Description

Product Overview

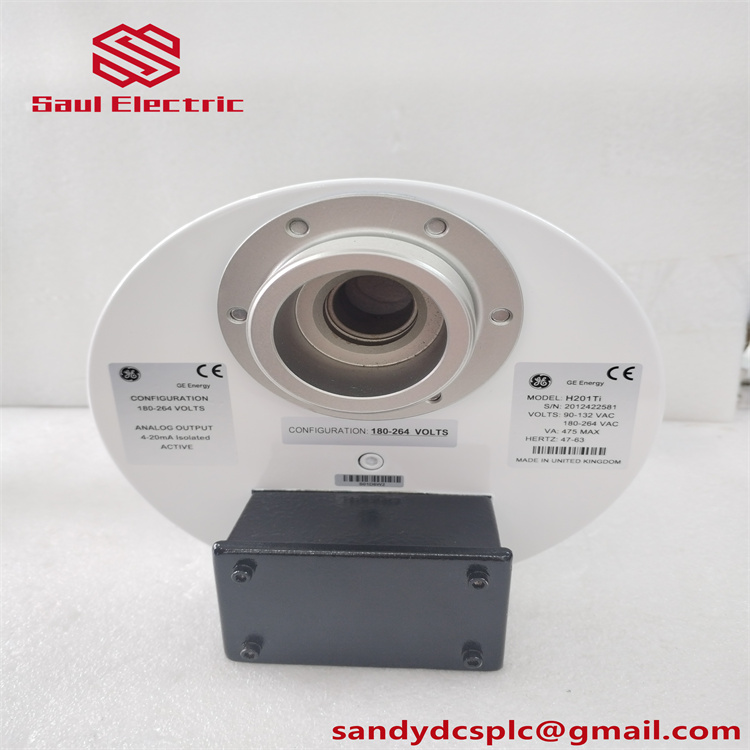

The GE HYDRAN 201TI is a cutting-edge dissolved gas-in-oil analyzer (DGA) engineered for continuous, real-time monitoring of power transformers. As part of GE’s HYDRAN® 201i series, this intelligent transmitter employs patented fuel cell technology to detect dissolved gases (hydrogen, carbon monoxide, acetylene, ethylene) in transformer oil, providing early warnings of thermal or electrical faults 7. Permanently installed on the transformer, the GE HYDRAN 201TI delivers actionable data to support predictive maintenance strategies, minimizing unplanned outages in power generation, oil & gas, and industrial sectors.

The GE HYDRAN 201TI is a cutting-edge dissolved gas-in-oil analyzer (DGA) engineered for continuous, real-time monitoring of power transformers. As part of GE’s HYDRAN® 201i series, this intelligent transmitter employs patented fuel cell technology to detect dissolved gases (hydrogen, carbon monoxide, acetylene, ethylene) in transformer oil, providing early warnings of thermal or electrical faults 7. Permanently installed on the transformer, the GE HYDRAN 201TI delivers actionable data to support predictive maintenance strategies, minimizing unplanned outages in power generation, oil & gas, and industrial sectors.

With a rugged IP66-rated enclosure and wide temperature range (-40°C to +80°C), the GE HYDRAN 201TI withstands harsh outdoor environments, including offshore installations 7. It supports Modbus RTU/RS-485 communication for seamless integration with SCADA systems and GE’s Proficy software, enabling remote monitoring of gas trends and configurable alarm thresholds. The device’s composite gas sensor—100% responsive to hydrogen and sensitive to carbon monoxide, acetylene, and ethylene—aligns with IEEE C57.104 standards for transformer health assessment 7.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE HYDRAN 201TI |

| Manufacturer | General Electric (GE) |

| Product Type | Dissolved Gas-in-Oil Transmitter |

| Power Supply | 110–240V AC (50/60 Hz) |

| Communication | RS-485 Modbus RTU, RS-232 (local) |

| Measurement Range | 0–2000 ppm (hydrogen equivalent) |

| Accuracy | ±10% of reading ±25 ppm (hydrogen) |

| Alarm Outputs | 2 relay contacts (high gas, system fault) |

| Data Logging | Stores 1 year of gas trends/events |

| Operating Temperature | -40°C to +80°C |

| Enclosure Rating | IP66 (weatherproof) |

| Dimensions | 150mm × 240mm × 350mm (5.91in × 9.45in × 13.78in) |

| Weight | 5.6kg (12.35lbs) |

| Mounting | Directly installed on transformer oil valve |

Key Features and Advantages

Continuous Fault Detection: The GE HYDRAN 201TI provides 24/7 monitoring of dissolved gases, detecting early signs of partial discharge, overheating, or arcing. Its “Hydran Gas Value” technology combines multiple gas readings into a single metric, simplifying fault diagnosis and compliance with IEEE standards 7. The sensor’s modular design eliminates moving parts, reducing maintenance costs and extending service life.

Continuous Fault Detection: The GE HYDRAN 201TI provides 24/7 monitoring of dissolved gases, detecting early signs of partial discharge, overheating, or arcing. Its “Hydran Gas Value” technology combines multiple gas readings into a single metric, simplifying fault diagnosis and compliance with IEEE standards 7. The sensor’s modular design eliminates moving parts, reducing maintenance costs and extending service life.

Rugged Design: The weatherproof enclosure and vibration-resistant construction ensure reliable operation in extreme conditions, including saltwater-corrosive offshore environments. The device’s compact form factor (150mm × 240mm × 350mm) optimizes space while maintaining industrial-grade durability 7.

