Description

Product Overview

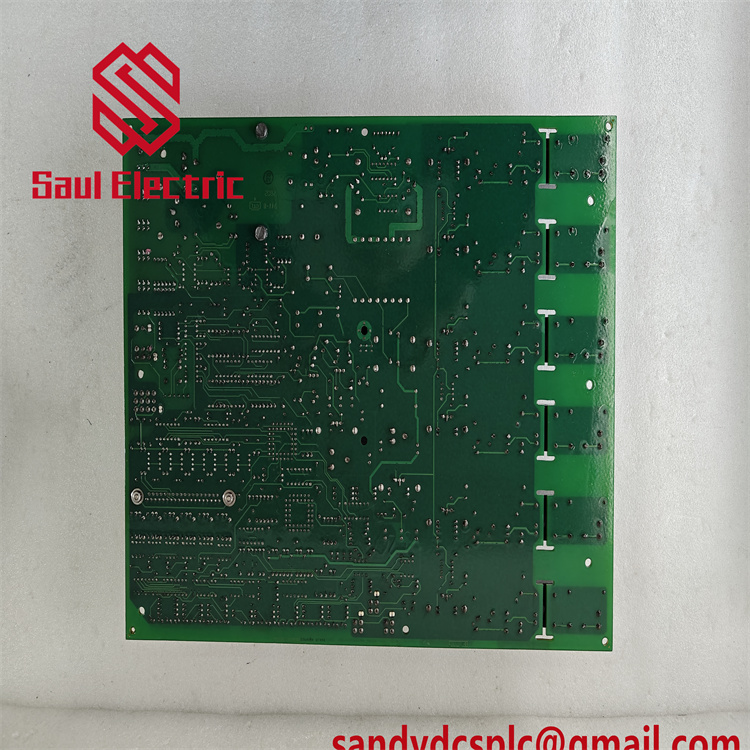

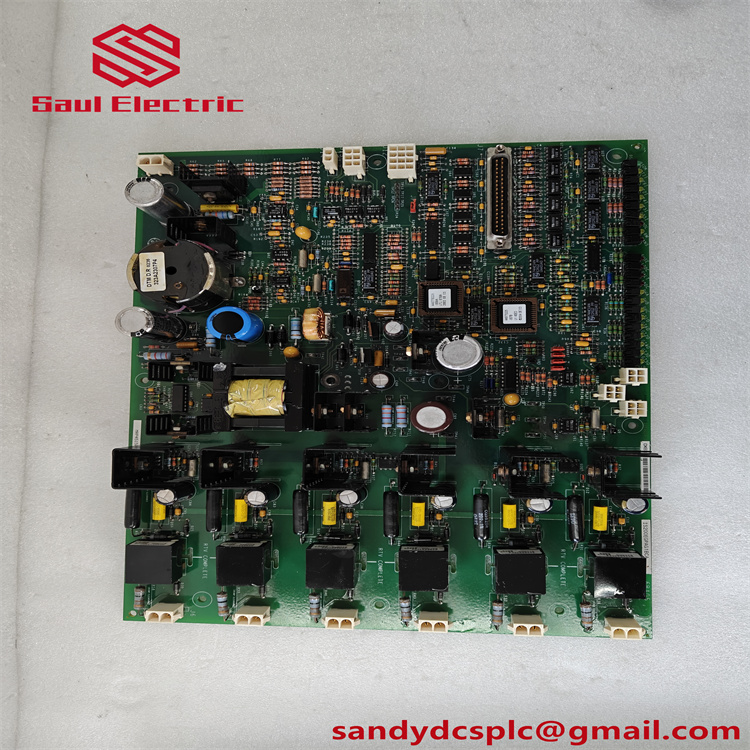

The GE IS200DSVOH1ABA is an industrial-grade Power Supply Board engineered for GE’s Mark VI Speedtronic Turbine Control Systems, delivering robust and stable power distribution in critical industrial environments. Designed to meet stringent reliability standards, this module provides precise voltage regulation (24V DC output) for turbine control components in power generation, oil and gas, and heavy manufacturing applications. With its wide input voltage range (85–264V AC) and high current capacity (41.67A), the GE IS200DSVOH1ABA ensures uninterrupted operation during grid fluctuations or load surges. Its rugged construction features conformal-coated PCBs and advanced thermal management, enabling resilience in extreme temperatures (-40°C to +70°C) and harsh conditions like coal plants or offshore platforms. Integrated safety protocols and certifications (UL, CE, ISO 9001) make it indispensable for SIL 2-rated systems requiring fail-safe power redundancy.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200DSVOH1ABA |

| Manufacturer | General Electric (GE) |

| Product Type | Power Supply Board |

| Input Voltage | 85–264V AC |

| Output Voltage | 24V DC |

| Output Current | 41.67A |

| Power Rating | 1000W |

| Operating Temperature | -40°C to +70°C |

| Dimensions (L×W×H) | 178.2 × 101.6 × 30.5 mm |

| Weight | 1.4 kg |

| Protection Level | IP20 |

| Certifications | UL, CE, ISO 9001 |

| Compatible Systems | GE Mark VI Turbine Control |

Key Features and Advantages

1. Industrial-Grade Power Stability

The GE IS200DSVOH1ABA utilizes advanced voltage regulation technology to maintain ±0.5% output accuracy under dynamic loads (e.g., turbine startups or grid faults). Wide input voltage tolerance (85–264V AC) accommodates unstable power sources common in remote substations or renewable energy sites.

2. Extreme Environment Resilience

Featuring aluminum heat sinks and conformal-coated circuitry, the board dissipates heat efficiently, preventing thermal overload in enclosures near boilers or compressors. Extended temperature range (-40°C to +70°C) and vibration resistance (5G RMS) ensure reliability in coal mills or Arctic oil rigs.

3. Safety and Compliance

Certified for UL, CE, and ISO 9001 standards, the module includes short-circuit protection, overvoltage lockout, and redundant cooling paths. These features prevent catastrophic failures in SIL 2-rated turbine safety systems.

4. Seamless Integration

Hot-swappable design allows replacement without system shutdown. Native compatibility with Mark VI controllers (e.g., IS215UCVEH2AB) and terminal boards simplifies retrofitting. Dual-stage EMI filtering eliminates signal interference from variable-frequency drives (VFDs).

Application Areas

- Power Generation: Primary power source for gas/steam turbine governors and exciters, ensuring voltage stability during load transients.

- Oil & Gas: Supports offshore drilling rig control systems, with corrosion-resistant materials for salt fog environments (DNV-GL certified).

- Manufacturing: Powers high-current actuators in steel-rolling mills, leveraging 41.67A output to drive servo valves without external amplifiers.

- Marine Propulsion: Integrates with shipboard turbine controls, meeting shock/vibration standards for naval applications.

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation: Mount vertically in Mark VI racks using VME64x backplane connectors. Ensure ≤0.1Ω ground resistance and ≥10 cm clearance from high-voltage cables. Verify compatibility with Mark VI firmware v4.0+.

Maintenance: Clean air vents quarterly with dry nitrogen (<20 psi). Calibrate output voltage annually using Fluke 744 calibrator. Replace electrolytic capacitors after 60,000 operational hours (≈7 years).

Product Assurance

GE provides a 12-month global warranty covering material and workmanship defects. Critical failure support includes 24/7 remote diagnostics via GE Digital Support Hub and 48-hour on-site response for power generation sites. All units undergo MIL-STD-810H environmental testing and 500-hour burn-in cycles.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com