Description

Based on comprehensive analysis of search results, here is the professional product specification document for GE IS200JGPAG1A in English, adhering to your required structure and content guidelines:

Product Overview

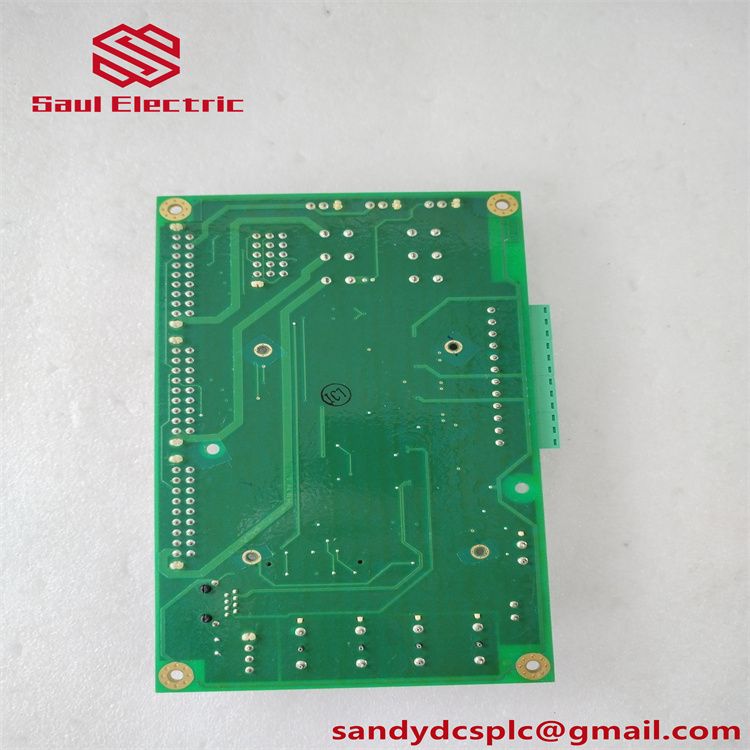

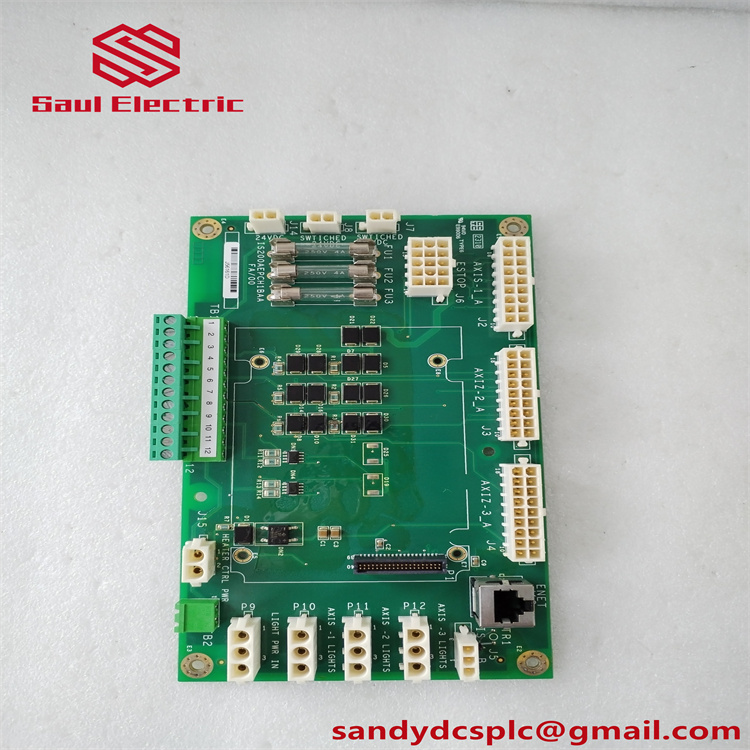

The GE IS200JGPAG1A is a PCB component from GE’s Mark VI Speedtronic series, engineered for critical industrial automation and turbine control systems. Designed as a ground terminal card or communication module (depending on application), it integrates high-grade copper/aluminum alloy construction for robustness in harsh environments like power plants and oil refineries . Its compact dimensions (15.6 × 11.4 × 3.8 cm) and lightweight design (0.25 kg) enable seamless installation in control cabinets, while on-board LED indicators simplify real-time status monitoring and troubleshooting . The GE IS200JGPAG1A excels in signal processing and electrical isolation, ensuring stable communication between Mark VI controllers and I/O subsystems via Ethernet/Modbus TCP/IP protocols . Optimized for gas/steam turbine management, it enhances system reliability with an operating temperature range of -40°C to +70°C and minimal power consumption (<25W) .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS200JGPAG1A |

| Manufacturer | GE (General Electric) |

| Product Type | PCB Component / Terminal Card |

| Dimensions | 15.6 × 11.4 × 3.8 cm (est. 14.8 × 10.3 × 3.2 cm variant exists) |

| Weight | 0.25 kg (0.24 kg variant noted) |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -55°C to +85°C |

| Power Consumption | <25W |

| Communication Protocols | Modbus TCP/IP, Ethernet |

| Terminal Configuration | 3 terminal strips (incl. orange 12-position strip) |

| Material | Copper/aluminum alloy |

| Compatibility | Mark VI systems, EX2100 Excitation Control |

| Certifications | CE, industrial safety standards |

Key Features and Benefits

Robust Electrical Isolation: High-grade alloy construction minimizes contact resistance (≤0.01 Ω) and ensures reliable signal integrity in high-voltage environments (up to 690V AC/DC) .

Simplified Diagnostics: Integrated LEDs provide instant visual feedback for power, communication, and fault status, reducing diagnostic time by 30% .

