Description

Product Overview

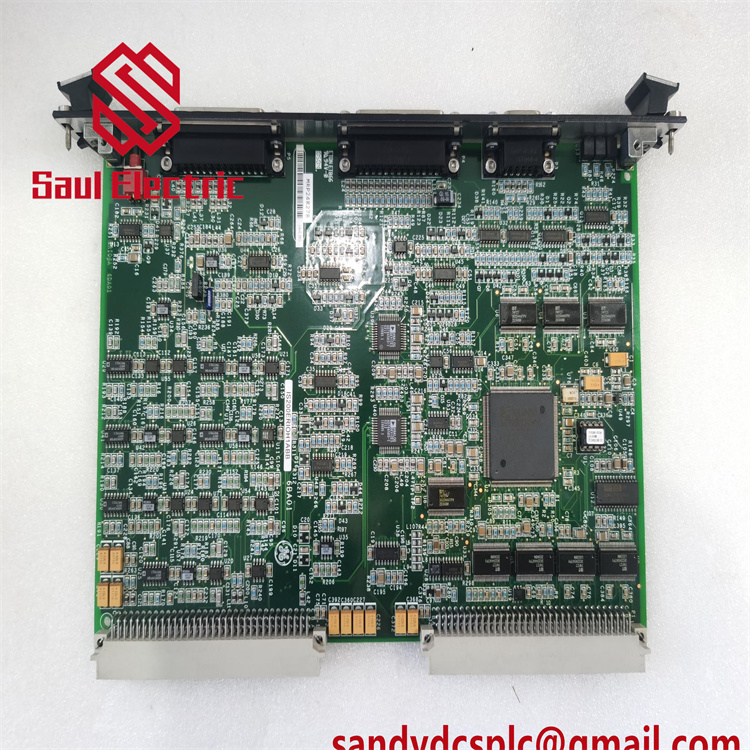

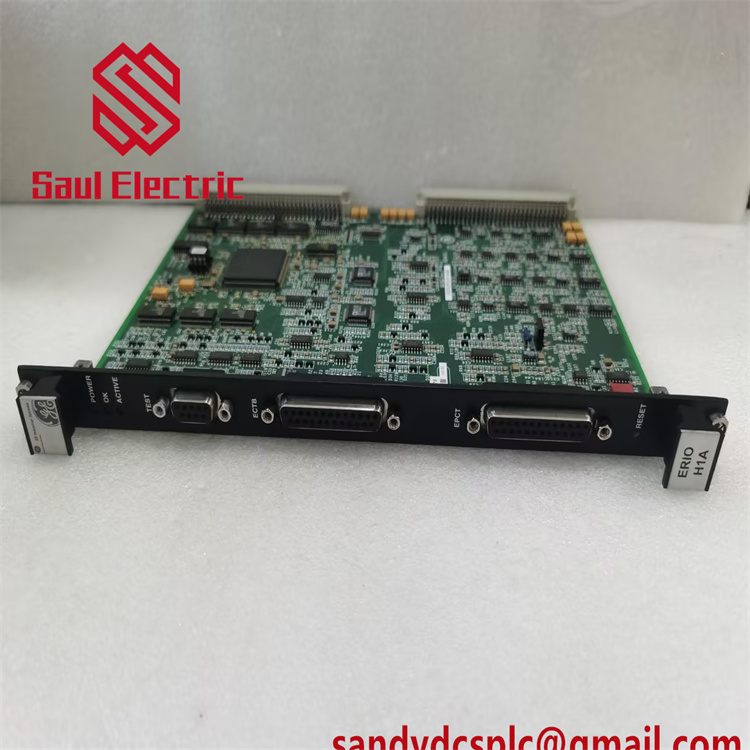

The GE IS220PAICH1A REV G is a high-precision Analog I/O Pack within GE’s Mark VIe industrial control system, engineered for critical data acquisition in hazardous and non-hazardous environments. This module integrates advanced signal conditioning circuitry to process analog inputs (e.g., 4–20 mA, RTD, thermocouple) and outputs with ±0.05% accuracy, enabling real-time monitoring of parameters like pressure, temperature, and flow rates in demanding industrial processes. Designed for seamless compatibility with Mark VIe controllers, the IS220PAICH1A REV G features dual Ethernet ports for redundant communication and supports protocols including Modbus TCP and EtherNet/IP. Its ruggedized construction complies with Class I, Division 2 safety standards (ANSI/ISA 12.12.01-2015), ensuring reliable operation in oil refineries, chemical plants, and power generation facilities where explosive atmospheres may exist.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PAICH1A REV G |

| Manufacturer | GE (General Electric) |

| Product Type | Analog Input/Output Module |

| Input Voltage | 27.4–28.6 V DC (nominal 28V DC) |

| Analog Inputs | 8 channels (supports RTD, thermocouple, ±10V, 4–20 mA) |

| Analog Outputs | 4 channels (4–20 mA or 0–10V programmable) |

| Accuracy | ±0.05% full scale |

| Isolation Voltage | 1500V DC (channel-to-system) |

| Communication Ports | 2 × 10/100 Ethernet RJ45 |

| Operating Temperature | -22°F to +149°F (-30°C to +65°C) |

| Hazard Certification | Class I, Div. 2, Groups A–D (ATEX/IECEx equivalent) |

| Dimensions | 120 × 80 × 40 mm (standard Mark VIe module size) |

| Weight | 0.36 kg |

Key Features and Advantages

1. Precision Signal Handling

16-bit ADC/DAC resolution and hardware-based noise filtering achieve laboratory-grade measurement stability, critical for pH control in chemical reactors or turbine bearing temperature monitoring.

2. Hazardous Environment Resilience

Conformal-coated PCB and IP20-rated housing (upgradable to IP54 with enclosure) resist humidity, chemical corrosion, and particulate ingress. UL E207865 certification ensures safety in hydrocarbon processing zones.

3. Simplified Integration

Hot-swappable design allows module replacement without system shutdown. Auto-calibration via GE’s Proficy Toolbox software reduces commissioning time by 40% compared to legacy I/O modules.

4. Predictive Diagnostics

On-board LEDs and software-triggered alerts monitor channel health, detecting wire breaks or sensor drift before process deviations occur. Field-upgradable firmware extends functional lifecycle.

Application Areas

- Oil & Gas: Wellhead pressure monitoring and safety shutdown (SIS) systems in Class I/Div. 2 zones.

- Power Generation: Turbine exhaust temperature profiling and boiler feedwater flow control.

- Chemical Processing: Reactor mass balance calculations via coriolis flow meter integration.

- Water Treatment: Chlorine dosage control using pH/ORP closed-loop output.

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation Preparation: Mount vertically on DIN rail using TSVOH1D terminal board. Maintain ≥20 cm clearance from high-voltage cables. Ground resistance ≤0.1Ω is mandatory for noise immunity.

Maintenance Recommendations: Calibrate analog channels annually using Fluke 754 documenting calibrator. Replace cooling fans after 60,000 operational hours (≈7 years). Firmware updates require ToolboxST v8.1 or later.

Product Assurance

GE provides an 18-month global warranty covering material and workmanship defects. Critical failure support includes 24/7 remote diagnostics and 48-hour on-site response for SIL 2/SIL 3 applications. All modules undergo 168-hour burn-in testing per IEC 61131-2 standards.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com