Description

Product Overview

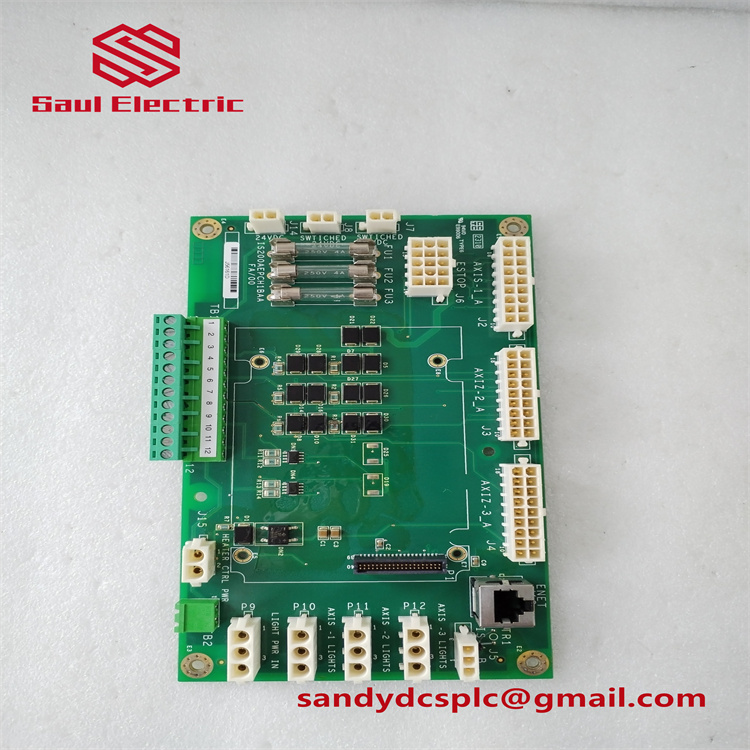

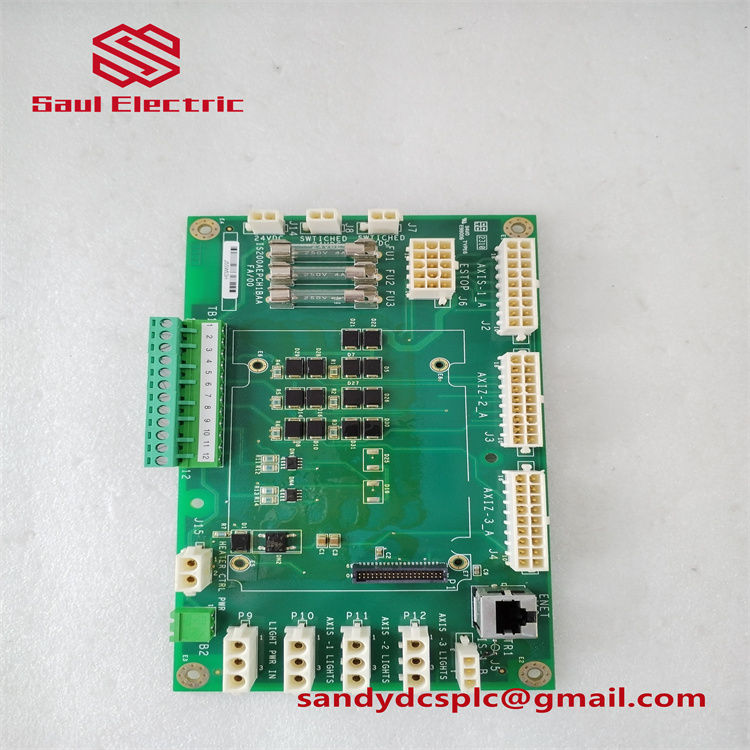

The GE IS200TRPGHIBDD is a specialized Generator Power Terminal Board designed for GE’s Mark VIe turbine control system, a cornerstone of industrial automation in power generation, oil & gas, and heavy machinery. As a critical interface between generator sensors and the central controller, this terminal board manages high-voltage and current signals, ensuring accurate monitoring of generator performance in mission-critical environments. Part of GE’s Mark VIe distributed I/O architecture, the IS200TRPGHIBDD enables seamless integration with power-related sensors, making it indispensable for stable generator operation and grid synchronization.

The GE IS200TRPGHIBDD is a specialized Generator Power Terminal Board designed for GE’s Mark VIe turbine control system, a cornerstone of industrial automation in power generation, oil & gas, and heavy machinery. As a critical interface between generator sensors and the central controller, this terminal board manages high-voltage and current signals, ensuring accurate monitoring of generator performance in mission-critical environments. Part of GE’s Mark VIe distributed I/O architecture, the IS200TRPGHIBDD enables seamless integration with power-related sensors, making it indispensable for stable generator operation and grid synchronization.

Featuring 12 isolated input channels, the IS200TRPGHIBDD supports both analog (0-10V, 4-20mA) and high-voltage discrete signals (up to 250V AC), accommodating devices like current transformers, voltage transducers, and generator breaker status sensors. Its 48-terminal design (24 per block) allows flexible wiring in complex power systems, while DC-37 pin connectors ensure secure connectivity. The board’s conformal-coated PCB and -30°C to +65°C operating range enhance durability in harsh conditions, from high-vibration turbine halls to humid power plant environments.

