Description

Product Overview

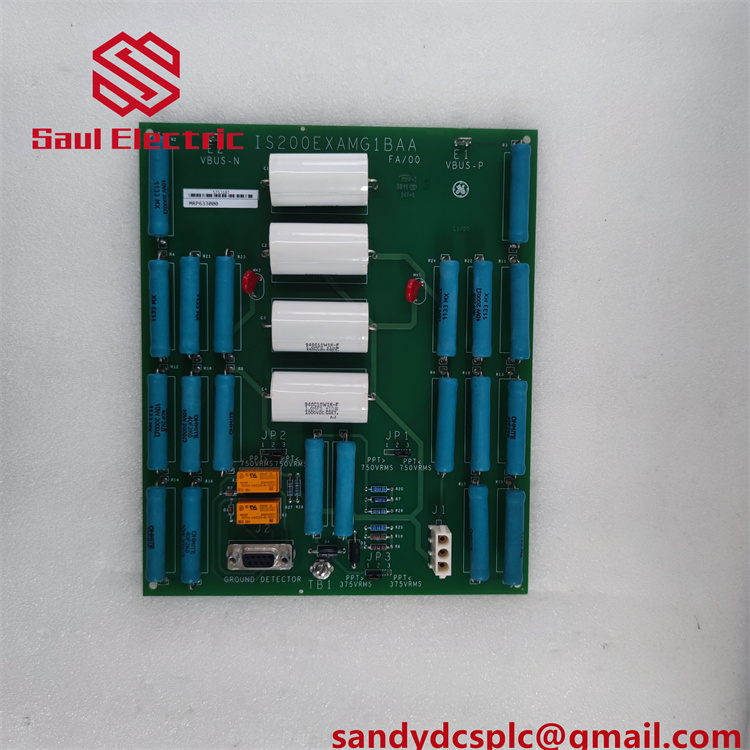

The GE IS200SRTDH2ABA is a high-performance Resistance Temperature Detector (RTD) Terminal Board designed for GE’s Mark VIe turbine control system, a cornerstone of industrial automation in power generation, oil & gas, and heavy machinery. As a critical interface between RTD sensors and control systems, the IS200SRTDH2ABA ensures precise temperature monitoring for mission-critical applications. Built on the legacy of the IS200SRTDH2A, this revision incorporates advanced signal conditioning and diagnostic capabilities to meet the demands of modern industrial environments.

The GE IS200SRTDH2ABA is a high-performance Resistance Temperature Detector (RTD) Terminal Board designed for GE’s Mark VIe turbine control system, a cornerstone of industrial automation in power generation, oil & gas, and heavy machinery. As a critical interface between RTD sensors and control systems, the IS200SRTDH2ABA ensures precise temperature monitoring for mission-critical applications. Built on the legacy of the IS200SRTDH2A, this revision incorporates advanced signal conditioning and diagnostic capabilities to meet the demands of modern industrial environments.

Engineered for seamless integration with GE’s Mark VIe backplanes, the IS200SRTDH2ABA supports 8 isolated RTD channels compatible with 2/3/4-wire configurations (PT100, PT500, Ni100). Its 36-terminal design (18 per block) allows for flexible wiring in complex systems, while the DC-37 pin connector ensures robust connectivity. The board’s conformal-coated PCB and -30°C to +65°C operating range make it suitable for harsh conditions, from high-vibration turbine halls to corrosive chemical plants.

Key to its functionality is the IS200SRTDH2ABA’s ability to compensate for lead resistance (up to 100Ω) and filter noise (0.1/1/10Hz), ensuring measurement accuracy within ±0.1°C across a wide temperature range (-200°C to +850°C). This precision is vital for applications like turbine inlet temperature control, where even minor deviations can impact efficiency and safety. The board’s diagnostic features—including open-circuit detection and real-time sensor health monitoring—enable proactive maintenance, reducing downtime by up to 30% compared to legacy systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200SRTDH2ABA |

| Manufacturer | General Electric (GE) |

| Product Type | RTD Terminal Board |

| Series | Mark VIe |

| Number of Channels | 8 (isolated) |

| Supported RTD Types | PT100, PT500, Ni100 (2/3/4-wire configurable) |

| Terminal Count | 36 (18 per block) |

| Connector Type | DC-37 pin (female) |

| Lead Resistance Compensation | Up to 100Ω |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 263 mm x 58 mm x 28 mm (10.35″ x 2.28″ x 1.10″) |

| Weight | ~0.3 kg |

| Certifications | UL 508, CE, CSA |

Main Features and Advantages

Enhanced Signal Conditioning: The IS200SRTDH2ABA employs advanced analog circuitry to minimize noise and drift, critical for high-precision temperature measurements in environments with electromagnetic interference. Its 16-bit resolution (upgraded from 15-bit in earlier revisions) ensures ±0.1°C accuracy, making it ideal for monitoring turbine exhaust temperatures or chemical reactor processes.

