Description

Product Overview

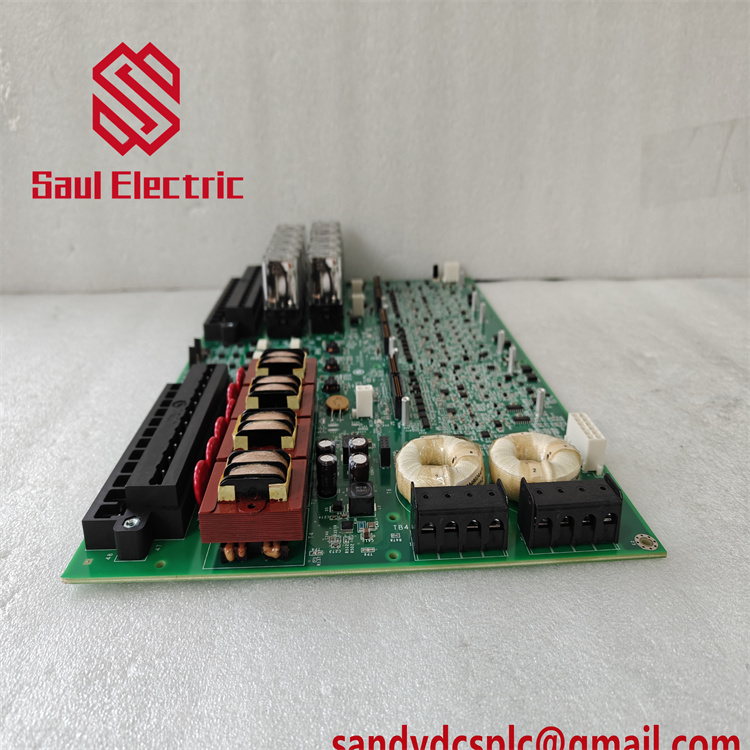

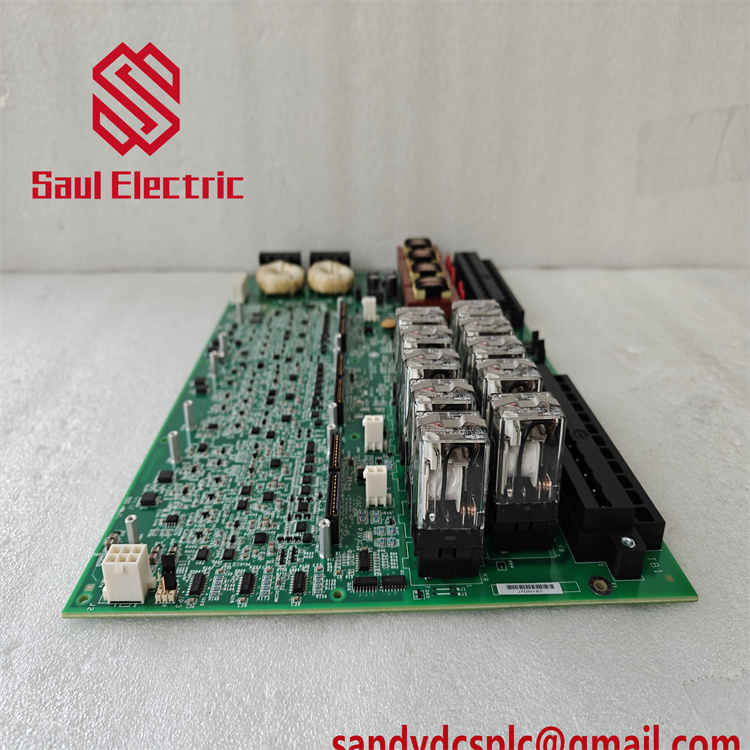

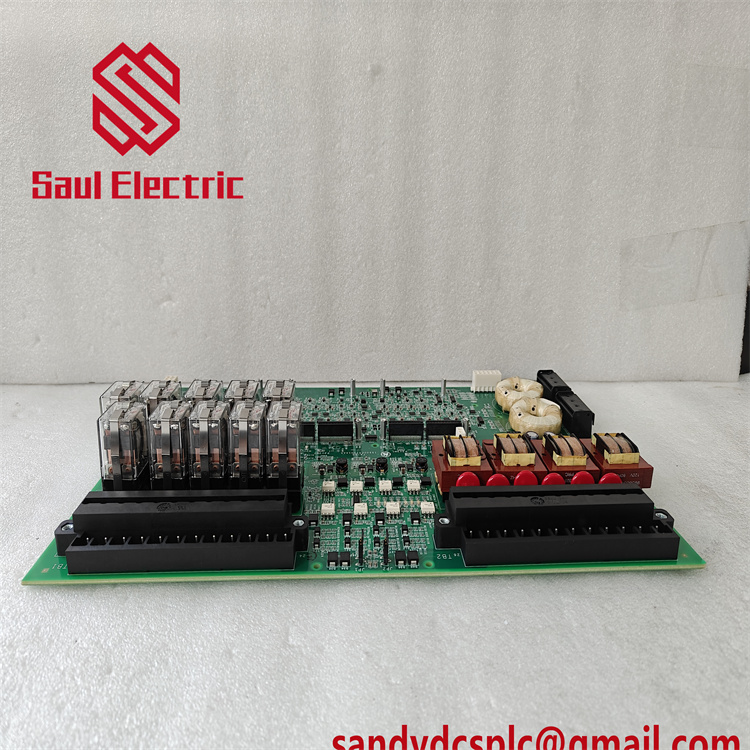

The GE IS200TDBTH2ACC is an advanced industrial control board engineered by General Electric for turbine management systems, particularly within GE’s Mark VI Speedtronic platform. Designed for critical applications in power generation, oil and gas, and heavy manufacturing, this module delivers high-precision control, robust environmental resilience, and seamless integration with industrial automation networks. Its core function is optimizing turbine performance through real-time data processing, fault diagnostics, and energy-efficient operation, ensuring reliability in extreme conditions (-40°C to +90°C) while adhering to global safety standards (CE, UL, FCC) .

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | IS200TDBTH2ACC |

| Type | Turbine Control Board |

| Operating Temp. | -40°C to +90°C (-40°F to +185°F) |

| Power Consumption | 50W |

| Processor | High-performance microprocessor |

| Memory | 1MB Flash, 64KB RAM (non-volatile for critical data retention) |

| I/O Channels | Configurable digital/analog interfaces |

| Comms Protocols | Modbus TCP, Ethernet/IP, RS-485, CANopen |

| Certifications | CE, UL, FCC |

| Dimensions | Compact aluminum alloy housing (standard 19″ rack-compatible) |

| Weight | ~0.75 kg (estimated) |

Key Features and Advantages

- High-Performance Control Architecture

- Equipped with a high-speed microprocessor and 1MB Flash memory, enabling rapid data processing for real-time turbine parameter adjustments (e.g., speed, temperature, pressure) .

- Supports Triple Modular Redundancy (TMR) configurations to eliminate single-point failures in safety-critical systems like power plant turbines .

- Extreme Environment Resilience

- Operates flawlessly in -40°C to +90°C ranges, with an aluminum alloy casing for superior heat dissipation and resistance to vibration (5G RMS), humidity, and dust (IP-rated) .

- Non-volatile memory retains operational data during power outages, minimizing restart downtime .

