Description

Product Overview

The GE IS200WETCH1A is a high-performance Top Box Module C Board Assembly engineered for critical wind turbine control systems within GE’s Mark VIe Speedtronic platform. Designed as a core component of the Mark VIe Wind series, this module serves as a vital interface for signal conditioning, power distribution, and system integration in wind energy applications. Its rugged construction and advanced circuitry make it ideal for offshore wind farms, power generation facilities, and industrial environments requiring reliable turbine management under extreme conditions.

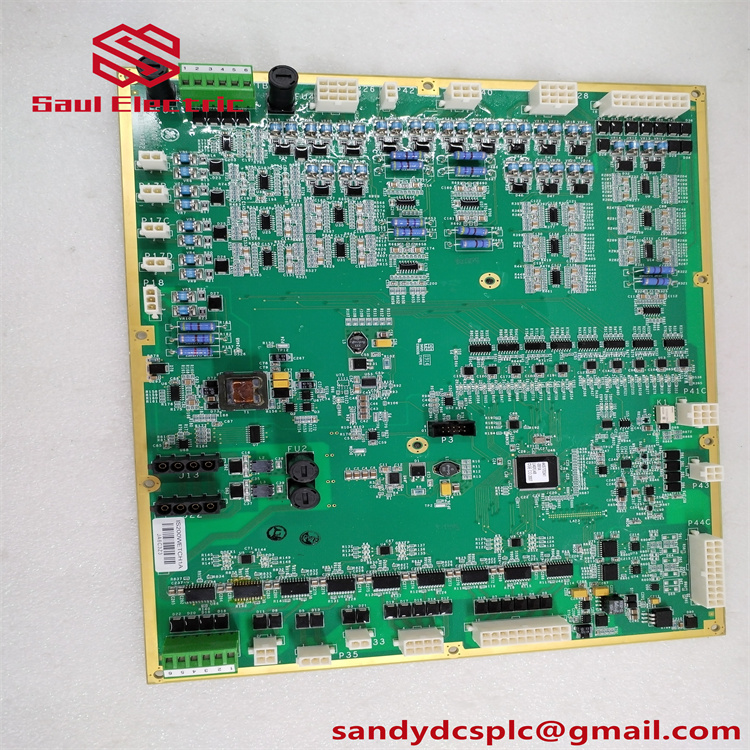

Featuring a conformal-coated PCB and robust components, the GE IS200WETCH1A incorporates four fuses, a transformer, and two six-position terminal strips for secure signal routing and power regulation 313. The board includes forty-four voltage regulators, two inductor coils, and multiple relays to ensure stable performance in high-vibration and high-humidity settings. Its exposed copper band perimeter provides enhanced insulation and grounding, while factory-drilled mounting holes enable secure panel or rack installation 513. As part of GE’s Speedtronic legacy, the GE IS200WETCH1A supports seamless integration with ControlST software, facilitating real-time monitoring and diagnostic capabilities for optimized turbine operations.

Certified for industrial use, the GE IS200WETCH1A interfaces with GE’s EX2100 excitation control system and Mark VIe backplanes, ensuring compatibility with redundant configurations and scalable system designs 59. Its modular architecture allows for easy replacement of components like relays and capacitors, minimizing downtime during maintenance. By combining high-speed data processing with environmental resilience, the GE IS200WETCH1A sets a benchmark for reliability in wind turbine control systems.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | GE IS200WETCH1A |

| Manufacturer | General Electric (GE) |

| Product Type | Top Box Module C Board Assembly |

| Series | Mark VIe Wind |

| Functional Revision | 1A |

| PCB Coating | Conformal coating for environmental protection |

| Components | 4 fuses, 1 transformer, 2 terminal strips (6 positions each), 44 voltage regulators, relays, inductors, resistors, capacitors |

| Input/Output | 12-channel terminal strips for analog/digital signals |

| Mounting Options | Rack or panel mounting with factory-drilled holes |

| Operating Temperature | -30°C to +70°C (industrial grade) |

| Physical Dimensions | 25 cm x 18 cm x 5 cm (W x H x D) (approximate) |

| Weight | 1.2 kg (approximate) |

| Compatibility | GE Mark VIe Speedtronic systems, EX2100 excitation control |

| Communication | GE ISBus protocol (proprietary) |

Key Features and Advantages

Rugged Environmental Protection: The GE IS200WETCH1A’s conformal coating and copper band perimeter protect against dust, moisture, and electromagnetic interference, ensuring longevity in offshore wind farms and harsh industrial settings 513. Its wire-wound resistors and heat sinks enable stable performance under extreme temperatures and vibrations.

