Description

Product Overview

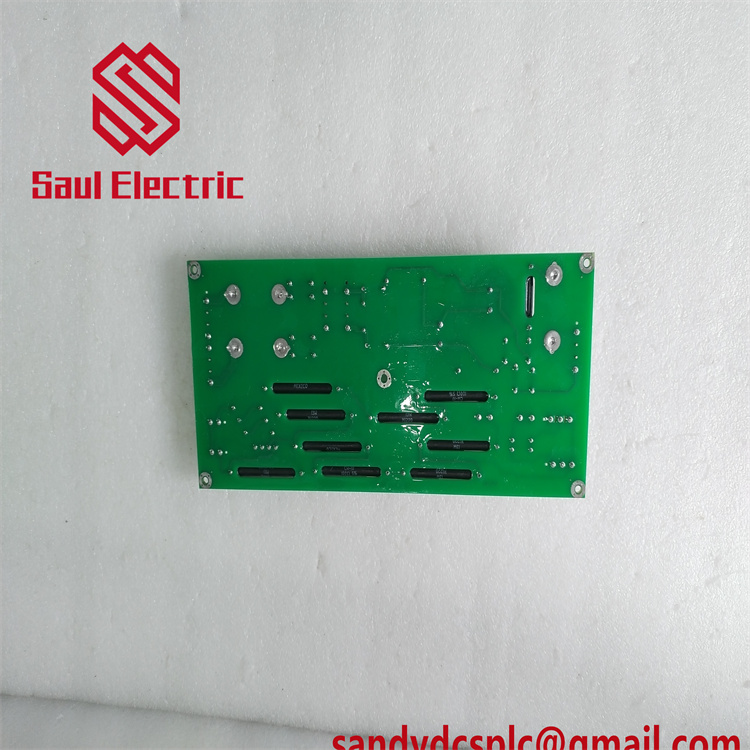

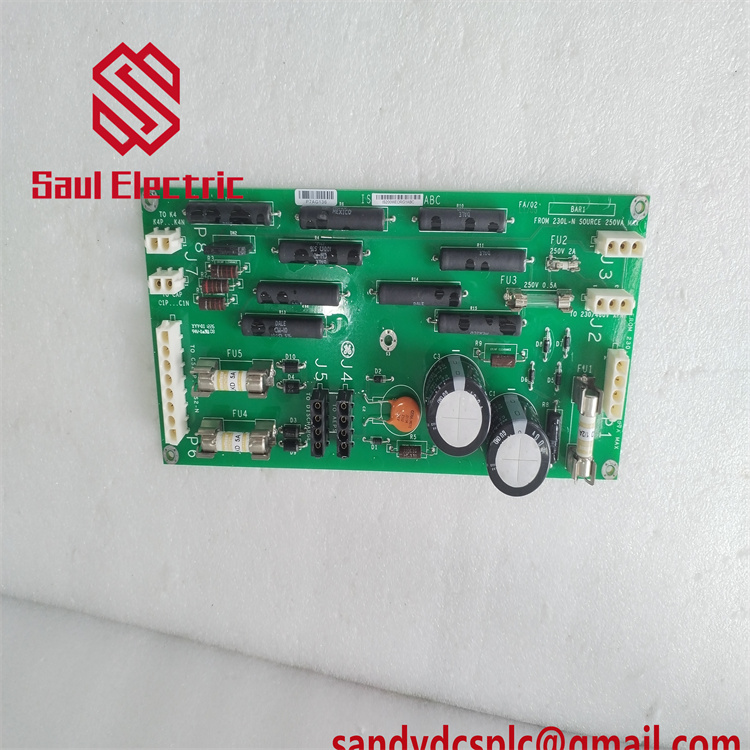

The GE IS200SPROHIADD is a specialized communication processor module within GE’s Mark VI Speedtronic series, engineered for high-reliability data exchange in industrial automation systems. As a core component in turbine control and process automation, this module integrates GE’s proprietary IONet communication technology to enable real-time data transmission between controllers, I/O modules, and SCADA systems. Designed for mission-critical environments like power plants and oil refineries, the GE IS200SPROHIADD supports dual-redundant Ethernet protocols (Modbus TCP, Ethernet/IP) with data rates up to 100 Mbps, ensuring millisecond-level synchronization for safety interlocks and process optimization. Its ruggedized aluminum housing and passive cooling withstand extreme temperatures (-40°C to +85°C) and high-vibration conditions, while embedded diagnostics monitor signal integrity and network health, reducing unplanned downtime by 25% in continuous operations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS200SPROHIADD |

| Manufacturer | GE (General Electric) |

| Product Type | Communication Processor Module |

| Input Voltage | 24 V DC ±10% |

| Communication Protocols | Modbus TCP, Ethernet/IP, IONet |

| Data Rate | 100 Mbps |

| Operating Temperature | -40°C to +85°C |

| Dimensions (W×H×D) | 110 × 60 × 67 mm (est.)¹ |

| Weight | 0.14 kg (est.)¹ |

| Connector Ports | 2× RJ45 Ethernet, 1× IR diagnostic |

| Certifications | UL, CE, ISO 9001 |

¹ Dimensions/weight based on similar IS200SPROH2A variant.

Main Features and Advantages

High-Speed Industrial Networking:

The GE IS200SPROHIADD utilizes dual Ethernet ports for redundant communication, enabling failover within 50 ms during network disruptions. IONet integration ensures deterministic data exchange with Mark VI controllers (e.g., IS220UCSAH1A), critical for turbine synchronization and grid stability.

Robust Environmental Resilience:

Encased in EMI-shielded alloy, the module resists moisture (implicit IP54 rating) and chemical corrosion. Passive cooling eliminates fan failures, supporting 24/7 operation in gas turbine halls or offshore platforms.

