Description

Product Overview

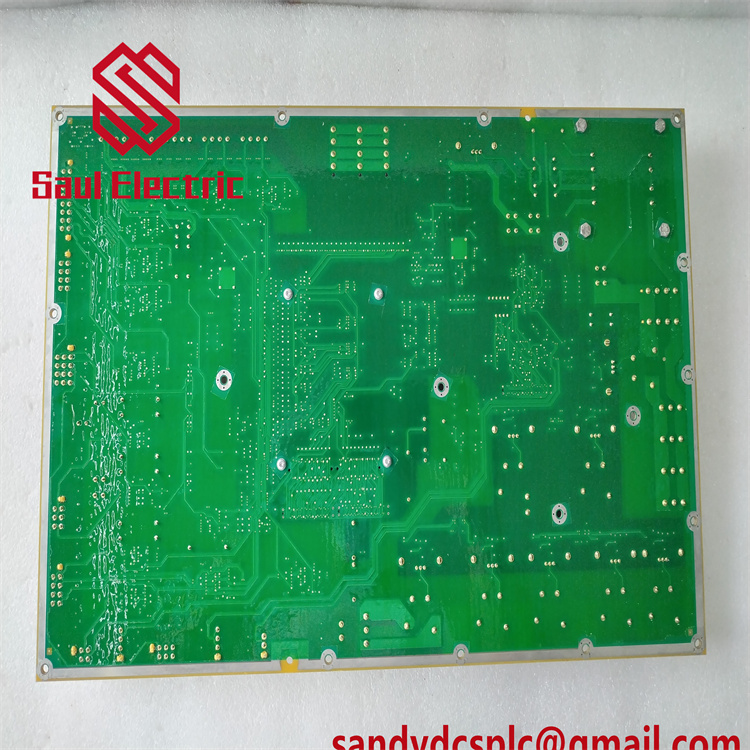

The GE IS215WEMAH1A is a Wind Energy Main Cabinet Board designed for GE’s Mark VIe Turbine Control System, specifically optimized for wind turbine applications. This module serves as a critical interface for managing input/output (I/O) signals, real-time data processing, and grid synchronization in wind energy systems. Its rugged design with conformal coating ensures reliable operation in harsh environments, including offshore wind farms and high-vibration settings 115.

Key components include relays, solid-state switches, thermistor inputs, and digital signal processing circuitry. The board supports 27 digital inputs, 9 relay contact outputs, and 3 solid-state relay outputs, enabling precise control of turbine pitch, yaw, and generator excitation. Its dual analog thermistor inputs monitor temperature variations in critical components like gearboxes and generators 15.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | GE IS215WEMAH1A |

| Manufacturer | General Electric (GE) |

| Product Type | Wind Energy Main Cabinet Board |

| Series | Mark VIe (Wind Turbine Control) |

| PCB Coating | Conformal coating for environmental protection |

| Components | Relays, solid-state switches, thermistors, transformers, fuses |

| Connectors | Six 3-pin connectors, terminal strips for signal routing |

| Input/Output | 27 digital inputs, 9 relay contact outputs, 3 solid-state outputs |

| Analog Sensors | 2 analog thermistor inputs (0-20 mA) |

| Operating Temperature | -30°C to +65°C (industrial grade) |

| Physical Dimensions | ~26.41 cm (height) x 21.33 cm (width) (approximate) |

| Weight | ~0.6 kg (1.32 pounds) |

| Compatibility | GE Mark VIe Wind systems, ControlST software |

| Functional Revision | 1A |

Key Features and Advantages

Rugged Environmental Design:

- Conformal coating and robust PCB construction protect against moisture, dust, and electromagnetic interference (EMI), making it suitable for offshore and high-humidity environments 15.

- Factory-drilled mounting holes allow secure rack or panel installation in wind turbine nacelles 15.

Precision Signal Management:

- Supports real-time monitoring of critical parameters such as wind speed, rotor speed, blade pitch angle, and generator output voltage 515.

- Dual thermistor inputs provide temperature feedback for predictive maintenance, reducing downtime in gearbox and generator systems 15.

Grid Integration and Safety:

- Manages grid synchronization by regulating output voltage and frequency to meet utility requirements, ensuring seamless integration with the power grid 5.

- Includes safety features like overspeed protection, overvoltage detection, and emergency shutdown protocols to safeguard turbine assets 5.

Scalable Redundancy:

- Backward compatible with the obsolete IS215WEMAH1A (revision 1A), allowing incremental system upgrades without full replacement 15.

- Supports simplex configurations for cost-effective setups or redundant architectures for mission-critical applications 15.

Application Areas

The GE IS215WEMAH1A excels in industries requiring reliable wind energy control:

- Wind Energy: Integrates with Mark VIe Wind systems to manage turbine pitch, yaw, and grid synchronization, particularly in offshore wind farms 115.

- Renewable Energy: Supports hybrid systems combining wind and solar power, optimizing energy capture and distribution 5.

- Industrial Automation: Deployed in manufacturing plants for process control and equipment monitoring in high-EMI environments 5.

- Oil and Gas: Used in offshore platforms for pump and compressor control, leveraging its environmental resilience 5.

Related Products

- GE IS215WEMAH1BA: Upgraded version with B-rated functional revision, offering enhanced signal processing and backward compatibility 15.

- GE IS215UCCCS05A: Mark VIES Safety Controller Board for SIL 2/SIL 3-certified safety systems, complementary for redundant control setups 13.

- GE IS210AEPSG1BCA: Alternative Energy Power Supply Module for stable power distribution in wind turbine control systems 13.

- GE IS215UCVEM09B: VME Controller Board for Mark VI systems, enabling high-speed data communication with the IS215WEMAH1A 4.

Installation and Maintenance

Installation Preparation:

- Verify the installation environment meets temperature (-30°C to +65°C) and humidity requirements.

- Use GE-approved mounting brackets and shielded cables to minimize EMI interference.

- Configure the board via GE’s ControlST software to define I/O mapping and safety thresholds 15.

Maintenance Recommendations:

- Routine Checks: Inspect for loose connections, corrosion, or overheating. Clean dust from vents to maintain cooling efficiency.

- Firmware Updates: Regularly update firmware to access new features and security patches (contact GE for updates).

- Redundancy Testing: Simulate signal failures to validate fault isolation capabilities.

- Component Replacement: Replace worn-out relays or fuses with GE-certified parts to ensure compatibility 15.

Product Warranty and Support

The GE IS215WEMAH1A comes with a 1-year warranty covering defects in materials and workmanship. For immediate deployment, the module is available in spot inventory and ships within 3–5 days of payment. Backorders are fulfilled within 1 month 515.

GE offers 24/7 technical support and access to a global network of certified engineers for system integration, troubleshooting, and training. However, due to limited publicly available documentation, detailed technical guidance may require direct consultation with GE Vernova’s Mark VIe support team 115.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com