Precision Signal Management: With dual six-position terminal strips and integrated voltage regulators, the module ensures accurate signal conditioning for turbine sensors and actuators. Its differential inputs and advanced filtering minimize noise, critical for maintaining grid synchronization and power output stability 313.

Seamless System Integration: As part of GE’s Mark VIe series, the GE IS200WETCH1A interfaces seamlessly with ControlST software and other modules like the IS200WETBH1A (Top Box B Board) and IS200WETAH1AEC (Gas Turbine Board) 9. This compatibility streamlines system setup and reduces integration complexity.

Redundancy and Fault Isolation: The module supports simplex and redundant configurations, with diagnostic LEDs providing real-time status updates for rapid fault detection. Its hot-swappable design allows for online maintenance without disrupting operations, enhancing operational efficiency 513.

High-Speed Data Processing: Optimized for real-time data transmission, the GE IS200WETCH1A ensures timely signal processing for precise turbine control, critical for grid stability and power generation efficiency in wind energy applications.

Application Areas

The GE IS200WETCH1A excels in industries where reliable turbine control and signal management are essential:

- Wind Energy: Integrates with Mark VIe Wind systems to manage turbine excitation, pitch control, and grid synchronization, particularly in offshore wind farms requiring high reliability in harsh environments 514.

- Power Generation: Supports gas and steam turbine control systems, monitoring parameters like temperature, pressure, and rotational speed to optimize generator output and safety.

- Industrial Automation: Deployed in manufacturing plants for process control and equipment monitoring, especially in environments with high electromagnetic interference.

- Oil and Gas: Used in offshore platforms and refineries to manage I/O signals for pumps, compressors, and safety systems, ensuring compliance with operational standards.

- Water Treatment: Manages control signals for pumps and filtration systems, maintaining consistent water quality and system reliability.

Its compatibility with GE’s EX2100 excitation control system makes it a preferred choice for applications requiring fail-safe operation and precise voltage regulation.

Related Products

Installation and Maintenance

Installation Preparation:

Ensure the installation environment meets the module’s temperature and humidity requirements. Verify proper grounding and surge protection to prevent electromagnetic interference. Use GE-approved mounting brackets and cables for secure installation. Before powering up, configure the module via GE’s ControlST software to match the system’s I/O requirements and signal types 513.

Ensure the installation environment meets the module’s temperature and humidity requirements. Verify proper grounding and surge protection to prevent electromagnetic interference. Use GE-approved mounting brackets and cables for secure installation. Before powering up, configure the module via GE’s ControlST software to match the system’s I/O requirements and signal types 513.

Maintenance Recommendations:

- Routine Checks: Inspect for physical damage, loose connections, or signs of overheating. Clean dust from the module’s vents to maintain optimal cooling.

- Firmware Updates: Regularly update firmware to access new features and security patches, ensuring compatibility with the latest system upgrades.

- Redundancy Testing: Periodically test the module’s fault isolation capabilities by simulating signal failures to validate system continuity.

- Component Replacement: Replace worn-out relays or capacitors as needed, using GE-certified spare parts to maintain performance.

The GE IS200WETCH1A’s modular design simplifies component replacement, and its diagnostic LEDs provide real-time status updates for quick troubleshooting.

Product Warranty and Support

The GE IS200WETCH1A comes with a 1-year warranty covering defects in materials and workmanship. For immediate deployment, the module is available in spot inventory and ships within 3 days of payment. Backorders are fulfilled within 1 month, ensuring timely delivery for large-scale projects 59.

GE offers 24/7 technical support and access to a global network of certified engineers for system integration, troubleshooting, and training. Comprehensive documentation, including datasheets and installation manuals, is provided to facilitate seamless deployment. With a commitment to quality and reliability, GE ensures the GE IS200WETCH1A delivers long-term performance in the most demanding industrial environments.

pinterest:https://pin.it/51q0kjRoB

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com