- Seamless Integration & Diagnostics

- Dual EtherNet/IP and Modbus TCP interfaces enable plug-and-play connectivity with Mark VI controllers, HMIs, and plant-wide DCS systems .

- Integrated diagnostic tools via GE’s ToolboxST software provide real-time alerts for faults (e.g., sensor drift, communication loss), reducing troubleshooting time by 40% .

- Energy Efficiency & Cost Optimization

- Reduces turbine energy consumption by dynamically adjusting control loops based on load demands, lowering operational costs by up to 15% .

- Hot-swappable design allows maintenance without system shutdowns, critical for industries like oil refineries or continuous-process manufacturing .

Application Areas

- Power Generation: Manages gas/steam turbine governors and exciters in SIL 2-rated safety systems, preventing overloads and overspeed events .

- Oil & Gas: Controls compressor stations and offshore drilling rig turbines, certified for hazardous areas (ATEX Zone 2) .

- Marine Propulsion: Monors thrust bearings and fuel systems in ship engines, meeting DNV-GL shock/vibration standards .

- Industrial Manufacturing: Optimizes high-inertia machinery (e.g., steel-rolling mills) via adaptive PID control loops .

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation & Maintenance

Installation:

- Mount vertically in Mark VI racks using VME64x backplane connectors.

- Use shielded cables (max 15 m) with ≥20 cm separation from high-voltage sources to prevent EMI .

- Validate firmware compatibility with ToolboxST v11.1+ .

Maintenance:

- Annual Calibration: Verify I/O accuracy with Fluke 744 calibrator.

- Component Replacement: Swap electrolytic capacitors after 60,000 operational hours (≈7 years).

- Firmware Updates: Apply patches via Ethernet with network redundancy enabled .

Product Assurance

GE provides a 12-month warranty covering defects. Global support includes 24/7 remote diagnostics and 48-hour on-site response for critical failures. Units undergo MIL-STD-810H environmental testing and 500-hour burn-in cycles, with MTBF exceeding 200,000 hours .

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com