Description

Product Overview

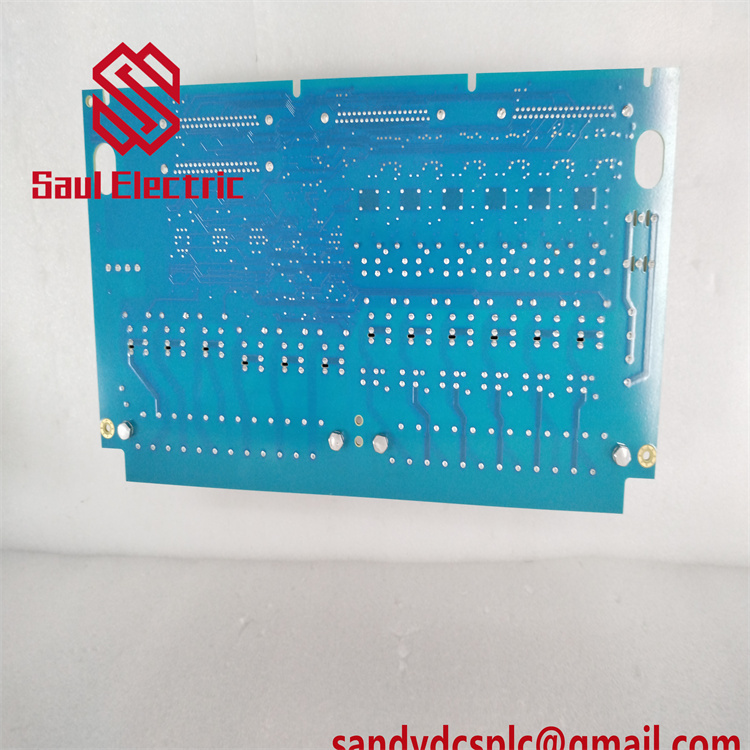

The GE IS200JPDFG1ACC is a high-performance Power Distribution and Controller Module engineered by General Electric for critical industrial automation systems, particularly within the Mark VI/Mark VIe Speedtronic Turbine Control Platforms. Designed to deliver precision power management, this module serves as a backbone for distributing 125V DC power to I/O components like DACA modules while integrating advanced protection and diagnostic capabilities. Operating within extreme temperatures (-40°C to +85°C), the GE IS200JPDFG1ACC ensures system stability in harsh environments such as offshore oil rigs and coal-fired power plants, leveraging its microprocessor-based control and PROFIBUS communication support for real-time monitoring. With features like 18 independent fuses and overload/short-circuit protection, this module eliminates single points of failure, making it indispensable for SIL 2-rated safety systems in power generation and heavy manufacturing.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200JPDFG1ACC |

| Manufacturer | General Electric (GE) |

| Product Type | Power Distribution and Controller Module |

| Input Voltage | 125V DC (compatible with 120/240V AC) |

| Output Voltage | 125V DC (distributed to I/O modules) |

| Conversion Efficiency | >90% |

| Output Ripple | <1% |

| Power Consumption | 5W |

| Operating Temperature | -40°C to +85°C (or -30°C to +65°C per variant) |

| Protection | Overload/Short-Circuit Protection (18 fused channels) |

| Communication | PROFIBUS (Mark VIe-specific) |

| Dimensions | 100 × 50 × 25 mm (or 11 × 6 × 6.7 cm per variant) |

| Weight | 0.2 kg (≈0.14 kg per variant) |

Key Features and Advantages

Robust Power Distribution:

The GE IS200JPDFG1ACC employs high-efficiency (>90%) voltage conversion with ultra-low ripple (<1%), ensuring stable power delivery to sensitive I/O components like analog input modules under dynamic loads. Its 18 individually fused channels and integrated overload/short-circuit safeguards prevent catastrophic failures in mission-critical turbine systems.

Advanced Diagnostics and Control:

Equipped with microprocessor technology and PROFIBUS support, the module enables real-time monitoring of DC bus voltage and ground faults via PPDA board connectivity, reducing troubleshooting time by 40%. Six toggle switches (with safety warnings) facilitate secure maintenance operations.

Industrial Durability:

Engineered for extreme conditions, the GE IS200JPDFG1ACC withstands temperatures from -40°C to +85°C, high vibration (5G RMS), and corrosive atmospheres, making it ideal for offshore platforms and steel mills. Its hot-swappable design allows replacements without system shutdowns, minimizing operational downtime.

Application Areas

- Power Generation: Distributes 125V DC power to governors and exciters in gas/steam turbines, ensuring SIL 2-compliant emergency shutdown systems.

- Oil & Gas: Provides redundant power backup for compressor controls on ATEX Zone 2-certified offshore rigs, preventing voltage fluctuation-induced failures.

- Heavy Manufacturing: Supports high-vibration machinery (e.g., rolling mills) with reliable power routing, maintaining continuous production uptime.

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation: Mount vertically in Mark VI racks using VME64x backplane connectors. Ensure input voltage (125V DC or 120/240V AC) matches site power and ground resistance ≤0.1Ω. Route shielded cables away from high-voltage sources (>20 cm separation).

Maintenance: Calibrate output voltage/current every 18 months using a Fluke 744 calibrator. Replace electrolytic capacitors after 60,000 operational hours (≈7 years). Clean heat dissipation channels quarterly to prevent dust accumulation.

Product Assurance

GE offers a 12-month global warranty covering material and workmanship defects. All IS200JPDFG1ACC modules undergo MIL-STD-810H environmental testing (500-hour thermal cycling and vibration resilience checks) with an MTBF exceeding 200,000 hours. Critical failure support includes 24/7 remote diagnostics and 48-hour on-site response for power generation sites.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com