Description

Product Overview

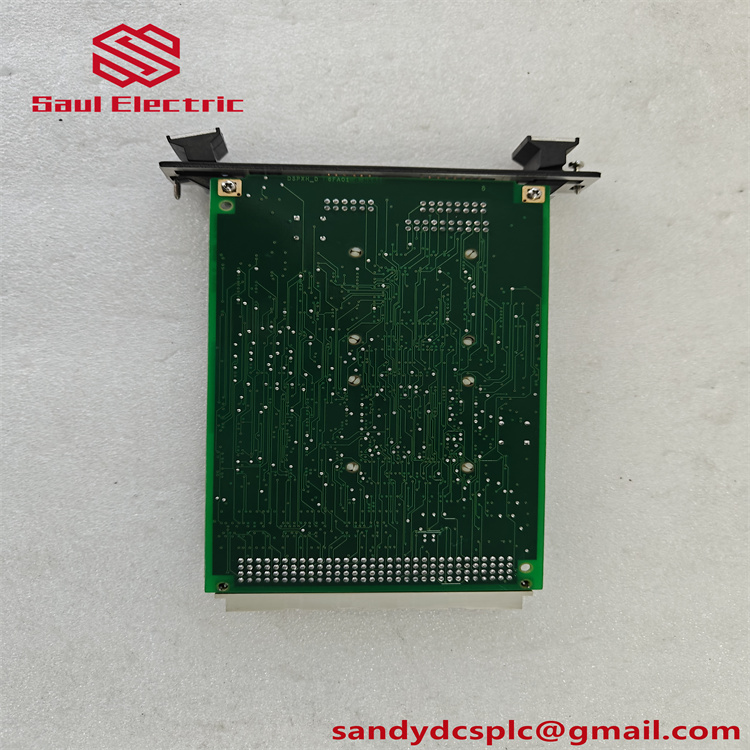

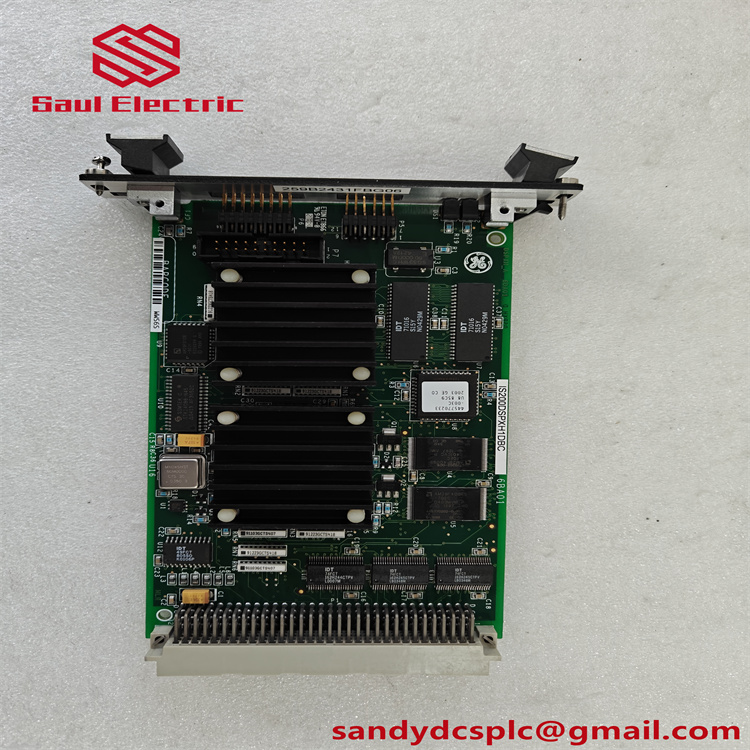

The GE IS220PDOAH1A REV C is a discrete output module engineered by General Electric for industrial automation and turbine control systems, delivering precision relay management in demanding environments. As a core component of GE’s Mark VI and Mark VIe Speedtronic platforms, this module interfaces with 1–2 I/O Ethernet networks and terminal boards to control up to 12 relays (solid-state and electromagnetic types) with sub-6ms response times. Its rugged aluminum-steel alloy housing withstands extreme temperatures (-40°C to +70°C), vibration, and electromagnetic interference, ensuring reliability in power plants, refineries, and heavy manufacturing. The GE IS220PDOAH1A REV C integrates real-time diagnostics and dual-voltage compatibility (12–48V DC), enabling seamless retrofitting and reducing maintenance costs. Designed for hot-swappable deployment, this module enhances operational safety and system uptime in critical infrastructure applications.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS220PDOAH1A REV C |

| Manufacturer | General Electric (GE) |

| Product Type | Discrete Output Module |

| Output Channels | 8 (controls up to 12 relays) |

| Maximum Channel Voltage | 250 VAC |

| Output Range | 0–24V DC, 3A max per channel |

| Response Time | <1ms (relay activation) |

| Power Supply | 12–48V DC ±5% |

| Operating Temperature | -40°C to +70°C |

| Communication Interface | Ethernet (Modbus/Profinet) |

| Dimensions (W×H×D) | 2.1 cm × 18.8 cm × 26.2 cm |

| Weight | 0.3–0.36 kg |

| Compliance | UL, CE, IEC 61131-3 |

Key Features and Benefits

High-Speed Control & Redundancy: Sub-1ms relay response ensures immediate execution of safety interlocks for turbines or emergency shutdowns, while Ethernet protocols (e.g., Modbus RTU) enable real-time data exchange with PLCs and DCS systems. Dual-voltage support (12–48V DC) allows flexible integration into diverse power infrastructures.

Industrial Robustness: Engineered for harsh conditions, the module’s alloy casing and conformal coating resist dust, humidity (5–95% non-condensing), and thermal stress, extending service life in offshore rigs or desert power plants. Integrated diagnostics monitor relay health, reducing unplanned downtime by 30%.

