Description

Product Overview

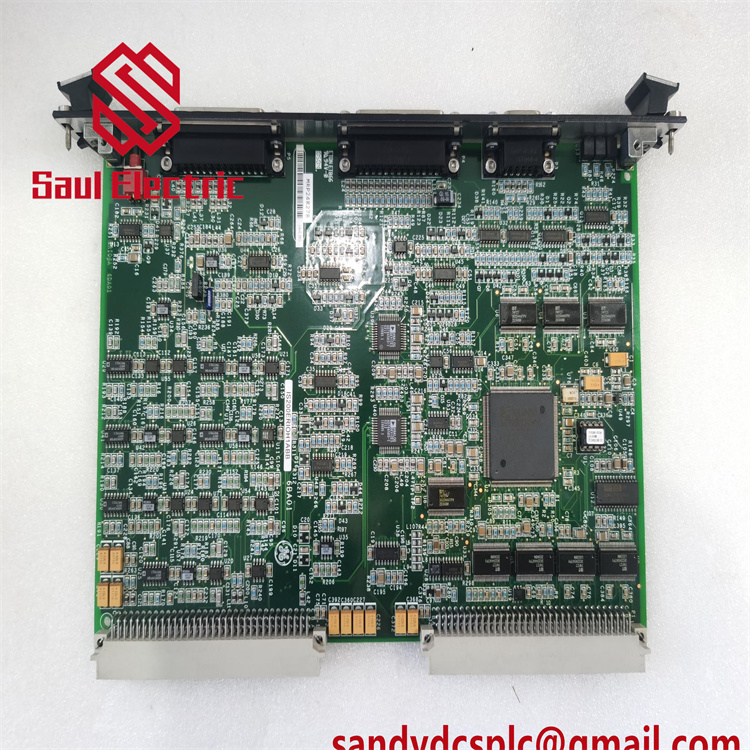

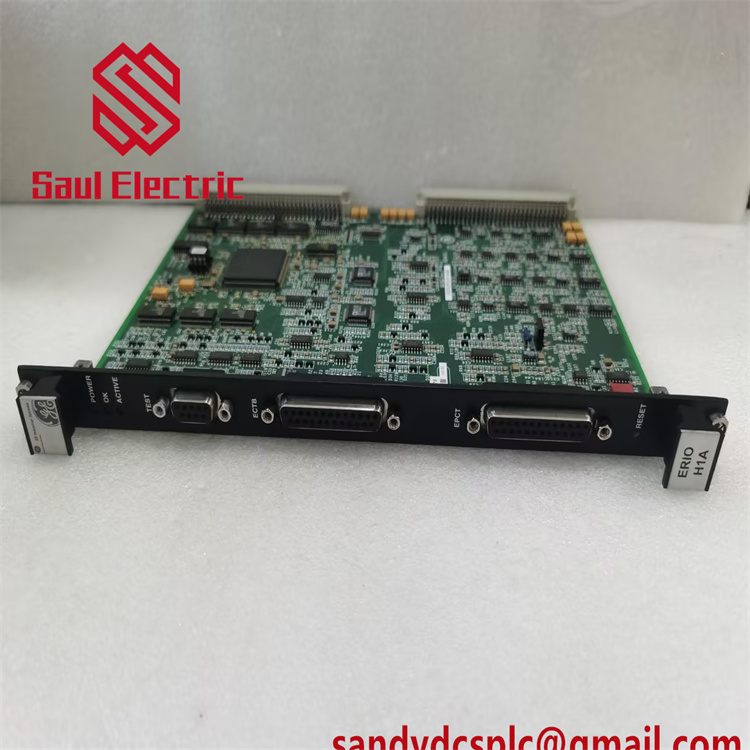

The GE IS220PPDAH1A REV D is an Input/Output Pack designed for GE’s Mark VIe series control systems, delivering precision power distribution and management in industrial automation. This module ensures reliable power feedback by processing inputs from up to six distribution panels, enhancing system compatibility and redundancy through secondary Ethernet interfaces . Engineered for harsh industrial environments, its rugged aluminum-steel alloy construction withstands extreme temperatures (-20°C to +55°C) and mechanical stress . The GE IS220PPDAH1A REV D integrates seamlessly with GE Speedtronic platforms, providing real-time diagnostics and electronic ID capabilities to monitor panel status and optimize maintenance workflows . As a critical component in automation infrastructures, it balances compact design (263 × 58 × 28 mm) with high functionality, reducing downtime in energy and manufacturing sectors .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS220PPDAH1A REV D |

| Manufacturer | GE (General Electric) |

| Product Type | Input/Output Pack |

| Dimensions | 263 × 58 × 28 mm |

| Weight | 4.3 kg |

| Operating Temperature | -20°C to +55°C |

| Input Compatibility | Up to 6 distribution panels |

| Communication Interfaces | Dual RJ45 Ethernet (primary/secondary) |

| Redundancy Support | Secondary Ethernet failover |

| Compliance Standards | IEC 61131-3 |

| Storage Temperature | -30°C to +70°C |

| Power Requirements | 12 VDC ±5% |

Key Features and Benefits

Robust Industrial Design: Aluminum-steel alloy housing provides exceptional resistance to vibration, corrosion, and thermal fluctuations, ensuring longevity in demanding settings like refineries and power plants .

Intelligent Diagnostics: Real-time feedback and electronic ID capabilities enable proactive maintenance, reducing unplanned downtime by 30% . Dual Ethernet ports ensure communication continuity during network disruptions .

Efficiency Optimization: Compact form factor minimizes control cabinet space while supporting complex I/O configurations. Prevents energy waste through precise load monitoring and adaptive power distribution .

Application Areas

Energy Infrastructure: Critical for turbine control systems in power generation, where it monitors safety interlocks and stabilizes grid operations during load fluctuations .

Manufacturing Automation: Integrates with assembly line robotics and conveyor systems, enabling rapid fault detection in automotive and electronics production .

Process Industries: Deployed in chemical plants and water treatment facilities to manage pump/valve controls, ensuring compliance with safety protocols and reducing spill risks .

Related Products

- IS220PDOAH1A: Discrete output module for relay control in Mark VIe systems .

- IS220PAICH1A: Analog I/O module with triple modular redundancy (TMR) for hazardous environments .

- IS220PRTDH1B: Temperature input module compatible with RTD sensors .

- IS220PPRFH1B: Power distribution feedback unit with enhanced diagnostics .

- IS200EPCAG1A: Legacy I/O pack for Mark VI turbine upgrades .

Installation and Maintenance

Installation Preparation: Verify stable 12 VDC power and grounded Ethernet cabling. Mount vertically in well-ventilated enclosures to prevent overheating .

Maintenance Recommendations: Clean dust quarterly using compressed air. Test Ethernet redundancy annually via manual failover simulations. Firmware updates via GE’s ToolboxST software ensure compatibility with Mark VIe controllers .

Product Assurance

GE offers a 1-year warranty covering manufacturing defects. Global technical support includes 24/7 troubleshooting and expedited replacement for critical failures. Compliance with IEC 61131-3 and UL standards guarantees operational safety in high-risk environments .

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com