic isolation prevent ground loops in noisy plants.

3. Advanced Diagnostics

Real-time monitoring of node health (station address, signal quality) through Mark VIe’s ToolboxST software. Preemptive alerts for cable breaks or node failures minimize downtime.

4. Safety-Certified Design

SIL 2-certified (IEC 61508) architecture includes watchdog timers and redundant clocks for fail-safe operation in hydrocarbon processing environments.

Application Areas

- Energy Generation: Synchronizes gas turbine auxiliaries (fuel valves, igniters) via Profibus-DP across combined-cycle plants.

- Chemical Processing: Integrates distributed I/O for reactor temperature/pressure control in SIL 2-rated safety instrumented systems.

- Water Treatment: Manages pump stations and valve actuators across remote sites using fiber-optic Profibus extenders.

- Manufacturing: Enables high-speed communication between Mark VIe controllers and robotic cells in automotive assembly.

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation Preparation:

Mount on TSVOH1D terminal board using DIN rail clip. Ensure shielded Profibus cables (AWG 22) with 360° termination at both ends. Maintain 20 cm separation from AC power lines.

Maintenance Recommendations:

Quarterly diagnostics via ToolboxST to check signal distortion levels. Replace communication capacitors every 8 years. Firmware updates require temporary network shutdown.

Product Assurance

GE warrants IS220PPROH1A REV E against defects for 18 months from delivery. Global support includes 24/7 phone diagnostics and 48-hour on-site response for critical sites. Complies with ATEX Zone 2 and IECEx certification for hazardous areas.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com