Description

Product Overview

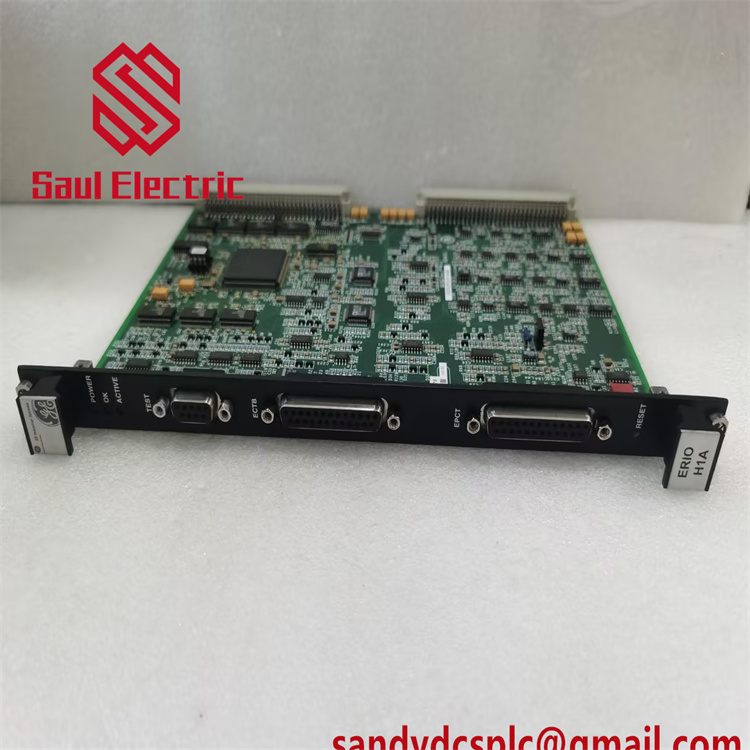

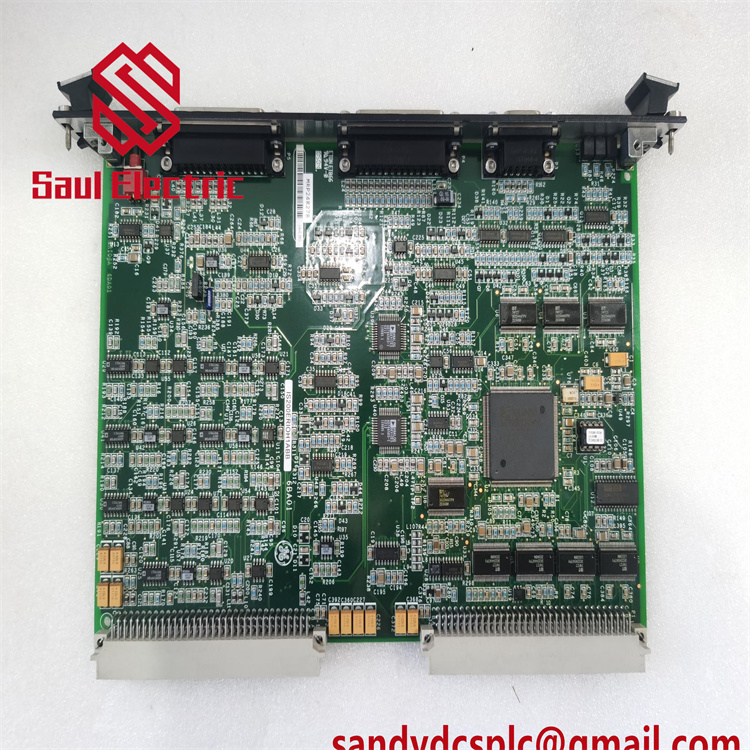

The GE IS220PAICH2A, REV D is a versatile Analog Input/Output (I/O) Pack developed by General Electric for the Mark VIe Speedtronic Turbine Control System. Engineered for industrial automation, this module excels in precise signal acquisition and control, interfacing with sensors (e.g., pressure transducers, temperature sensors) and actuators to convert analog signals into digital data for real-time monitoring. As a core component of GE’s Mark VIe platform, the GE IS220PAICH2A, REV D supports 16 input and 16 output channels with programmable functionality, enabling flexible integration into complex control strategies for gas turbines, compressors, and critical machinery