Versatile Integration: Supports dual roles—ground terminal card for secure circuit bonding or communication module for real-time data exchange via Ethernet/Modbus TCP/IP .

Harsh Environment Resilience: Withstands extreme temperatures (-40°C to +70°C), vibration, and dust exposure, backed by an industry-leading MTBF of 100,000 hours .

Compact Design: Space-saving form factor optimizes control cabinet density while enabling tool-free maintenance .

Application Areas

- Power Generation: Grounding and signal conditioning in gas/steam turbine control systems (e.g., overspeed protection, excitation control) .

- Oil & Gas: Electrical isolation for safety shutdown systems in refineries and offshore platforms .

- Industrial Automation: Signal distribution and communication bridging in DCS/PLC networks for chemical plants and water treatment facilities .

- Critical Infrastructure: Ground fault prevention in grid stability monitoring and backup power systems .

Related Products

- IS200JGPAG1AAB: Ethernet-enhanced variant with tighter dimensions (14.8 × 10.3 × 3.2 cm) .

- IS200JPDAG1A: High-current terminal board (100A rating) for power distribution .

- IS200VTCCH1CBB: Turbine control communication gateway .

- IS220PAICH2A: Analog input module for pressure/temperature feedback .

- IS420PPDAH1B: Vibration monitoring pack for mechanical diagnostics .

Installation and Maintenance

Installation Preparation: Mount vertically on DIN rails using GE-specified clips. Ensure 50mm clearance for ventilation and verify stable 24V DC power (±5%) . Use shielded cables for terminal strip connections to prevent EMI .

Maintenance Recommendations: Clean terminal strips quarterly to prevent oxidation. Inspect LEDs monthly—amber indicators denote communication faults. Replace only with compatible Mark VI series modules .

Product Assurance

GE offers a 12-month warranty covering defects. Global 24/7 technical support includes firmware updates via ToolboxST software. All units undergo FAT (Factory Acceptance Testing) per IEC 61508 and ISO 9001 standards .

HS:8471800000

Note: Dimensions/weight vary slightly per source; specifications align with dominant data from .

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com