Description

Product Overview

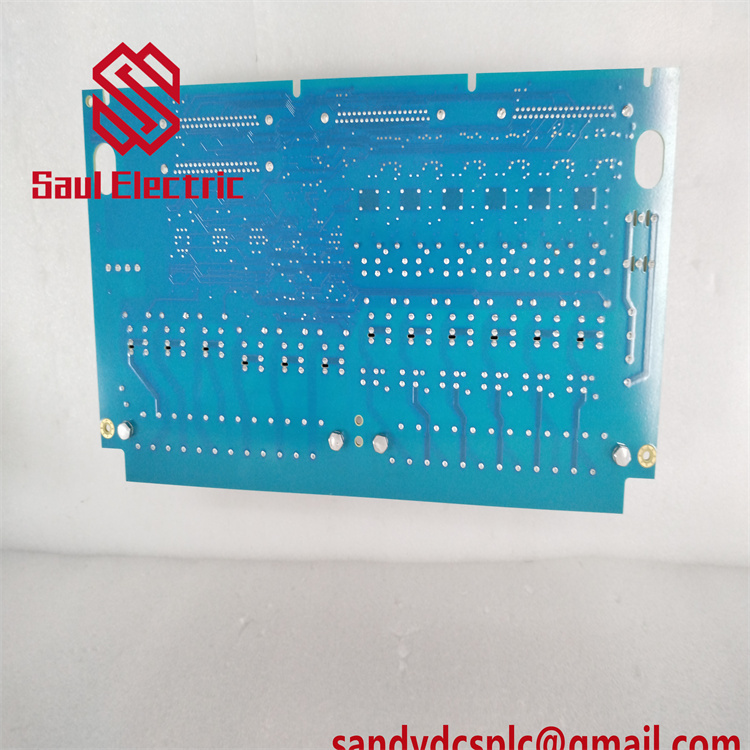

The GE IS200TBCIH2BCE is an advanced terminal board engineered by General Electric for high-reliability industrial control systems, specifically within the Mark VI Speedtronic series. Designed to manage 24 dry contact inputs, this module excels in environments demanding precision signal handling and robust noise suppression. Its group isolation technology prevents cross-talk between contacts, ensuring data integrity in complex automation setups like turbine control, power generation, and process manufacturing. The GE IS200TBCIH2BCE features a compact aluminum alloy chassis (33 cm × 10.2 cm × 4.8 cm), optimized for seamless integration into existing GE control platforms while withstanding harsh conditions (-20°C to +70°C). As a critical interface component, it enhances system reliability and reduces maintenance overhead, making it indispensable for industries prioritizing operational continuity and safety.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS200TBCIH2BCE |

| Manufacturer | GE (General Electric) |

| Product Type | Terminal Board |

| Input Capacity | 24 dry contacts |

| Isolation Type | Group isolation |

| Power Supply | 12 VDC |

| Power Consumption | <1 W |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions (L×W×H) | 33 cm × 10.2 cm × 4.8 cm |

| Weight | 0.54 kg |

| Connection Interface | Barrier-type terminal blocks |

| Noise Suppression | Integrated high-frequency surge protection |

Key Features and Benefits

Robust Signal Integrity: Group isolation separates contact inputs to eliminate signal interference, critical for high-noise environments like power plants and refineries. This ensures accurate data acquisition even during electrical surges.

Durability and Adaptability: The aluminum alloy construction provides exceptional resistance to vibration, corrosion, and temperature extremes. Compact dimensions facilitate installation in space-constrained control cabinets without compromising performance.

Operational Efficiency: Integrated noise suppression diodes/capacitors mitigate electromagnetic interference (EMI), reducing downtime caused by false triggers. Hot-swappable design allows maintenance without system shutdowns, optimizing productivity.

Application Areas

Energy Sector: Deployed in turbine control systems (e.g., gas/steam turbines) for real-time monitoring of safety interlocks and sensor inputs, enhancing grid stability.

Industrial Process Control: Integral to chemical plants and water treatment facilities, where it interfaces with pumps, valves, and alarms to ensure precise process automation and fault detection.

Manufacturing: Supports assembly line robotics and conveyor systems by relaying sensor data to PLCs, minimizing production disruptions through rapid signal processing.

Related Products

- IS200TBCIH1BBC: Similar terminal board with enhanced diagnostics for critical power applications.

- IS200TBCIH2C: I/O module with relay outputs (16 channels), ideal for actuator control.

- IS200EMIO1: Ethernet communication module, complements IS200TBCIH2BCE for network integration.

- IS200AIH001: Analog input module, expands system versatility for sensor-heavy environments.

- IS200DIB001: Digital input baseplate, suitable for high-speed switching applications.

Installation and Maintenance

Installation Preparation: Verify DC power stability (12 V±5%) and ground integrity before mounting. Use shielded cables for inputs to minimize EMI. Ensure ambient temperature stays within -20°C to +70°C for optimal IS200TBCIH2BCE performance.

Maintenance Recommendations: Quarterly inspections for dust accumulation and terminal tightness. Test isolation resistance annually using a megohmmeter. Replace immediately if physical damage or contact corrosion is detected.

Product Assurance

GE provides a 1-year warranty for the IS200TBCIH2BCE, covering manufacturing defects and component failures. Global technical support includes 24/7 troubleshooting and replacement part logistics. Compliance with CE/UL standards guarantees reliability in safety-critical applications, backed by GE’s legacy in industrial automation excellence.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com