Description

Product Overview

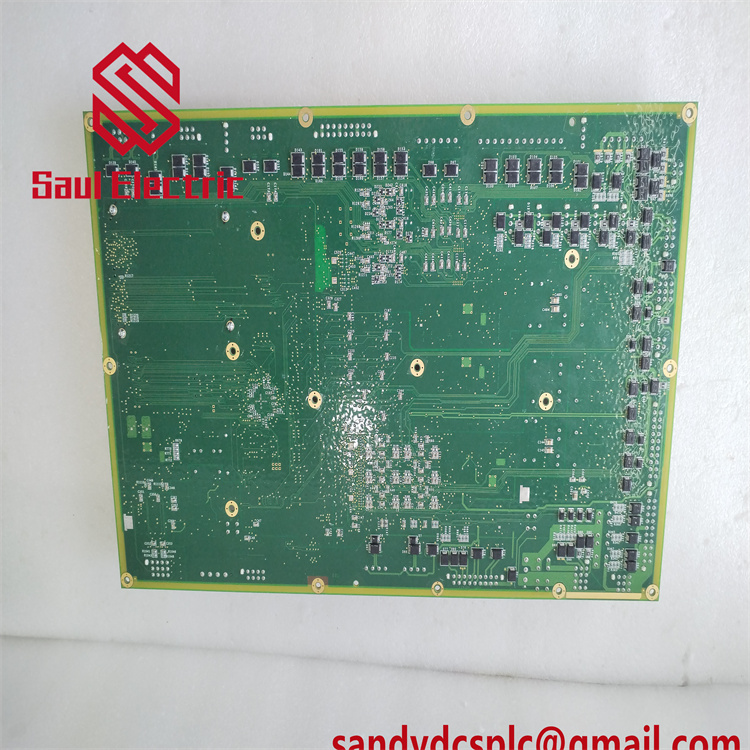

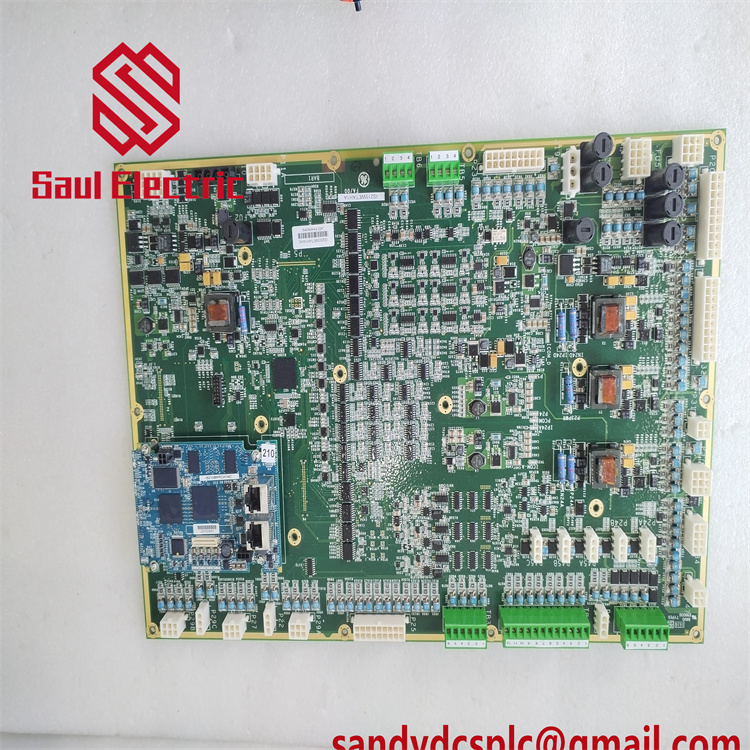

The GE IS215WETAH1A is a Torque Axis Control Board designed for GE’s Mark VIe Speedtronic Turbine Control System, specialized in managing torque control and dynamic load regulation for wind turbines. As part of the Mark VIe ecosystem, this module optimizes power transmission by adjusting torque output in real-time, ensuring stable grid connection and minimizing mechanical stress on drivetrain components. It features a rugged industrial design with conformal coating to withstand harsh environments, including offshore nacelles and high-vibration settings .

Key functions include real-time torque feedback processing, support for simplex or dual redundancy configurations, and compatibility with GE’s ControlST software for programmable logic control. The board interfaces with Ionet communication networks and distributed I/O modules to enable seamless integration with turbine supervisory systems .