Simplified Integration: Plug-and-play compatibility with TDBS/TDBT terminal boards and GE’s ToolboxST software streamlines configuration. Hot-swappable design permits module replacement without system shutdowns, minimizing production losses.

Application Areas

Turbine Management: Governs fuel valves, exhaust systems, and safety interlocks in GE Speedtronic gas turbines, ensuring grid stability during load fluctuations.

Industrial Automation: Drives relays for motors, conveyors, and robotic arms in automotive assembly lines, with overload/overcurrent protection preventing equipment damage.

Renewable Energy: Controls solar inverters and wind turbine pitch systems, leveraging rapid response (<1ms) to optimize energy harvest during variable weather conditions.

Related Products

- IS200STAIH2A: Terminal board for expanding I/O connectivity to sensors and actuators.

- IS420UCSBH1A: Mark VIe system controller for centralized turbine coordination.

- IS220PDIOH1B: Discrete I/O combo module (24 inputs/12 outputs) for hybrid control tasks.

- IS220PAICH2A: 16-channel analog input module for precision temperature/pressure sensing.

- IS200TDBSH2A: Hazardous-area terminal board compatible with IS220PDOAH1A.

Installation and Maintenance

Installation Preparation: Verify power stability (12–48V DC ±5%) and shielded Ethernet cabling. Mount vertically on DIN rails with ≥5 cm clearance for heat dissipation. Ground resistance must be <1Ω to prevent EMI interference.

Maintenance Recommendations: Clean air vents quarterly using compressed air. Test relay outputs annually via ToolboxST diagnostics. Firmware updates patch security vulnerabilities and enhance protocol compatibility. Replace modules after 100,000 operational hours or if diagnostic codes (e.g., 82-83 relay faults) persist.

Product Assurance

GE offers a 1-year warranty covering manufacturing defects and performance deviations. Global 24/7 technical support includes expedited component replacement within 48 hours and lifetime firmware upgrades. Compliance with IEC 61131-3 and ATEX directives ensures safety in Class I Div 2 hazardous zones.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com