Description

Product Overview

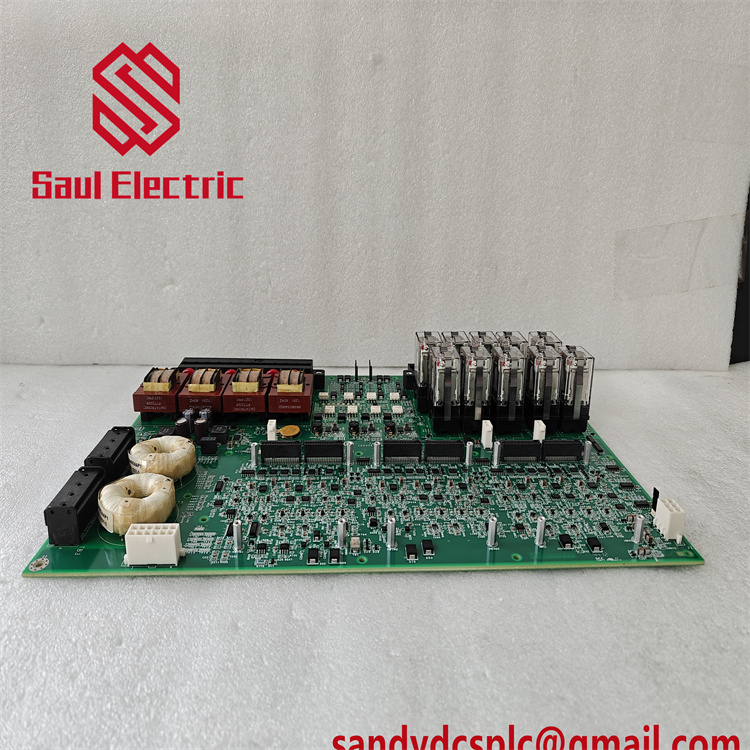

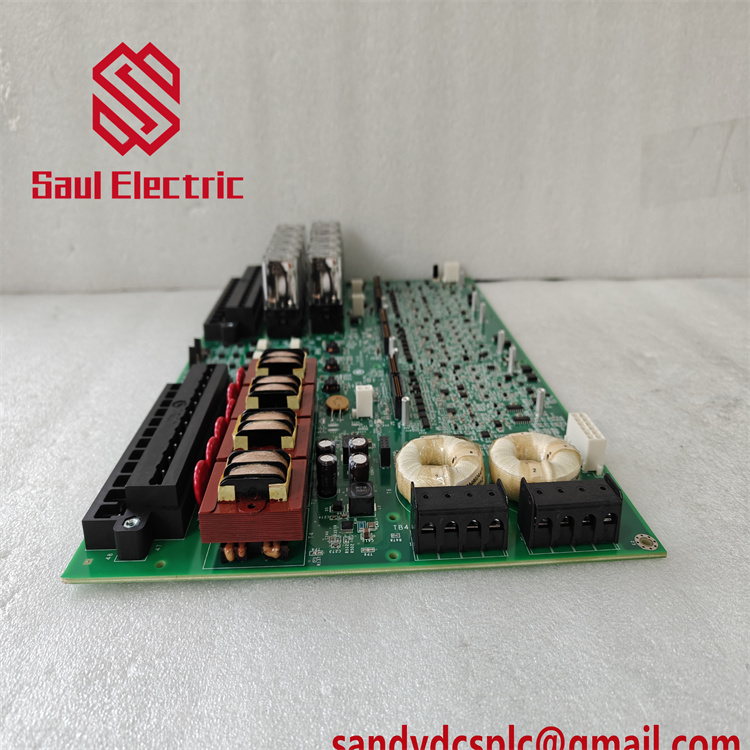

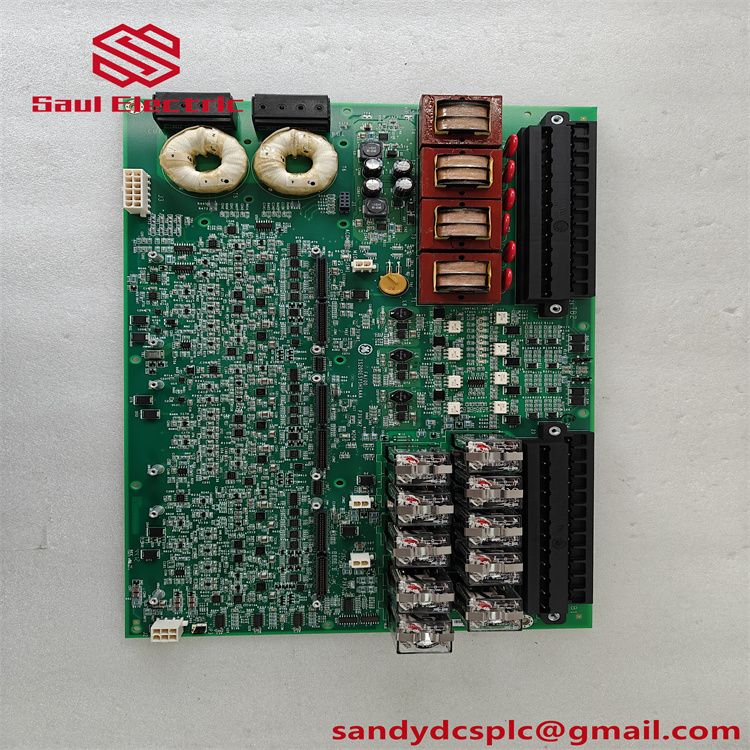

The GE IS220PAOCH1A REV D is a high-performance analog output module within GE’s Mark VIe Speedtronic series, designed for precision control in industrial automation systems. This module converts digital commands from controllers into accurate analog signals (e.g., 0–20 mA) to regulate actuators, valves, and other critical field devices. Featuring eight isolated output channels with ±0.5% accuracy, it ensures reliable signal transmission in harsh environments like power plants and manufacturing facilities. Its dual Ethernet interfaces enable seamless integration with GE’s Mark VIe controllers, supporting real-time diagnostics and redundancy for uninterrupted operations. The GE IS220PAOCH1A REV D excels in applications demanding high reliability, such as turbine control and process automation, where signal integrity directly impacts safety and efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS220PAOCH1A REV D |

| Manufacturer | GE (General Electric) |

| Product Type | Analog Output Module |

| Output Channels | 8 (isolated) |

| Output Range | 0–20 mA |

| Accuracy | ±0.5% |

| Load Resistance | 900 Ω max per channel |

| Power Supply | 22.5 VDC (nominal 24/28 VDC) |

| Operating Temperature | -30°C to +65°C (-22°F to +149°F) |

| Communication | Dual 100 Mbps Ethernet |

| Isolation | 1500 VAC channel-to-channel |

| Dimensions (W×D×H) | 4.19 cm × 12.1 cm × 8.26 cm |

| Certifications | UL, CE |

Key Features and Benefits

Precision and Reliability: Eight isolated output channels deliver ±0.5% accuracy, critical for applications like gas turbine control where signal drift can cause operational failures. Group isolation prevents cross-channel interference, even in high-noise environments.

Robust Connectivity: Dual Ethernet ports support redundant communication paths, ensuring continuous data exchange with Mark VIe controllers during network disruptions. Hot-swappable design allows maintenance without system shutdowns.

