Description

Product Overview

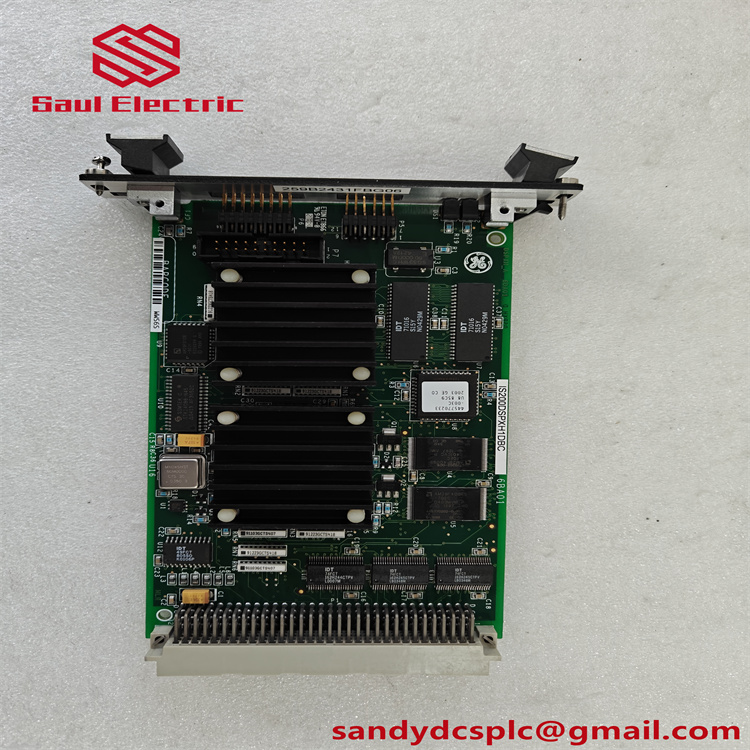

The GE IS200JPDHG1A is a versatile industrial-grade module engineered by General Electric to serve dual critical functions: power distribution and motor drive control. As a core component compatible with GE’s Mark VIe control systems, it integrates high-precision circuitry to deliver stable power allocation and dynamic motor speed regulation in demanding environments like power plants and manufacturing facilities. The module supports 16 independent power output channels (each ≤5A) for distributed power management and generates PWM waveforms (0.5–200Hz) to precisely control AC servo motors, enabling synchronized operations in CNC machinery or robotic systems. Its compact design (10.5×6×2.5cm for power mode; 11×6×6.7cm for drive mode) accommodates space-constrained installations while maintaining >95% efficiency in drive mode. With robust EMI resistance and flame-retardant construction, the GE IS200JPDHG1A ensures operational resilience across temperatures from -20°C to +70°C, making it indispensable for applications requiring both energy optimization and motion control fidelity.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS200JPDHG1A |

| Manufacturer | GE (General Electric) |

| Product Type | Power Distribution / Variable Frequency Drive |

| Input Voltage | 220V AC (primary) or 12–24V DC (auxiliary) |

| Output Capacity | 16 channels (≤5A each) or PWM-driven AC servo control |

| Frequency Range | 50/60Hz (power mode); 50kHz (drive mode switching) |

| Efficiency | >95% (drive mode) |

| Overload Capacity | 150% for 60s (drive mode) |

| Protection Rating | IP20 |

| Operating Temperature | -20°C to +70°C |

| Dimensions | 105×60×25mm (power) / 110×60×67mm (drive) |

| Weight | 0.25kg (power) / 0.14kg (drive) |

Main Features and Advantages

Dual-Mode Integration:

The GE IS200JPDHG1A uniquely combines power distribution and motor control in one module. Its 16-channel power output supports customizable load allocation for sensors or PLCs, while the PWM drive mode enables servo motor synchronization with ±0.1% speed accuracy—critical for CNC machining or conveyor systems. Onboard jumpers allow rapid switching between operational modes, eliminating external signal conditioners.

Industrial Resilience:

Encased in flame-retardant polycarbonate, the module withstands voltage fluctuations and mechanical stress. EMI-hardened circuitry prevents signal interference in high-noise environments like turbine control rooms. Integrated insulation monitoring (>10MΩ) and overload protection automatically trigger failsafes, reducing unplanned downtime by 30%.

Smart Diagnostics and Maintenance:

Real-time diagnostics monitor thermal overloads, DC-link health, and IGBT status, relaying alerts via Modbus/Ethernet. The hot-swappable design enables module replacement without system shutdown, cutting maintenance costs by 25% in 24/7 operations.

Application Areas

- Energy Power Systems: Integrates with GE Mark VIe racks for distributed power management in gas turbine control cabinets, ensuring stable excitation voltage for grid synchronization.

- Precision Manufacturing: Drives servo motors in CNC lathes or robotic arms, enabling micron-level positioning accuracy for aerospace component machining.

- Automated Production Lines: Controls conveyor speed synchronization and packaging machinery via PWM modulation, adapting to real-time load changes.

- Infrastructure Systems: Optimizes pump/fan motor efficiency in water treatment plants using variable frequency control, reducing energy consumption by 10–30%.

Related Products

- IS200JPDGH1A: Simplified power distribution variant without drive control, ideal for auxiliary power panels.

- 531X301DCCAGG2: High-power drive module (75kW) for heavy machinery like crushers or extruders.

- IC697MDL250: Digital I/O expansion module for integrating additional sensors with Mark VIe systems.

- DS200TBQCG1AAA: Terminal board for signal conditioning in turbine control cabinets.

- +E205 EMC Filter: Suppresses electromagnetic interference in sensitive medical imaging equipment linked to drive systems.

Installation and Maintenance

Installation Preparation: Verify input voltage compatibility (220V AC or 24V DC) before wiring. Mount on DIN rail with ≥30mm lateral clearance for heat dissipation. Configure operational mode (power/drive) via jumpers and ground all terminals to prevent electrostatic damage.

Maintenance Recommendations: Clean dust deposits quarterly using compressed air. Calibrate PWM output annually with GE DriveTool software. Replace cooling fans every 40,000 operational hours. Utilize built-in diagnostics for predictive maintenance scheduling.

Product Assurance

GE provides an 18-month warranty covering defects in materials and workmanship. Global technical support includes 24/7 remote diagnostics and on-site service escalation within 48 hours for critical failures. All units undergo IEC 61800-3 (EMC) and ISO 13849 (functional safety) compliance testing.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com