Its robust design operates reliably in harsh environments (–40°C to +70°C) with IP20-rated protection against dust, ensuring stability in power plants, oil refineries, and manufacturing facilities. Dual Ethernet ports facilitate seamless data exchange via industrial protocols like Modbus TCP and EtherNet/IP, while embedded diagnostics reduce downtime through proactive fault detection

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PAICH2A, REV D |

| Manufacturer | General Electric (GE) |

| Product Type | Analog I/O Pack |

| Input/Output Channels | 16 inputs + 16 outputs (programmable) |

| Input Voltage Range | 0–10V DC |

| Input Current Range | 4–20mA |

| Output Voltage Range | 0–10V DC |

| Output Current Range | 4–20mA (supports loads ≤500Ω) |

| Resolution | 12-bit |

| Power Supply | 24V DC (20–30V DC range) |

| Power Consumption | ~5W |

| Operating Temperature | –40°C to +70°C |

| Dimensions | 124 × 107 × 38 mm (4.88″ × 4.22″ × 1.50″) |

| Weight | 0.32 kg (0.7 lbs) |

| Protection Rating | IP20 |

| Certifications | UL, CE, ISO 9001

1

3

6

|

Key Features and Advantages

Precision Signal Handling:

With 12-bit resolution and ±0.1% accuracy, the GE IS220PAICH2A, REV D ensures reliable data conversion for critical parameters like pressure and temperature. Inputs/outputs support configurable ranges (0–10V, 4–20mA), while channel isolation (1,500V AC) eliminates ground-loop interference in electrically noisy environments (e.g., steel mills)

Robust Industrial Design:

The module’s conformal-coated PCB and IP20 housing resist dust ingress and operate flawlessly in extreme temperatures (–40°C to +70°C). Vibration resistance (1G tolerance) ensures stability in turbine control applications, and hot-swappable architecture allows maintenance without system shutdowns

Seamless Integration:

Dual Ethernet ports enable redundant communication via EtherNet/IP, Modbus TCP, or DNP3.0, integrating with Mark VIe controllers (e.g., IS215UCVEH2AB). Built-in diagnostic LEDs and ToolboxST software detect faults (open-circuit/short-circuit) in real-time, reducing troubleshooting efforts by 40%

Application Areas

- Power Generation: Monitors turbine bearing temperatures and exhaust pressures, triggering SIL 2 shutdowns to prevent rotor damage

- Oil & Gas: Controls valve actuators and flow meters in compressor stations, withstanding methane exposure (ATEX Zone 2) and humidity up to 95%

- Water Treatment: Manages chemical dosing pumps and level sensors, ensuring precise control in corrosive environments

Related Products

- IS200TSVCH2A: Terminal board for sensor interfacing with the IS220PAICH2A, REV D

- IS215UCVEH2AB: Mark VIe controller for centralized data processing

- IS220PVIBH1A: Vibration monitoring module for complementary mechanical diagnostics

- IC693PWR331G: 24V DC redundant power supply for backup scenarios

- Bently Nevada 3300 Proximitor: Eddy-current probe for vibration/temperature synergy

Installation and Maintenance

Installation: Mount vertically on DIN rails or 19″ control panels, ensuring ≥20 mm clearance from high-voltage sources. Use shielded twisted-pair cables (AWG 18–22) for analog signals, with ground resistance ≤0.1Ω. Verify stable 24V DC input (20–30V range) before startup

Maintenance: Calibrate I/O channels annually using a Fluke 744 calibrator. Clean terminals quarterly with dry nitrogen (<30 psi) to prevent conductive dust accumulation. Replace after 60,000 operational hours (≈7 years) to mitigate capacitor aging

Product Assurance

GE offers a 12-month global warranty covering material defects. Units undergo MIL-STD-810H testing (thermal cycling, vibration) with an MTBF exceeding 150,000 hours. Support includes 24/7 remote diagnostics and 48-hour emergency replacement for critical failures

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com