Description

📌 Product Overview

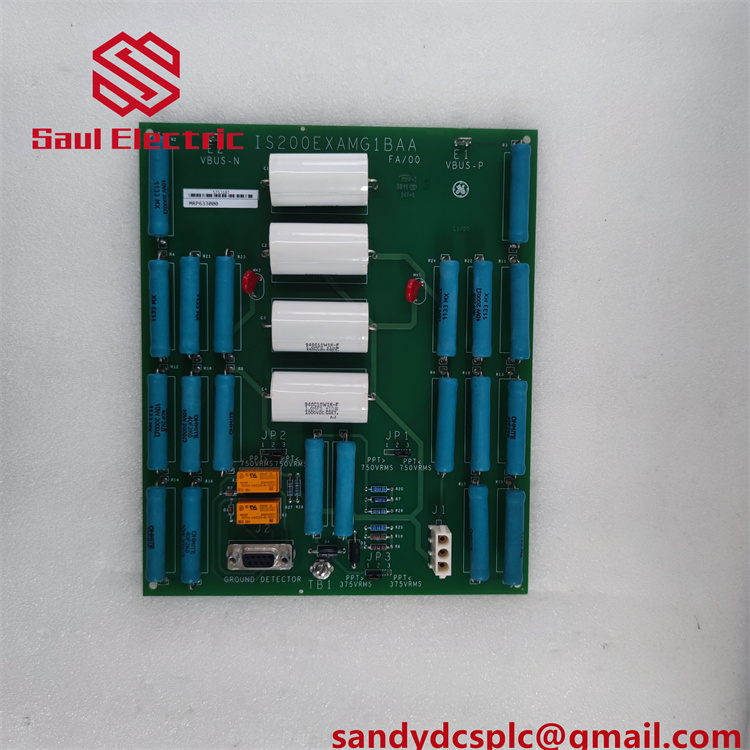

The GE IS220PAICH2A REV H is a high-performance Analog I/O Pack within GE’s Mark VIe industrial control system, engineered for precision signal processing in critical automation environments. Designed as an upgrade to earlier revisions, this module enhances channel density and environmental resilience, supporting 8 analog inputs (AI) and 4 analog outputs (AO) with 12-bit resolution for voltage/current signal conversion. Its ruggedized construction meets Class I, Division 2 hazardous area certifications (ATEX/IECEx), making it ideal for oil refineries, power plants, and chemical processing facilities where operational stability under extreme conditions is paramount.

⚙️ Technical Specifications

| Parameter | Value |

|---|---|

| Model | IS220PAICH2A REV H |

| I/O Channels | 8 AI + 4 AO |

| Input Types | ±10V DC, 0–20mA, 4–20mA |

| Output Types | 0–10V DC, 4–20mA (500Ω max load) |

| Resolution | 12-bit ADC/DAC |

| Power Supply | 20–30V DC (±5% tolerance) |

| Operating Temp | -40°C to +70°C (extended range vs. REV G) |

| Communication | Dual Ethernet RJ45 (Ethernet/IP, Modbus TCP) |

| Isolation Voltage | 1500V DC (channel-to-system) |

| Dimensions | 122 × 82 × 60 mm (L×W×H) |

| Weight | 0.38 kg |

| Ingress Protection | IP20 (dust-resistant) |

💡 Key Features & Advantages

- Enhanced Environmental Robustness

- Operates in -40°C to +70°C extremes, surpassing earlier revisions’ -20°C limit.

- Vibration resistance up to 1G for stability in turbine control or heavy machinery.

- Precision Signal Handling

- 12-bit ADC ensures ±0.05% accuracy for critical measurements (e.g., reactor pressure, turbine exhaust temp).

- Hardware-based noise filtering and channel isolation eliminate ground-loop interference.

- Seamless Integration

- Hot-swappable design enables maintenance without system shutdown.

- Auto-configuration via Proficy Toolbox software reduces commissioning time by 40%.

- Safety & Diagnostics

- Dual Ethernet ports support redundant communication paths.

- On-board LEDs and software-triggered alerts for wire-break detection and sensor drift.

🏭 Application Areas

- Power Generation: Turbine bearing temperature monitoring and boiler feedwater flow control in gas/steam plants.

- Oil & Gas: Wellhead pressure safety shutdown systems (SIL 2-rated) in Class I/Div. 2 zones.

- Chemical Processing: Real-time pH control in reactors using closed-loop analog outputs.

- Water Treatment: Chlorine dosage regulation via 4–20mA output to dosing pumps.

🔧 Installation & Maintenance

- Mounting: Vertical DIN-rail installation using TSVOH1D terminal board; ensure ≤0.1Ω ground resistance.

- Wiring: Shielded cables with ≥20 cm separation from AC power lines to prevent EMI.

- Maintenance:

- Annual calibration with Fluke 754 calibrator.

- Replace electrolytic capacitors after 50,000 operational hours (≈5.7 years).

- Firmware updates via ToolboxST v8.1+ (requires temporary network shutdown).

🔗 Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

🛡️ Product Assurance

- Warranty: 12–18 months global coverage for material/workmanship defects.

- Compliance: UL E207685, ATEX Zone 2, IEC 61508 (SIL 2).

- Support: 24/7 remote diagnostics + 48-hour on-site response for critical failures.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com