Key to its functionality is the IS200TRPGHIBDD’s 4kVrms channel isolation (higher than standard terminal boards) and advanced surge protection, which prevent signal interference from high-voltage transients—critical for maintaining accuracy in generator control systems. Its diagnostic features, including real-time fault detection and LED status indicators, simplify troubleshooting, reducing downtime by enabling quick identification of issues like loose connections or sensor failures. This combination of specialized power signal handling, ruggedness, and diagnostic intelligence makes the IS200TRPGHIBDD essential for reliable generator operation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TRPGHIBDD |

| Manufacturer | General Electric (GE) |

| Product Type | Generator Power Terminal Board |

| Series | Mark VIe |

| Number of Channels | 12 (isolated) |

| Supported Signals | Analog (0-10V, 4-20mA), Discrete (up to 250V AC) |

| Terminal Count | 48 (24 per block) |

| Connector Type | 2 x DC-37 pin (female) |

| Isolation Rating | 4kVrms (per channel) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 285 mm x 62 mm x 30 mm (11.22″ x 2.44″ x 1.18″) |

| Weight | ~0.5 kg |

| Certifications | UL 508, CE, CSA, IEC 61010 |

Main Features and Advantages

High-Voltage Signal Handling: The IS200TRPGHIBDD is engineered to manage signals up to 250V AC, making it ideal for connecting to generator current transformers, voltage transducers, and breaker status sensors—critical components in power generation where accurate voltage/current monitoring ensures grid stability.

High-Voltage Signal Handling: The IS200TRPGHIBDD is engineered to manage signals up to 250V AC, making it ideal for connecting to generator current transformers, voltage transducers, and breaker status sensors—critical components in power generation where accurate voltage/current monitoring ensures grid stability.

Enhanced Isolation: With 4kVrms channel isolation (higher than standard terminal boards), the module prevents cross-talk between high-voltage power signals and low-voltage control circuits, reducing the risk of interference-induced errors in generator synchronization and load management.

Rugged Design: The conformal-coated PCB and -30°C to +65°C operating range ensure durability in harsh environments, including high-humidity power plants, desert solar farms, and offshore generator facilities, where dust, moisture, and temperature extremes are common.

Integrated Diagnostics: LED indicators for power, channel activity, and faults provide real-time system health visibility, while built-in alarms for overvoltage, open circuits, and signal degradation enable proactive troubleshooting. This reduces mean time to repair (MTTR) by up to 35% compared to legacy terminal boards.

Seamless Integration: Fully compatible with Mark VIe backplanes and GE’s Control System Toolbox software, the IS200TRPGHIBDD integrates effortlessly with other system components (e.g., IS220PAICH1B analog modules), supporting both new generator installations and retrofits of older GE control systems.

Application Areas

The GE IS200TRPGHIBDD is pivotal in power-centric industrial environments:

The GE IS200TRPGHIBDD is pivotal in power-centric industrial environments:

- Power Generation: Interfaces with gas/steam turbine generators to monitor stator current, rotor voltage, and breaker status, enabling precise load sharing and grid synchronization. Critical for compliance with NERC standards for grid stability.

- Renewable Energy: Connects to wind/solar farm generators, managing inverter output signals and ensuring smooth integration with utility grids.

- Industrial Power Systems: Manages backup generator signals in manufacturing plants, data centers, and hospitals, ensuring reliable standby power during grid outages.

- Oil & Gas: Supports generator sets in offshore platforms and refineries, monitoring fuel consumption and output to optimize efficiency and reduce emissions.

- Marine Propulsion: Links to shipboard generators, regulating power distribution to propulsion systems and auxiliary equipment, ensuring safe and efficient maritime operations.

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation preparation: Before installing the IS200TRPGHIBDD, ensure the Mark VIe backplane is powered off and properly grounded to prevent high-voltage damage. Verify compatibility with connected sensors (current transformers, voltage transducers) and use shielded, high-voltage-rated cables (16 AWG minimum) to minimize interference. Mount the board on a DIN rail or insulated panel using M4 screws, and secure DC-37 connectors to prevent vibration-induced disconnections. Configure signal ranges and alarm thresholds via GE’s Control System Toolbox.

Installation preparation: Before installing the IS200TRPGHIBDD, ensure the Mark VIe backplane is powered off and properly grounded to prevent high-voltage damage. Verify compatibility with connected sensors (current transformers, voltage transducers) and use shielded, high-voltage-rated cables (16 AWG minimum) to minimize interference. Mount the board on a DIN rail or insulated panel using M4 screws, and secure DC-37 connectors to prevent vibration-induced disconnections. Configure signal ranges and alarm thresholds via GE’s Control System Toolbox.

Maintenance recommendations: Inspect the IS200TRPGHIBDD quarterly for loose terminals, corrosion, and dust accumulation—pay special attention to high-voltage connections. Clean terminal blocks with a dry cloth to prevent signal degradation. Update associated firmware annually using GE’s software to access the latest diagnostic features. Replace the board immediately if LED fault indicators persist, as delayed replacement could compromise generator safety.

Product Warranty

GE provides a 1-year warranty for the IS200TRPGHIBDD, covering defects in materials and workmanship. This includes free replacement or repair, backed by a global network of certified technicians available 24/7 for critical support. Extended warranties (up to 5 years) and on-site calibration services are available for mission-critical generator applications. GE’s commitment to quality ensures the IS200TRPGHIBDD delivers reliable performance in even the most demanding power generation environments.

GE provides a 1-year warranty for the IS200TRPGHIBDD, covering defects in materials and workmanship. This includes free replacement or repair, backed by a global network of certified technicians available 24/7 for critical support. Extended warranties (up to 5 years) and on-site calibration services are available for mission-critical generator applications. GE’s commitment to quality ensures the IS200TRPGHIBDD delivers reliable performance in even the most demanding power generation environments.

HS:8471800000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com