Description

Product Overview

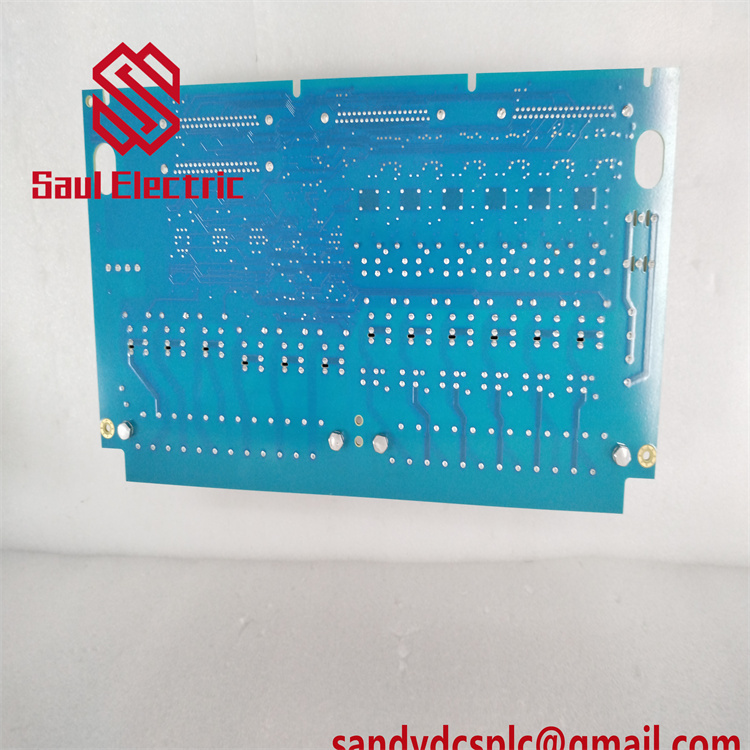

The GE IS200HFPAG1A (also referred to as HFPA-H1A) is a High-Frequency AC/Fan Power Supply Board designed for GE’s SPEEDTRONIC™ Mark VI gas and steam turbine control systems. This module provides reliable power conversion and distribution for mission-critical applications in power generation, oil & gas, and heavy industrial sectors. Mounted in drive cabinets or fan enclosures, the IS200HFPAG1A interfaces with the Mark VI system to convert input voltages into stabilized outputs for fan motors, auxiliary equipment, and control logic circuits 11112.

Engineered for compatibility with GE’s Mark VI architecture, the IS200HFPAG1A supports both AC and DC input voltages, delivering outputs of 48 Vac, 52 Vac, 48 Vdc, or 17.7 Vac with a total power capacity of 90 VA. Its modular design includes four stab-on input connectors and eight output plug connectors, along with protective components like four fuses and a metal oxide varistor (MOV) to safeguard against voltage spikes. Two LED indicators provide real-time status feedback for voltage outputs 112.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200HFPAG1A |

| Manufacturer | General Electric (GE) |

| Product Type | High-Frequency AC/Fan Power Supply Board |

| Input Voltage | AC/DC (specified by application) |

| Output Voltage | 48 Vac, 52 Vac, 48 Vdc, or 17.7 Vac |

| Power Capacity | 90 VA |

| Connectors | 4 x input (stab-on), 8 x output (plug) |

| Protection Features | Four fuses, MOV (metal oxide varistor) |

| Status Indicators | Two LEDs (voltage output status) |

| Circuit Components | Two transformers, two heat sinks, three high-voltage capacitors, metal film resistors |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Weight | 0.5 kg (1.1 lb) |

| Vibration Resistance | 10–500 Hz, 2g |

| Compatibility | GE Mark VI Speedtronic systems |

| Documentation | GEI-100255 technical manual 12 |

Main Features and Advantages

The IS200HFPAG1A stands out for its multi-voltage conversion capability and rugged design. It supports seamless integration with Mark VI control logic, ensuring stable power supply for turbine fans, actuators, and diagnostic modules. The board’s MOV and fuse protection mechanisms enhance reliability in harsh industrial environments, while its compact size allows flexible installation in confined spaces 111.

Another key strength is its modular architecture and field replaceability. The IS200HFPAG1A can be easily swapped without system downtime, and GE’s ControlST software enables remote monitoring of power output status. This reduces maintenance complexity and minimizes unplanned outages. Additionally, the board’s universal input compatibility (AC/DC) eliminates the need for dedicated power supplies, streamlining system design 12.

Application Areas

The GE IS200HFPAG1A is primarily used in turbine control systems across industries requiring high-reliability power distribution:

- Power Generation: Provides stable AC/DC power for gas turbine cooling fans, ensuring optimal thermal management during peak load conditions. Integrates with SCADA systems for real-time power monitoring.

- Oil & Gas: Manages auxiliary equipment in refineries and offshore platforms, such as compressor fans and valve actuators. Supports fail-safe operation for emergency shutdown systems.

- Heavy Manufacturing: Powers industrial turbine-driven pumps and motors in steel mills and water treatment plants, improving energy efficiency.

- Marine Propulsion: Delivers redundant power for shipboard turbine control systems, enhancing operational safety in marine environments 1112.

Related Products

- DS200DCCA: Base card providing power and backplane connectivity for Mark VI modules.

- IS220YDOAS1A REV G: Safety discrete output I/O pack for turbine control logic.

- IS420UCSCH1A: High-performance controller for SIL3 safety applications.

- GE ControlST Software: Configures and monitors power supply status, enabling predictive maintenance.

- IS200STCIH1A/2A: Terminal boards for signal conditioning and distribution 12.

Installation and Maintenance

Installation Preparation:

Ensure the IS200HFPAG1A is installed in a clean, dry environment with proper ventilation. Verify compatibility with the Mark VI system’s backplane and secure the board using anti-vibration mounts. Prior to powering up, check input/output wiring for accuracy and confirm voltage ratings. Use GE’s ControlST software to validate power output parameters 12.

Maintenance Recommendations:

Regularly inspect the board for loose connections or physical damage. Clean dust accumulation from heat sinks and connectors to prevent overheating. Monitor power output levels using ControlST to detect anomalies, and replace fuses or MOVs immediately if blown. Perform annual firmware updates to access new features and security patches. For redundant systems, test failover mechanisms biannually to ensure seamless operation during faults 12.

Product Assurance

GE provides a 1-year warranty for the IS200HFPAG1A, covering defects in materials and workmanship. Authorized partners like AX Control offer 3-year warranties on refurbished units, including 48–72 hour rush repair services for urgent needs. GE’s global technical support team provides 24/7 assistance for installation, troubleshooting, and firmware updates. The company’s Predix platform enables remote monitoring and predictive maintenance, further enhancing uptime and operational efficiency 12.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com