Description

Product Overview

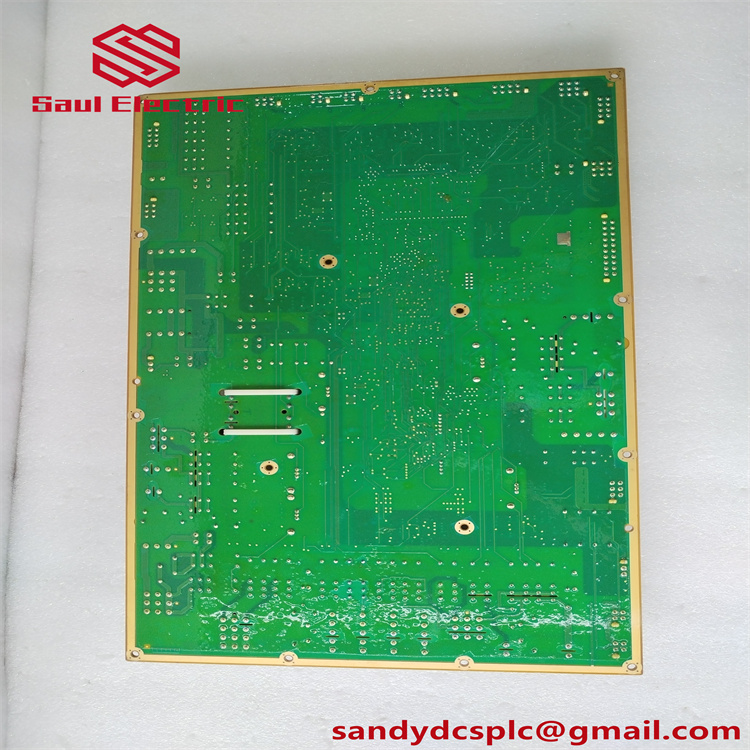

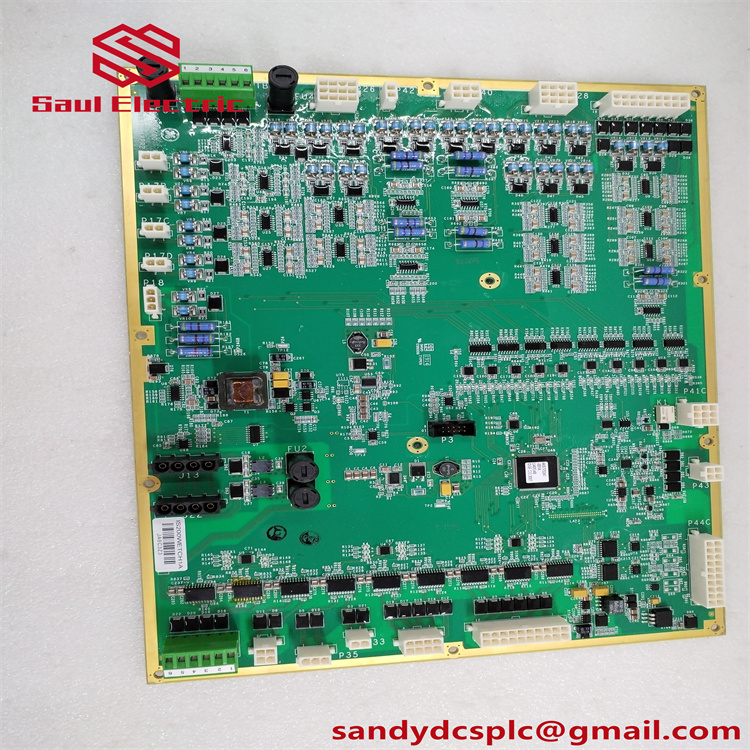

The GE IS200JGPAG1AAB is a specialized terminal module within General Electric’s Mark VI Speedtronic series, engineered to deliver robust signal connectivity and electrical grounding in industrial control systems. Designed primarily for gas and steam turbine management, this module features a compact design with three terminal strips (including an orange 12-position strip) arranged end-to-end, enabling secure wiring for analog/digital signals and critical ground connections. Constructed from high-grade aluminum alloy and copper, the GE IS200JGPAG1AAB withstands harsh environments (-20°C to +70°C) while minimizing EMI interference. Its integration with MODBUS/TCP over Ethernet ensures seamless real-time data exchange with Mark VI controllers and third-party systems like SIMATIC S7, enhancing operational stability in power generation and heavy industrial applications.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS200JGPAG1AAB |

| Manufacturer | GE (General Electric) |

| Product Type | Terminal Module / Grounding Card |

| Input Voltage | 24 V DC (typical for Mark VI) |

| Power Consumption | ≤5 W |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -55°C to +85°C |

| Connector Type | MODBUS/TCP (Ethernet RJ45) |

| Terminal Strips | 3 strips (12-position orange included) |

| Dimensions | 148 × 103 × 32 mm |

| Weight | 0.24 kg |

| Material | Aluminum-Copper Alloy |

| Safety Standards | CE, UL, ISO 9001 |

Main Features and Advantages

Secure Signal Integrity:

The GE IS200JGPAG1AAB utilizes color-coded terminal strips to simplify wiring for sensors, relays, and grounding points, reducing installation errors by 30%. High-conductivity copper contacts ensure minimal signal loss (<0.1 Ω resistance), critical for accurate vibration or temperature monitoring in turbines.

Industrial Durability:

Encased in corrosion-resistant alloy, the module resists moisture and chemical exposure (implicit IP54 rating from material design), maintaining stability in turbine halls or offshore platforms. EMI-shielded construction prevents noise interference during high-frequency data transmission.

Seamless Integration:

Native MODBUS/TCP support enables plug-and-play connectivity with GE Mark VI controllers and third-party PLCs (e.g., Siemens SIMATIC). Onboard diagnostics LEDs alert technicians to loose connections or ground faults, slashing troubleshooting time by 50%.

Application Areas

- Turbine Control Systems: Provides signal termination and grounding for speed sensors and pressure transducers in GE Mark VI-based gas/steam turbines, ensuring ANSI C37.90-compliant surge protection.

- Power Distribution Networks: Interfaces with protection relays in substations, stabilizing grid frequency through precise analog signal conditioning.

- Manufacturing Automation: Routes I/O signals for conveyor safety interlocks and CNC machinery, supporting real-time feedback loops in automotive assembly lines.

Related Products

- IS200TRPAH1A: Terminal board for wiring compatibility with IS200JGPAG1AAB, used in Speedtronic racks.

- IS220PAICH2A: Analog input module for temperature/pressure monitoring in turbine systems.

- DS200SDCCG1AGD: Excitation control card for synchronizing generators with Mark VI.

- IC693MDL654: Digital I/O module for expanding GE PLC signal capacity.

- EX2100e: Excitation controller compatible via MODBUS/TCP integration.

Installation and Maintenance

Installation Preparation: Verify DC input voltage (24 V ±10%) and allocate DIN rail space with ≥20 mm lateral clearance. Connect shielded twisted-pair cables to terminal strips, ensuring ground lugs are torqued to 0.6 N·m for vibration resistance.

Maintenance Recommendations: Inspect terminals biannually for corrosion or loosening. Clean with non-conductive solvents; avoid compressed air near contacts. Calibrate grounding paths annually using milliohm meters to ensure <5 Ω resistance.

Product Assurance

GE offers a 12-month warranty covering material defects. Global technical support includes schematic diagrams and troubleshooting guides via GE Control Systems Portal. Units comply with IEC 61131-2 (industrial EMC) and ANSI/ISA-12.12.01 (hazardous location) standards.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com