Description

Product Overview

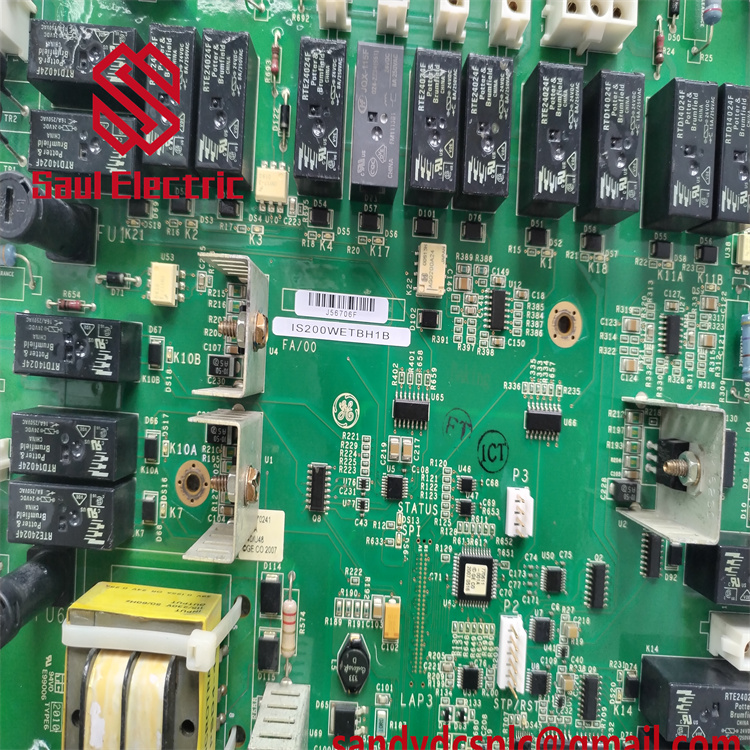

The GE IS200SHRAH2ABC is a high-precision HART-enabled analog input/output terminal board designed by General Electric for the Mark VI/Mark VIe industrial control systems. As a critical component in turbine management and process automation, this module facilitates bidirectional communication with HART-compliant field devices (e.g., pressure transmitters, temperature sensors), converting analog signals (1–5V DC) into digital data for real-time monitoring and control. Engineered for harsh environments, its compact, fanless design (IP20-rated) ensures reliable operation across temperatures from -20°C to +60°C, supporting 12 independent channels with ≤15Ω sensor lead resistance and 800Ω output loads. The GE IS200SHRAH2ABC integrates seamlessly with GE’s Speedtronic platforms, enhancing predictive maintenance and system stability in power generation, oil refineries, and chemical processing plants.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS200SHRAH2ABC |

| Manufacturer | GE (General Electric) |

| Product Type | HART Analog I/O Terminal Board |

| Channels | 12 |

| Input Range | 1–5V DC |

| Max Sensor Lead Resistance | 15 Ω |

| Output Load | 800 Ω |

| Communication Protocol | HART + RS-485 |

| Isolation Voltage | 2500V RMS |

| Power Consumption | ≤5W |

| Operating Temperature | -20°C to +60°C |

| Dimensions (W×H×D) | 100×80×20 mm (est.) |

| Weight | 0.5 kg |

| Certifications | CE, SIL 2/3 (safety-critical) |

Note: Dimensions inferred from similar IS200SHRAH2ACC model.

Main Features and Advantages

HART Protocol Integration:

The GE IS200SHRAH2ABC supports HART digital signal superposition on 4–20mA analog loops, enabling simultaneous data transmission from smart sensors (e.g., valve position diagnostics, sensor health) without additional wiring. This reduces commissioning time by 30% and enables predictive maintenance.

High Signal Integrity:

EMI-shielded circuitry and 2500V isolation prevent noise interference in electrically noisy environments (e.g., turbine halls). Precision signal conditioning (±0.1% accuracy) ensures reliable data for critical processes like compressor surge control or boiler pressure regulation.

Modular Redundancy:

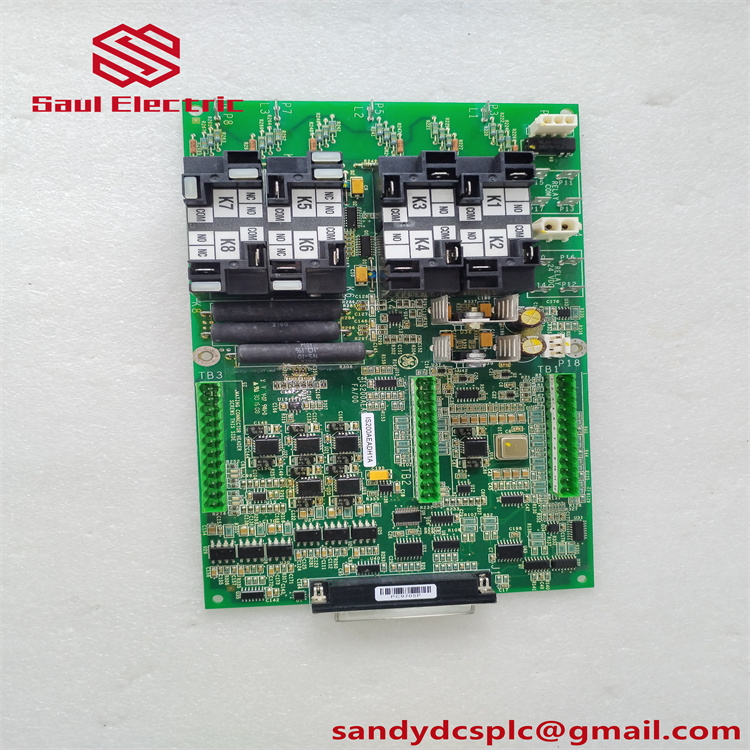

Hot-swappable design allows replacement without system shutdown. Dual-redundant configurations sync parameters automatically via ControlST software, minimizing downtime in 24/7 operations like power grid synchronization.

Application Areas

- Turbine Control Systems: Interfaces with HART sensors in GE Speedtronic turbines, monitoring bearing temperatures and vibration thresholds to prevent overspeed failures.

- Oil & Gas Refineries: Acquires pressure/flow data from transmitters in distillation columns, enabling real-time leak detection and SIL 3-rated emergency shutdowns.

- Chemical Processing: Controls reactor vessel temperatures via HART-enabled actuators, ensuring stoichiometric precision in batch processes.

Related Products

- IS200SHRAH2ACC: Identical to IS200SHRAH2ABC but with extended firmware for legacy Mark VI systems.

- IS200SHRAS2A: SIL 3-certified variant for nuclear safety applications.

- IS220PAICH2A: Complementary analog input module for temperature/pressure monitoring.

- DS200KLDBG1ABC: Excitation control card for generator synchronization.

- IC695CPU315: Redundant processor for high-availability PLC systems.

Installation and Maintenance

Installation Preparation: Verify DIN rail space and 24V DC power (18–32V range). Route shielded cables away from high-voltage lines; ground terminals to 0.6 N·m torque. Configure HART addressing via ControlST software before power-up.

Maintenance Recommendations: Clean vents quarterly with dry air. Annually calibrate channels using GE DriveTool and inspect for loose BNC connectors. Replace after 100,000 operational hours or if diagnostic LEDs indicate signal drift.

Product Assurance

GE provides a 12-month warranty covering material defects. Global support includes 24/7 remote diagnostics and 5-day replacement for critical failures. Units comply with IEC 61508 (functional safety) and IEC 61326 (EMC) standards.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com