Description

Product Overview

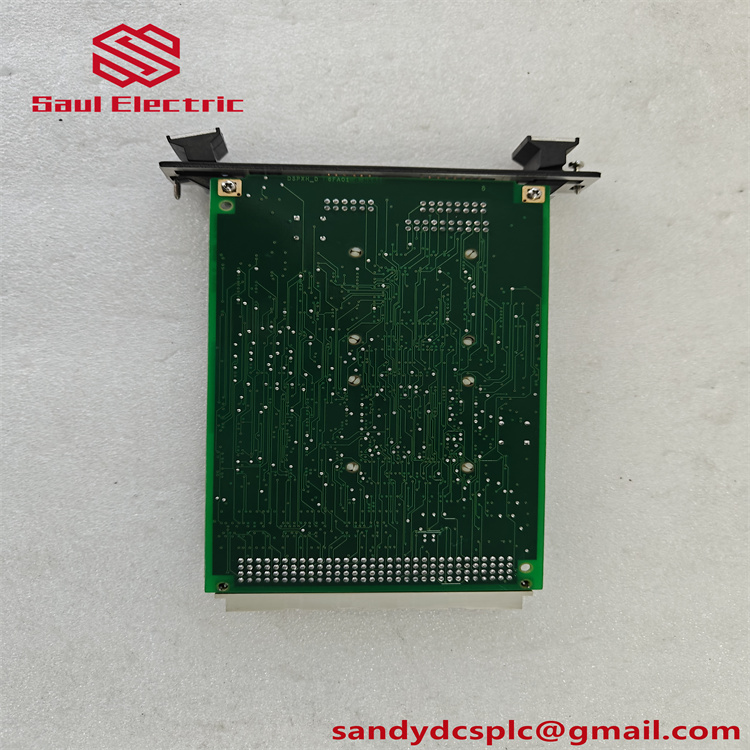

The GE IS200STAIH1ABB is a high-precision Analog Input/Output Terminal Board engineered for GE’s Mark VI Speedtronic Turbine Control Systems. Designed for industrial automation, this module provides critical signal conditioning and processing for sensors monitoring temperature, pressure, flow, and vibration in power generation and heavy machinery applications. With 10 analog inputs and 2 analog outputs, the GE IS200STAIH1ABB supports 2-wire, 3-wire, and 4-wire transmitters, delivering ±0.05% signal accuracy via 16-bit ADC conversion. Its robust DIN-rail-mountable design integrates seamlessly into distributed control architectures, ensuring real-time data reliability for safety-critical operations like turbine speed regulation and emergency shutdowns (SIL 2 certified). Featuring conformal-coated PCBs and extended temperature resilience (-40°C to +85°C), this module excels in harsh environments such as coal plants, offshore platforms, and chemical processing facilities, where EMI resistance and vibration tolerance (5G RMS) are paramount .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200STAIH1ABB |

| Manufacturer | General Electric (GE) |

| Product Type | Analog I/O Terminal Board |

| Input Channels | 10 (configurable for ±10V DC, 4–20mA, RTD, thermocouple) |

| Output Channels | 2 (analog, 4–20mA/0–10V DC) |

| Accuracy | ±0.05% Full Scale |

| Isolation Voltage | 1,500V AC (channel-to-system) |

| Operating Temperature | -40°C to +85°C |

| Power Supply | 24V DC (±10%) |

| Communication | Backplane integration with Mark VI controllers (Ethernet/Profibus) |

| Dimensions | 188 × 106 × 35 mm (L×W×H) |

| Weight | 0.75 kg |

| Certifications | CE, UL, cUL, SIL 2 (IEC 61508) |

Key Features and Advantages

Precision Signal Conditioning:

The GE IS200STAIH1ABB utilizes dual 16-bit ADCs with auto-calibration and hardware linearization, maintaining ±0.05% accuracy across extreme temperatures. Integrated Cold Junction Compensation (CJC) corrects thermocouple drift in fluctuating ambient conditions, critical for turbine bearing monitoring .

Industrial Durability:

Featuring gold-plated connectors, conformal-coated PCBs, and IP20-rated enclosure (upgradable to IP52), the module resists humidity, dust, and chemical corrosion. Vibration tolerance (5G RMS) ensures stability in coal mills or compressor stations .

Seamless System Integration:

Hot-swappable DIN-rail mounting allows replacements without turbine shutdown. Native compatibility with Mark VI controllers (e.g., IS215UCVEH2AB) and I/O packs (e.g., IS220YAICS1A) simplifies retrofitting into legacy systems .

Advanced Diagnostics:

Onboard LED fault indicators and ToolboxST software provide real-time alerts for signal loss or sensor drift, reducing troubleshooting time by 40% and preventing unplanned downtime .

Application Areas

- Power Generation: Monitors steam pressure/temperature in turbine inlet valves for SIL 2-rated emergency shutdown systems .

- Oil & Gas: Conditions signals from wellhead pressure transmitters in offshore platforms (ATEX Zone 2 compliant with terminal boards) .

- Water Treatment: Processes flowmeter and pH sensor data for reactor control in chemical plants .

- Marine Propulsion: Tracks exhaust temperatures in ship engines, certified for DNV-GL shock/vibration standards .

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation: Mount vertically on DIN rail using VME64x backplane connectors. Use shielded twisted-pair cables (<15 m) routed ≥20 cm from AC power sources. Pair with IS200STAP1 for fused signal input .

Maintenance: Calibrate I/O channels annually with Fluke 744 calibrator. Replace electrolytic capacitors after 50,000 operational hours (≈5.7 years). For firmware updates, use ToolboxST v11.1+ with network redundancy enabled .

Product Assurance

GE offers a 24-month global warranty covering material and workmanship defects. Critical failure support includes 24/7 remote diagnostics via GE Digital Support Hub and 48-hour on-site response for power generation sites. Modules undergo MIL-STD-810H environmental testing and 500-hour burn-in cycles .

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com