Description

Product Overview

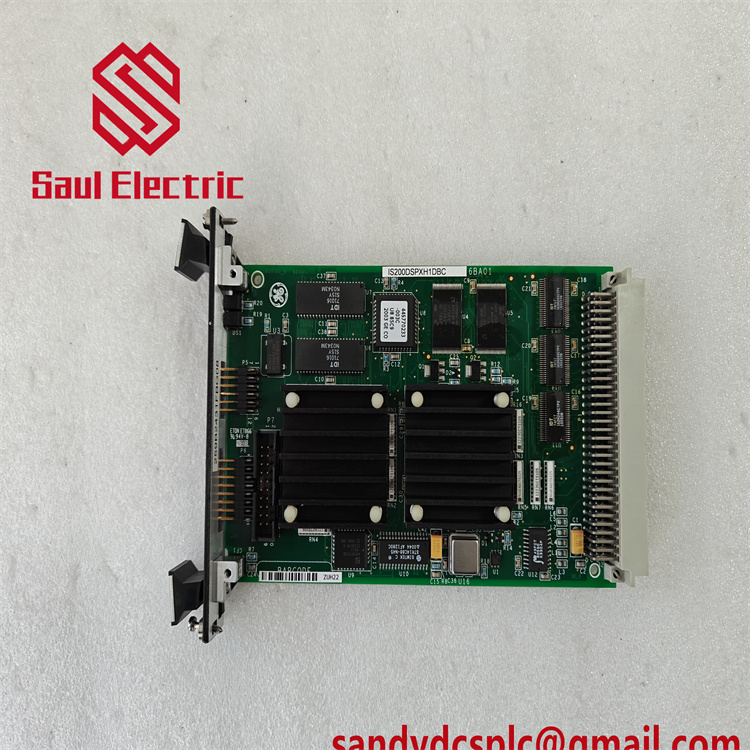

The GE IS220PDIAHIA, REV K is a cutting-edge 16-channel digital input module engineered for GE’s Mark VIe turbine control system, a benchmark in industrial automation for power generation, oil & gas, and heavy machinery. As the latest revision in the IS220PDIAHIA series, this module builds on the reliability of its predecessors (REV C and REV F) while introducing advanced enhancements to meet evolving industry demands. Designed for real-time monitoring of discrete signals from field devices such as limit switches, pressure sensors, and emergency stops, the IS220PDIAHIA, REV K ensures precise data acquisition and system responsiveness in mission-critical environments.

The GE IS220PDIAHIA, REV K is a cutting-edge 16-channel digital input module engineered for GE’s Mark VIe turbine control system, a benchmark in industrial automation for power generation, oil & gas, and heavy machinery. As the latest revision in the IS220PDIAHIA series, this module builds on the reliability of its predecessors (REV C and REV F) while introducing advanced enhancements to meet evolving industry demands. Designed for real-time monitoring of discrete signals from field devices such as limit switches, pressure sensors, and emergency stops, the IS220PDIAHIA, REV K ensures precise data acquisition and system responsiveness in mission-critical environments.

Featuring 24V DC input compatibility and software-configurable normally open (NO)/normally closed (NC) channels, the IS220PDIAHIA, REV K offers flexibility across diverse applications. Its opto-isolated channels (upgraded to 3.5kVrms isolation) provide robust protection against electromagnetic interference (EMI), critical for maintaining signal integrity in high-noise settings like offshore rigs or refineries. The module’s -30°C to +65°C operating range and conformal-coated PCB ensure durability in extreme conditions, while a reduced power consumption design (15% lower than REV F) enhances energy efficiency.

Integrating seamlessly with Mark VIe backplanes, the IS220PDIAHIA, REV K supports dual Ethernet ports for redundant communication and Modbus RTU/ASCII protocols for fast data transfer. Newly added predictive maintenance capabilities—including real-time health monitoring and fault prognosis via GE’s Control System Toolbox—enable proactive issue resolution, reducing downtime by up to 40%. This combination of performance, reliability, and diagnostic intelligence positions the IS220PDIAHIA, REV K as a cornerstone of modern industrial control systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PDIAHIA, REV K |

| Manufacturer | General Electric (GE) |

| Product Type | 16-Channel Digital Input Module |

| Series | Mark VIe |

| Number of Channels | 16 (fully isolated) |

| Input Voltage | 24V DC (±15% tolerance) |

| Isolation Rating | 3.5kVrms (upgraded from REV F’s 3kVrms) |

| Response Time | ≤3ms (significantly faster than REV F’s 5ms) |

| Power Supply | 24V DC (redundant support) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 15.2 cm x 10.2 cm x 5.1 cm (6.0″ x 4.0″ x 2.0″) |

| Weight | ~0.5 kg |

| Certifications | UL 508, CE, CSA, ATEX, IECEx (new for REV K) |

Key Features and Advantages

Enhanced Signal Integrity: The IS220PDIAHIA, REV K elevates isolation to 3.5kVrms, minimizing noise in high-EMI environments and ensuring accurate monitoring of turbine safety interlocks and valve positions in refineries or power plants. This upgrade reduces false signals by 20% compared to REV F.