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | GE IS215WETAH1A |

| Manufacturer | General Electric (GE) |

| Product Type | Wind Energy Torque Axis Control Board |

| Series | Mark VIe (Wind Turbine Control) |

| PCB Coating | Conformal coating (anti-moisture, dust, EMI) |

| I/O Configuration | 12 analog inputs (torque/speed sensors), 16 discrete inputs, 8 relay outputs, 2 RS-485 ports, 1 Ethernet (Ionet) interface |

| Communication | Ionet, UDH (User Datagram Handler), Modbus TCP |

| Power Supply | 24 V DC ±10% (nominal) |

| Operating Temperature | -40°C to +70°C (extended industrial grade) |

| Dimensions | ~24.8 cm (H) x 17.5 cm (W) x 4.5 cm (D) (approximate) |

| Weight | ~0.5 kg (1.1 lbs) |

| Compatibility | GE Mark VIe systems, ControlST v9.0+ |

| Revision | 1A (initial release) |

Key Features & Advantages

Precision Torque Management

- Adjusts turbine torque output based on wind speed, grid demand, and drivetrain health to optimize energy conversion efficiency .

- Integrates with encoder feedback for real-time speed-torque curve calibration, reducing gearbox wear and improving system longevity .

Rugged Design for Harsh Environments

- Conformal-coated circuitry resists salt fog, humidity, and dust, making it suitable for offshore and coastal wind farms .

- Wide temperature range (-40°C to +70°C) ensures reliability in extreme climates .

Scalable Redundancy & Diagnostics

- Supports hot-swappable redundancy (when paired with IS215WETAH1B) for zero downtime during maintenance .

- Built-in self-diagnostics monitor voltage, temperature, and communication health, with fault codes reported via Ionet .

System Integration

- Works alongside GE’s IS215WEPAH2B (Pitch Control Board) and IS215WEMAH1A (Main Control Board) to form a complete turbine control suite .

- Compatible with TMR (Triple Modular Redundancy) architectures for SIL-rated safety systems .

Application Areas

-

Wind Energy Generation:

- Onshore/offshore wind turbines (1.5MW–5MW class) for torque control and grid synchronization.

- Drivetrain protection systems to prevent overload during sudden wind gusts.

-

Industrial Drivetrains:

- Heavy machinery in manufacturing (e.g., conveyor systems, presses) requiring dynamic torque regulation.

- Marine applications (ship propulsion) for smooth power transmission.

-

Renewable Energy Storage:

- Hybrid wind-solar systems that require precise torque management for energy storage integration.

Related Products

- GE IS215WEPAH2B: Wind Energy Pitch Axis Control Board (complementary to torque control).

- GE IS215WEMAH1A: Wind Energy Main Cabinet Board (central data processing).

- GE IS215UCVEM09B: VME Controller Board (system master for Mark VIe).

- GE IS215WETAH1B: Updated revision with enhanced diagnostic interfaces (backward compatible with 1A).

Installation & Maintenance

Installation Notes:

- Mount vertically in a 19-inch rack or control panel using GE-provided brackets.

- Use shielded cables for analog inputs to minimize EMI interference; ground the board chassis to prevent static discharge.

- Configure I/O mapping and torque limits via ControlST software, referencing GE’s Turbine Control Application Manual.

Maintenance Schedule:

- Quarterly: Inspect for loose connections, corrosion, or thermal stress on components.

- Annual: Update firmware to the latest version (available via GE Digital Services) to address bug fixes and security patches.

- Preventive Replacement: Replace electrolytic capacitors every 5 years (expected lifespan in industrial environments).

Warranty & Availability

- Warranty: 12-month manufacturer’s warranty against defects.

- Inventory Status:

- In-stock items: Shipped within 3–5 business days after payment.

- Backorders: Lead time ~4–6 weeks (subject to GE production schedules).

- Support Channels:

- GE Vernova’s Mark VIe Support Team for technical documentation and troubleshooting (requires customer login).

- Authorized service centers for on-site repair/replacement.

Technical Note

The IS215WETAH1A is part of GE’s legacy Mark VIe product line, designed for systems where high-reliability torque control is critical. For newer installations, consider the IS215WETAH1B (Revision 1B) for improved cybersecurity features and extended compatibility with GE’s Predix digital platform. Always verify compatibility with your turbine model before ordering.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com