Description

Product Overview

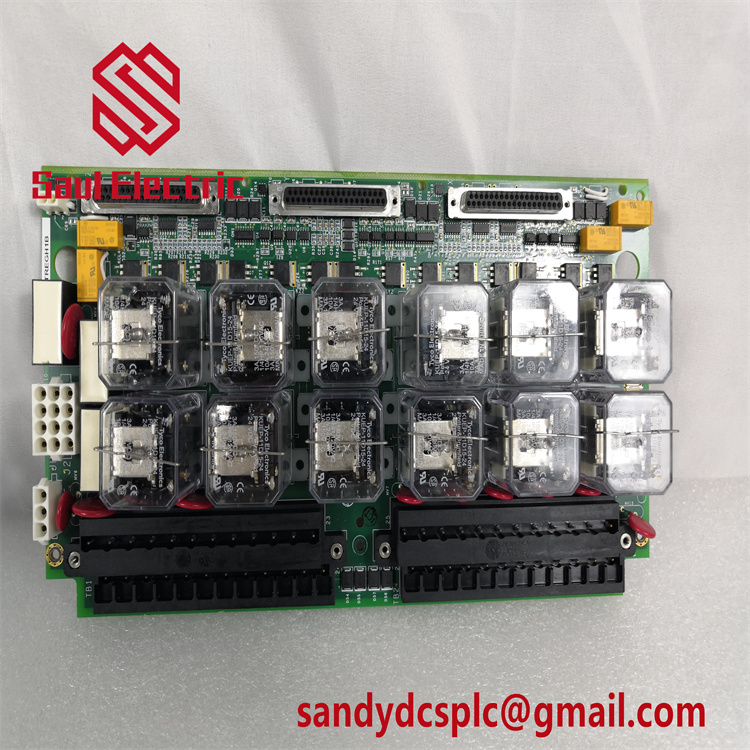

The GE IS200SHRAS1A is a high-performance HART-enabled analog input/output terminal board designed for GE’s Mark VIe control platform, serving as a critical interface between smart field devices and industrial control systems. This module integrates advanced signal conditioning with bidirectional communication capabilities, making it essential for applications requiring precise process monitoring and diagnostics.

The GE IS200SHRAS1A is a high-performance HART-enabled analog input/output terminal board designed for GE’s Mark VIe control platform, serving as a critical interface between smart field devices and industrial control systems. This module integrates advanced signal conditioning with bidirectional communication capabilities, making it essential for applications requiring precise process monitoring and diagnostics.

As a key component of GE’s safety-focused automation solutions, the GE IS200SHRAS1A supports 8 isolated analog inputs (4-20 mA/±10 V DC) and 2 analog outputs (4-20 mA), enabling seamless integration with pressure transmitters, temperature sensors, and control valves. Its HART 7 protocol compatibility allows real-time access to device health data, calibration status, and process variables, enhancing predictive maintenance capabilities. The GE IS200SHRAS1A is engineered for rugged industrial environments, with a compact design that fits seamlessly into Mark VIe racks, ensuring scalability in both small-scale machines and large distributed systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200SHRAS1A |

| Manufacturer | General Electric (GE) |

| Product Type | HART-Enabled Analog I/O Terminal Board |

| Input Channels | 8 isolated (4-20 mA / ±10 V DC) |

| Output Channels | 2 isolated (4-20 mA) |

| Communication Protocols | HART 7, IS Bus, PROFIBUS-DP |

| Power Supply | 24 V DC ±10% |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 159 mm (height) × 178 mm (width) × 80 mm (depth) |

| Weight | 0.85 kg |

| Isolation Voltage | 1,500 V DC |

| Compliance | IEC 61508 (SIL 3), IEC 60068-2-6 |

Main Features and Advantages

HART-enabled smart diagnostics: The GE IS200SHRAS1A facilitates bidirectional communication with HART 7 devices, allowing remote configuration, calibration, and real-time monitoring of sensor health. This eliminates the need for manual field checks, reducing downtime and maintenance costs.

Isolated signal integrity: Each input/output channel is electrically isolated to prevent cross-talk and ground loops, ensuring accurate signal transmission even in high-noise industrial environments. This is critical for maintaining precision in applications like turbine control and chemical batch processing.

Rugged industrial design: With conformal coating and robust terminal blocks, the GE IS200SHRAS1A withstands extreme temperatures, vibration, and moisture, making it suitable for offshore platforms, mining operations, and other harsh settings. Its fail-safe architecture ensures outputs default to a safe state during power disruptions.

Seamless integration: The module hot-swaps into Mark VIe racks without system shutdown, supporting easy scalability. It pairs with GE’s IS Bus for high-speed data exchange, ensuring compatibility with existing Mark VIe controllers and third-party systems.

Application Areas

In power generation, the GE IS200SHRAS1A monitors turbine inlet temperatures, steam pressure, and fuel flow rates, providing critical data for optimizing efficiency and preventing overheating. Its HART capabilities enable remote diagnostics of transmitters in hard-to-reach turbine enclosures.

Within the oil & gas industry, the module manages subsea chemical injection systems and wellhead pressure sensors, leveraging HART data to predict sensor drift and schedule maintenance before failures occur. Its wide temperature range makes it ideal for offshore platforms and subsea manifolds.

In chemical processing, the GE IS200SHRAS1A controls reactor pH levels and flow rates, ensuring regulatory compliance by maintaining precise analog signal integrity. It integrates with smart valves to adjust process parameters in real time, reducing waste and improving batch consistency.

Water treatment plants use the module to monitor dissolved oxygen levels and control dosing pumps, with HART diagnostics alerting operators to sensor fouling or calibration issues before process upsets occur.

Related Products

IS200TBAIH1CDD – Analog Input Terminal Board

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

Installation and Maintenance

Installation preparation: Before installing the GE IS200SHRAS1A, ensure the Mark VIe rack is powered off and properly grounded. Align the module with the backplane connectors, securing it with captive screws (4.5 N·m torque). Use anti-static equipment to prevent damage, and verify wiring polarity for analog signals—mixing current/voltage inputs may cause inaccuracies.

Maintenance recommendations: Inspect terminal blocks quarterly for loose connections and clean dust from vents to maintain cooling. Replace the internal battery (CR2032) every 5 years to preserve configuration data. Use a HART communicator to test channel integrity annually, and update firmware periodically to ensure compatibility with new HART device models.

Product Warranty

The GE IS200SHRAS1A is backed by a 2-year warranty covering defects in materials and workmanship. Technical support is available 24/7, with remote diagnostics and on-site assistance from certified engineers. A global network of spare parts ensures rapid replacement if needed, minimizing downtime and ensuring continuous operation of critical systems.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com