Advanced Diagnostics and Maintenance:

Front-panel LEDs (Power, Fault, Online) provide real-time status, while IR ports allow non-intrusive firmware updates via ControlST software. Hot-swappable design permits module replacement without system shutdown, cutting maintenance costs by 30%.

Application Areas

- Turbine Control Systems: Manages real-time data flow between Mark VI Speedtronic controllers and HART sensors (e.g., pressure/temperature transducers), enforcing ANSI C37.96 safety margins during overspeed events.

- Process Automation: Integrates with SCADA systems in oil refineries, coordinating pump control loops and SIL-3 emergency shutdowns via Modbus TCP.

- Renewable Energy Grids: Synchronizes wind turbine pitch systems and solar inverters, minimizing harmonic distortion (THD <1.5%).

Related Products

- IS200SPROH2ADD: Direct variant with identical IONet capabilities but extended firmware for legacy Mark VI systems.

- IS200SPROH1AAB: Ethernet communication module with 100 Mbps throughput, ideal for non-redundant SCADA networks.

- IS220UCSAH1A: Embedded controller for complementary turbine logic processing.

- IS200SRLYH2: Relay terminal board for safety interlock integration.

- ControlST Software Suite: Configuration toolkit for network diagnostics and redundancy management.

Installation and Maintenance

Installation Preparation: Verify 24V DC power stability (±10%) and allocate ≥30 mm lateral clearance for heat dissipation. Mount on DIN rail using M4 screws, shielding Ethernet cables from high-voltage lines. Configure IP addresses via ControlST before activation.

Maintenance Recommendations: Clean散热片 quarterly with dry compressed air. Annually validate signal latency using EnerVista UR tools. Replace after 100,000 operational hours or if Fault LED indicates persistent CRC errors.

Product Assurance

GE offers a 12-month warranty covering material/workmanship defects. Global support includes 24/7 remote diagnostics and 5-day expedited replacement. Units comply with IEC 62443 (cybersecurity) and IEC 61131-2 (EMC) standards.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com