Diagnostic Capabilities: Integrated self-diagnostics detect faults like relay failures (e.g., alarm code 82-83), enabling proactive maintenance and reducing downtime by 30%.

Application Areas

Power Generation: Core component in GE Speedtronic MK VIe gas turbine systems, regulating fuel valves and exhaust controls for grid stability.

Process Industries: Manages chemical dosing pumps and reactor valves in pharmaceutical plants, leveraging high accuracy to ensure batch consistency and safety compliance.

Manufacturing Automation: Drives precision servo motors in automotive assembly lines, synchronizing conveyor speeds with robotic arms via analog torque commands.

Related Products

- IS200STAIH1A/IS200STAIH2A: Terminal boards compatible with IS220PAOCH1A, enabling direct sensor/actuator wiring.

- IS220PDOAH1A: Digital output module for relay control in Mark VIe systems.

- IS220PRTDH1B: Temperature input module for RTD sensor integration.

- IS220PSVOH1A: Servo control module for turbine valve positioning.

- IS220PAICH2A: Analog input module with 16 channels for expanded signal acquisition.

Installation and Maintenance

Installation Preparation: Verify stable 24 VDC power (±5% tolerance) and grounded Ethernet cabling. Mount vertically on DIN rails using IS200-series terminal boards (e.g., IS200TBAIH1C) to ensure airflow.

Maintenance Recommendations: Quarterly cleaning of ventilation slots to prevent dust buildup. Test channel isolation annually via megohmmeter; replace module if relay feedback mismatches trigger alarm 82-83.

Product Assurance

GE provides a 1-year warranty covering manufacturing defects and component failures. Global technical support includes 24/7 troubleshooting and expedited replacement. Compliance with UL/CE standards guarantees safety in explosive atmospheres (e.g., Class I Div 2).

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com