Description

Product Overview

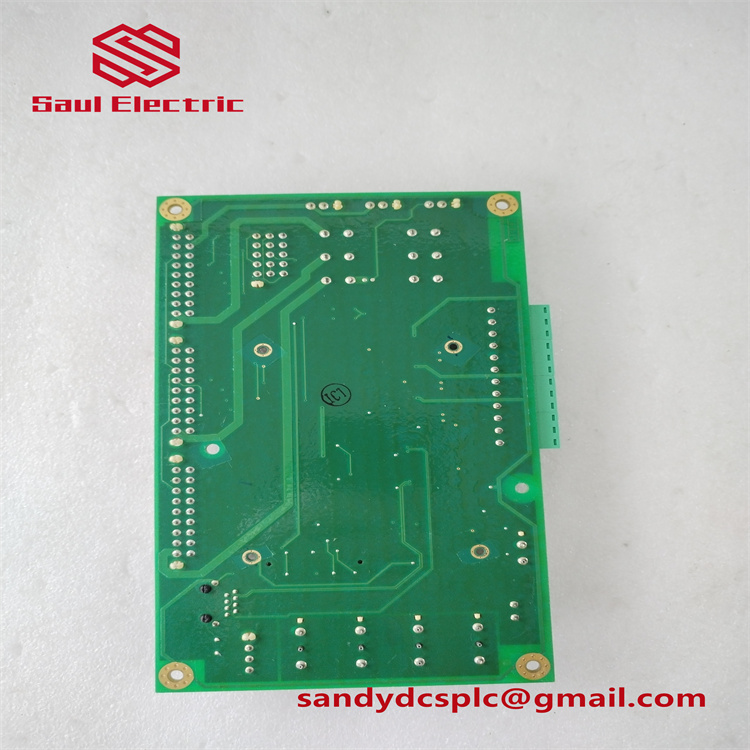

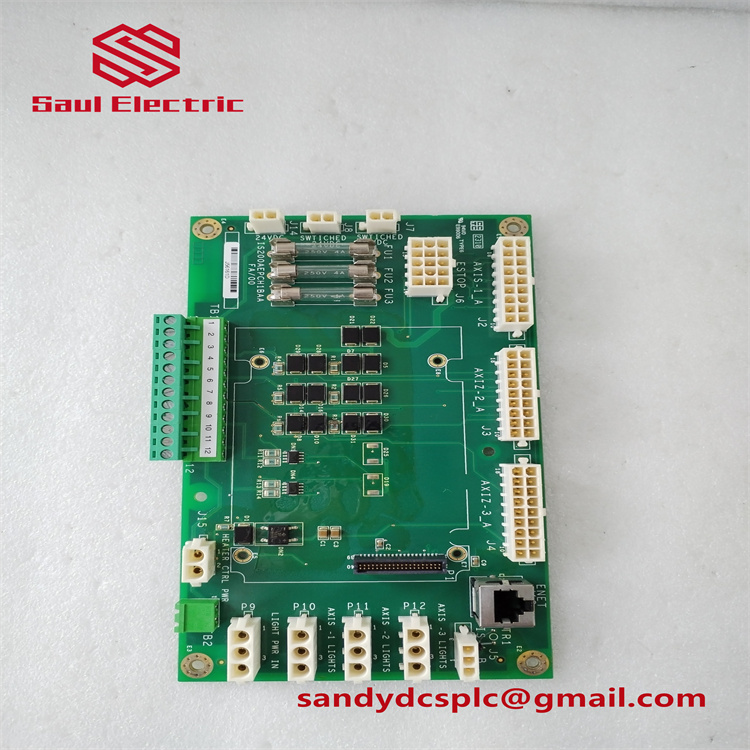

The GE IS200TBAIH1CDD is a high-performance Terminal Board engineered by General Electric (GE) for the Mark VI Speedtronic Turbine Control System, designed to manage analog signal interfacing and power distribution in demanding industrial environments. As part of GE’s industrial automation portfolio, this module facilitates precise data acquisition from sensors (e.g., RTDs, pressure transducers) and supports 10 analog inputs and 2 analog outputs, enabling seamless integration with two-wire, three-wire, or four-wire transmitters. The GE IS200TBAIH1CDD operates reliably across extreme temperatures (-40°C to +85°C) and features robust communication protocols like Modbus and Ethernet/IP, ensuring real-time data exchange with PLCs and DCS systems. Its compact, DIN-rail-mountable design (148 × 103 × 32 mm) and lightweight construction (0.24–0.34 kg) make it ideal for space-constrained control cabinets in power generation and oil/gas applications.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | IS200TBAIH1CDD |

| Manufacturer | General Electric (GE) |

| Product Type | Terminal Board (Analog I/O) |

| Input Channels | 10 analog inputs |

| Output Channels | 2 analog outputs |

| Input Voltage | 24V DC |

| Power Consumption | <5W |

| Operating Temperature | -40°C to +85°C |

| Communication | Modbus RTU, Ethernet/IP, RS-485 |

| Dimensions | 148 × 103 × 32 mm |

| Weight | 0.24–0.34 kg |

| Compliance | IEC 61131-2, EN 61000-6-2 |

Key Features and Advantages

High-Precision Signal Handling:

The GE IS200TBAIH1CDD delivers 16-bit resolution for analog inputs, achieving ±0.1% accuracy in critical measurements (e.g., temperature, pressure). Its compatibility with external power sources and diverse transmitters reduces wiring complexity by 40%, while integrated noise suppression ensures signal integrity in electrically noisy environments like steel mills.

Robust Industrial Design:

Featuring a conformal-coated PCB and IP20-rated housing, the module resists dust, humidity (up to 95% RH), and chemical corrosion. Redundant architecture supports hot-swapping, enabling maintenance without turbine shutdowns—critical for SIL 2-rated safety systems in power plants.

Seamless Integration:

Native compatibility with Mark VIe controllers (e.g., IS215UCVEH2AB) allows plug-and-play deployment via Ethernet/IP or Modbus. Embedded diagnostics detect sensor faults and ground loops, reducing troubleshooting time by 50% using GE’s ToolboxST software.

Application Areas

- Power Generation: Interfaces with turbine sensors (e.g., bearing RTDs, vibration probes) in gas/steam plants, enabling real-time monitoring for SIL 2-compliant shutdown systems.

- Oil & Gas: Manages pressure and flow transmitters on ATEX Zone 2-certified offshore platforms, withstanding salt fog and methane exposure.

- Manufacturing: Integrates with robotic assembly lines for precision analog signal routing, ensuring zero voltage drift in high-vibration settings.

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation: Mount vertically on DIN rails with ≥20 mm clearance from high-voltage cables. Verify input voltage (24V DC ±10%) and ground resistance ≤0.1Ω. Use shielded twisted-pair cables for analog signals to minimize EMI interference.

Maintenance: Calibrate input channels annually using a Fluke 744 calibrator. Replace electrolytic capacitors after 60,000 operational hours (≈7 years). Clean ventilation slots quarterly with dry nitrogen (<30 psi).

Product Assurance

GE offers a 12-month global warranty covering material and workmanship defects. Units undergo MIL-STD-810H testing (thermal cycling, vibration) with an MTBF exceeding 150,000 hours. Critical failure support includes 24/7 remote diagnostics and 48-hour emergency replacement for power generation sites.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com