Flexible Integration: Compatible with GE’s H201Ci-1 and Mark IV controllers, the GE HYDRAN 201TI supports networked monitoring of up to 32 units via RS-485, ideal for large transformer fleets. Its RS-232 port enables local configuration and data retrieval without external software 7.

Advanced Data Management: Built-in memory logs gas concentrations, trends, and alarms for historical analysis. Remote access via PC software allows real-time data visualization and firmware updates, enhancing diagnostic efficiency. Optional “hydrogen-only” or “composite gas” sensor configurations cater to specific monitoring needs 9.

Application Areas

- Power Generation: Critical for monitoring power transformers in thermal, nuclear, and renewable energy plants, the GE HYDRAN 201TI prevents catastrophic failures by detecting insulation degradation. It supports predictive maintenance strategies to optimize grid reliability 5.

- Oil & Gas: Deployed in subsea and onshore transformer systems, the device detects gas leaks or degradation, ensuring stable operation in harsh offshore environments. Its IP66 rating protects against saltwater corrosion and extreme temperatures 7.

- Industrial Manufacturing: Used in chemical, pharmaceutical, and food processing facilities, the GE HYDRAN 201TI monitors critical transformers to maintain production continuity. Configurable alarm thresholds adapt to varying equipment requirements 2.

- Smart Grid: Enables utilities to implement condition-based maintenance, reducing unplanned outages and extending transformer lifespans. Data feeds into AI-driven analytics for proactive asset management 9.

Related Products

- GE H201Ci-1 Controller: Paired with the GE HYDRAN 201TI, this single-channel controller provides local display, alarm relay outputs, and analog signals for standalone monitoring 2.

- GE Mark IV Controller: Supports advanced diagnostics and remote access for centralized management of GE HYDRAN 201TI units in multi-transformer installations 9.

- GE Proficy Historian: Software for centralized storage and analytics of GE HYDRAN 201TI data, enabling predictive maintenance modeling and trend analysis 9.

- GE Perception™ Fleet Software: Cloud-based platform for remote monitoring and diagnostics of GE’s DGA devices, including the GE HYDRAN 201TI, with advanced reporting capabilities 9.

- GE HYDRAN M2-X: High-precision DGA system for large transformers, complementing the GE HYDRAN 201TI in hybrid monitoring architectures 9.

Installation and Maintenance

Installation Preparation:

Mount the GE HYDRAN 201TI directly on the transformer’s oil valve using vibration-absorbing pads. Recommended locations include the radiator return pipe or filling valve for optimal oil flow 8. Use shielded cables for power and communication lines to mitigate EMI interference. Ensure proper grounding and ventilation, with 50mm clearance for heat dissipation. Follow GE’s wiring diagrams to connect power inputs and RS-485/RS-232 interfaces 7.

Installation Preparation:

Mount the GE HYDRAN 201TI directly on the transformer’s oil valve using vibration-absorbing pads. Recommended locations include the radiator return pipe or filling valve for optimal oil flow 8. Use shielded cables for power and communication lines to mitigate EMI interference. Ensure proper grounding and ventilation, with 50mm clearance for heat dissipation. Follow GE’s wiring diagrams to connect power inputs and RS-485/RS-232 interfaces 7.

Maintenance Advice:

Calibrate the system annually using GE-certified equipment to maintain accuracy. Inspect sensor connections and cables quarterly for wear or corrosion. Regularly review alarm logs and gas trend reports to identify gradual changes in transformer health. Update firmware periodically to access new features and security patches 7.

Calibrate the system annually using GE-certified equipment to maintain accuracy. Inspect sensor connections and cables quarterly for wear or corrosion. Regularly review alarm logs and gas trend reports to identify gradual changes in transformer health. Update firmware periodically to access new features and security patches 7.

Product Guarantee

GE guarantees the GE HYDRAN 201TI with a 12-month comprehensive warranty, covering manufacturing defects and operational failures. Global technical support provides 24/7 assistance for installation, troubleshooting, and firmware updates. Premium service plans offer onsite maintenance and expedited replacements for mission-critical applications. Every unit undergoes rigorous testing to meet IEC 61000 and IEEE C57.104 standards, reflecting GE’s commitment to industrial-grade reliability 1.

GE guarantees the GE HYDRAN 201TI with a 12-month comprehensive warranty, covering manufacturing defects and operational failures. Global technical support provides 24/7 assistance for installation, troubleshooting, and firmware updates. Premium service plans offer onsite maintenance and expedited replacements for mission-critical applications. Every unit undergoes rigorous testing to meet IEC 61000 and IEEE C57.104 standards, reflecting GE’s commitment to industrial-grade reliability 1.

Brand model: GE HYDRAN 201TI

Product Name: Intelligent Dissolved Gas-in-Oil Transmitter (HYDRAN® 201i Series)

Warranty: 1 year

Size: 150mm × 240mm × 350mm (5.91in × 9.45in × 13.78in)

Weight: 5.6kg (12.35lbs)

Origin: USA

Inventory: Spot/Futures

Delivery time: Goods in stock will be dispatched within 3 days after payment

Order time: Goods will be dispatched within one month after payment

Product Name: Intelligent Dissolved Gas-in-Oil Transmitter (HYDRAN® 201i Series)

Warranty: 1 year

Size: 150mm × 240mm × 350mm (5.91in × 9.45in × 13.78in)

Weight: 5.6kg (12.35lbs)

Origin: USA

Inventory: Spot/Futures

Delivery time: Goods in stock will be dispatched within 3 days after payment

Order time: Goods will be dispatched within one month after payment

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com