Enhanced Signal Integrity: The IS220PDIAHIA, REV K elevates isolation to 3.5kVrms, minimizing noise in high-EMI environments and ensuring accurate monitoring of turbine safety interlocks and valve positions in refineries or power plants. This upgrade reduces false signals by 20% compared to REV F.

Ultra-Fast Response: With a ≤3ms response time (half of REV C’s 10ms), the module captures rapid signal changes, such as emergency stop actuation, enabling faster system reactions to critical events—a vital feature for applications requiring split-second decisions.

Predictive Maintenance: New AI-driven diagnostic algorithms analyze real-time operational data to predict component wear and potential failures. This allows maintenance teams to schedule interventions before downtime occurs, particularly valuable in remote or hard-to-access installations like desert solar farms.

Hazardous Environment Compliance: The module’s ATEX and IECEx certifications (new for REV K) make it suitable for use in Zone 1/21 hazardous areas, expanding its applicability in oil & gas extraction, chemical processing, and other industries with strict safety requirements.

Redundant Reliability: Supporting dual 24V DC power inputs and auto-reconfiguration via GE’s Control System Toolbox, the IS220PDIAHIA, REV K ensures uninterrupted operation during power fluctuations or module replacements—critical for continuous-operation facilities like LNG terminals.

Backward Compatibility: Works seamlessly with legacy Mark VIe components (e.g., IS200JPDSG1ACB power modules), making it ideal for retrofitting older systems without full overhauls. This reduces upgrade costs by up to 30% compared to replacing entire control systems.

Application Areas

The GE IS220PDIAHIA, REV K excels in industries requiring precise monitoring of discrete signals:

The GE IS220PDIAHIA, REV K excels in industries requiring precise monitoring of discrete signals:

- Power Generation: Monitors turbine inlet valve limits, steam pressure switch status, and generator breaker positions, ensuring compliance with NERC standards. Its fast response time is critical for grid stabilization during load changes.

- Oil & Gas: Tracks valve positions in pipelines, compressor interlocks, and wellhead emergency shutdowns in hazardous zones (ATEX/IECEx-certified for Zone 1 areas). The predictive maintenance feature reduces unplanned shutdowns in offshore platforms.

- Marine Propulsion: Captures engine shutdown sensor signals, fuel valve status, and cooling system pressure switches in naval vessels, enhancing safety at sea. Its conformal coating protects against saltwater corrosion.

- Industrial Automation: Integrates with robotics to track machine guard positions, part presence sensors, and conveyor emergency stops in automotive plants. The reduced power consumption suits energy-sensitive manufacturing environments.

- Renewable Energy: Monitors solar inverter status, wind turbine brake interlocks, and battery storage system alarms in utility-scale renewable facilities. The wide temperature range ensures stability in both arctic and desert installations.

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation preparation: Before installing the IS220PDIAHIA, REV K, ensure the Mark VIe backplane is powered off and properly grounded. Verify compatibility with connected field devices (24V DC) and use shielded twisted-pair cables to minimize noise. Configure channel settings (NO/NC) using GE’s Control System Toolbox (v10.0+ required for REV K) and enable redundancy if dual power supplies are available. The module’s plug-and-play design simplifies installation, with no tools required for mounting.

Installation preparation: Before installing the IS220PDIAHIA, REV K, ensure the Mark VIe backplane is powered off and properly grounded. Verify compatibility with connected field devices (24V DC) and use shielded twisted-pair cables to minimize noise. Configure channel settings (NO/NC) using GE’s Control System Toolbox (v10.0+ required for REV K) and enable redundancy if dual power supplies are available. The module’s plug-and-play design simplifies installation, with no tools required for mounting.

Maintenance recommendations: Regularly inspect the IS220PDIAHIA, REV K for loose connections and dust accumulation, particularly in high-vibration areas. Leverage the module’s predictive maintenance dashboard to monitor component health and schedule firmware updates quarterly. Replace modules immediately if channels fail to respond, and clean ventilation slots annually to prevent overheating. GE’s remote diagnostics allow technicians to troubleshoot issues without on-site visits, reducing maintenance costs by up to 25%.

Product Warranty

GE provides a 1-year warranty for the IS220PDIAHIA, REV K, covering defects in materials and workmanship. This includes free replacement or repair, backed by a global network of certified technicians. For mission-critical applications, extended warranties (up to 5 years) and 24/7 technical support are available, ensuring rapid resolution of issues. GE’s commitment to quality ensures the IS220PDIAHIA, REV K delivers reliable performance in even the most demanding industrial environments, with a mean time between failures (MTBF) exceeding 100,000 hours.

GE provides a 1-year warranty for the IS220PDIAHIA, REV K, covering defects in materials and workmanship. This includes free replacement or repair, backed by a global network of certified technicians. For mission-critical applications, extended warranties (up to 5 years) and 24/7 technical support are available, ensuring rapid resolution of issues. GE’s commitment to quality ensures the IS220PDIAHIA, REV K delivers reliable performance in even the most demanding industrial environments, with a mean time between failures (MTBF) exceeding 100,000 hours.

HS:8471800000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com