Enhanced Signal Conditioning: The IS200SRTDH2ABA employs advanced analog circuitry to minimize noise and drift, critical for high-precision temperature measurements in environments with electromagnetic interference. Its 16-bit resolution (upgraded from 15-bit in earlier revisions) ensures ±0.1°C accuracy, making it ideal for monitoring turbine exhaust temperatures or chemical reactor processes.

Intelligent Diagnostics: Real-time alerts for open circuits, short circuits, and sensor drift enable predictive maintenance. LED indicators for power, channel status, and fault conditions provide at-a-glance system health, reducing troubleshooting time. The board’s self-diagnostic firmware also logs historical data for trend analysis, optimizing maintenance schedules.

Hazardous Environment Readiness: With IP20-rated conformal coating, the IS200SRTDH2ABA resists dust, moisture, and vibration, ensuring reliability in extreme conditions. While not ATEX-certified, it meets UL 508 and CE standards for industrial safety, making it suitable for non-hazardous zones in oil refineries, power plants, and manufacturing facilities.

Flexible Integration: The IS200SRTDH2ABA interfaces seamlessly with GE’s IS220PRTDH1A RTD Input Module, forming a complete temperature monitoring solution. Its DIN-rail mounting allows easy retrofitting into existing control panels, while compatibility with GE’s Control System Toolbox simplifies configuration and firmware updates.

Application Areas

The GE IS200SRTDH2ABA excels in temperature-critical industrial processes:

The GE IS200SRTDH2ABA excels in temperature-critical industrial processes:

- Power Generation: Monitors turbine inlet/outlet temperatures, generator winding heat, and boiler tube integrity to optimize efficiency and prevent overheating.

- Oil & Gas: Tracks reactor temperatures in refineries, compressor intercooler performance, and wellhead fluid heat to ensure safe and efficient extraction.

- Chemical Processing: Controls batch reactor temperatures with precision, ensuring product quality in pharmaceutical and specialty chemical production.

- Manufacturing: Maintains consistent furnace temperatures in steel mills, plastic extrusion lines, and glass production, minimizing defects.

- Renewable Energy: Regulates heat in solar thermal plants and wind turbine gearboxes, maximizing energy output while protecting equipment from thermal stress.

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation Preparation: Ensure the Mark VIe backplane is powered off and grounded. Verify RTD compatibility (2/3/4-wire) and use shielded twisted-pair cables to minimize noise. Mount the IS200SRTDH2ABA on a DIN rail or flat surface, securing it with M4 screws. Configure via GE’s Control System Toolbox, setting filter rates and temperature ranges for specific applications.

Installation Preparation: Ensure the Mark VIe backplane is powered off and grounded. Verify RTD compatibility (2/3/4-wire) and use shielded twisted-pair cables to minimize noise. Mount the IS200SRTDH2ABA on a DIN rail or flat surface, securing it with M4 screws. Configure via GE’s Control System Toolbox, setting filter rates and temperature ranges for specific applications.

Maintenance Recommendations: Inspect quarterly for loose connections and dust accumulation. Calibrate annually using GE-certified standards to maintain ±0.1°C precision. Monitor LED indicators for fault alerts and update firmware to access new diagnostic features. Replace aging RTD sensors if drift exceeds 0.5°C to ensure reliable data.

Product Warranty

GE provides a 1-year warranty for the IS200SRTDH2ABA, covering defects in materials and workmanship. This includes free replacement/repair and 24/7 technical support via phone, email, or GE’s online portal. Extended warranties (up to 5 years) and on-site calibration services are available for mission-critical applications. GE’s global network of certified technicians ensures rapid support, reinforcing confidence in the IS200SRTDH2ABA’s performance in demanding environments.

GE provides a 1-year warranty for the IS200SRTDH2ABA, covering defects in materials and workmanship. This includes free replacement/repair and 24/7 technical support via phone, email, or GE’s online portal. Extended warranties (up to 5 years) and on-site calibration services are available for mission-critical applications. GE’s global network of certified technicians ensures rapid support, reinforcing confidence in the IS200SRTDH2ABA’s performance in demanding environments.

HS:8471800000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com