Description

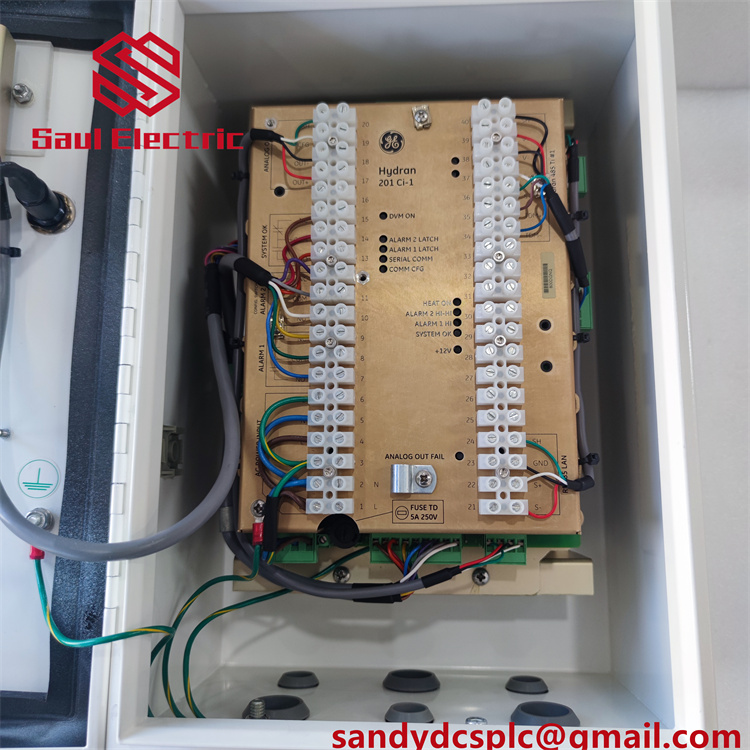

The GE H201Ci-1 is a single-channel controller designed for real-time monitoring of dissolved gases in transformer oil, serving as a critical component of GE’s HYDRAN® 201i online monitoring system. This device integrates with the H201Ti intelligent transmitter to detect early signs of transformer faults by analyzing gas composition (e.g., hydrogen, carbon monoxide, ethylene, acetylene) in oil, enabling predictive maintenance and minimizing downtime in power generation, oil & gas, and industrial sectors 11112.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE H201Ci-1 |

| Manufacturer | General Electric (GE) |

| Function | Single-channel controller for gas monitoring |

| Power Supply | 120V AC (85–132V AC, 50/60 Hz) 15 |

| Communication | RS-232/USB (local) and RS-485 (network) 14 |

| Analog Outputs | Configurable via jumpers: 0–1mA, 4–20mA, 0–1V, 0–10V 514 |

| Alarm Contacts | High gas, high-high gas, system fault 4 |

| Data Logging | Stores up to 1 year of gas trends and events 39 |

| Operating Temperature | -20°C to +60°C (ambient) 14 |

| Enclosure Rating | NEMA 4X/IP66 (weatherproof for outdoor use) 4 |

| Dimensions | 200mm × 150mm × 80mm (7.87in × 5.91in × 3.15in) 14 |

Key Features and Advantages

-

Real-Time Fault Detection:

- Continuously monitors dissolved gases in transformer oil, providing early warnings for thermal or electrical faults (e.g., partial discharge, overheating) 1112.

- Adjustable concentration thresholds (ppm) and rate-of-change alarms to suit specific transformer conditions 39.

-

Flexible Integration:

- Supports Modbus RTU and Hydran protocol for seamless integration with SCADA/DCS systems 311.

- Networkable via RS-485 to connect up to 32 H201Ci controllers, monitoring up to 128 H201Ti transmitters in a distributed network 14.

- Local interface with LED display and 薄膜键盘 for on-site configuration and diagnostics 410.

-

Rugged Design:

- Weatherproof enclosure with conformal-coated PCBs resists dust, moisture, and corrosive environments 414.

- No moving parts or consumables, ensuring low maintenance and long-term reliability 1112.

-

Data Management:

- Built-in memory logs gas concentrations, trends, and events for post-fault analysis 39.

- Remote access via PC software or modem for real-time data visualization and firmware updates 414.

Application Scenarios

- Power Generation: Monitoring power transformers in thermal, nuclear, and renewable energy plants to prevent catastrophic failures 1112.

- Oil & Gas: Detecting gas leaks or degradation in subsea or onshore transformer systems 213.

- Industrial Manufacturing: Ensuring stable operation of critical transformers in chemical, pharmaceutical, and food processing facilities 213.

- Smart Grid: Enabling predictive maintenance strategies to optimize grid reliability and reduce operational costs 1112.

Installation and Maintenance

Setup Requirements:

- Mount the H201Ci-1 within 300m of the H201Ti transmitter to minimize signal degradation 14.

- Use shielded cables for power and communication lines to mitigate EMI interference 14.

- Calibrate the system annually using GE-certified equipment to ensure accuracy 12.

Maintenance Tips:

- Inspect sensor connections and cable integrity quarterly 14.

- Regularly review alarm logs and gas trend reports to identify gradual changes in transformer health 39.

- Update firmware periodically to access new features and security patches 14.

Pricing and Availability

- Price Range: $860–$38,681 USD, depending on configuration (e.g., isolated vs. non-isolated analog outputs, additional communication modules) 178.

- Delivery Time: 3–10 business days for standard configurations; custom orders may take 4–6 weeks 17.

- Warranty: 12-month warranty covering manufacturing defects; extended service plans available for mission-critical applications 17.

Related Products

- GE H201Ti Intelligent Transmitter:

- Paired with the H201Ci-1, it directly measures dissolved gases in transformer oil using a patented sensor array 410.

- GE H201Ci-C Communication Controller:

- Multi-channel version for monitoring up to 4 H201Ti transmitters, ideal for large transformer banks 410.

- GE Proficy Historian:

- Software for centralized storage and analytics of H201Ci-1 data, supporting predictive maintenance models 12.

Compatibility and Upgrades

- Network Expansion: Multiple H201Ci-1 units can be daisy-chained via RS-485 to form a scalable monitoring network 14.

- Firmware Compatibility: Updates are released periodically to enhance functionality and compatibility with newer GE systems 14.

For detailed technical documentation (e.g., wiring diagrams, troubleshooting guides), refer to the GE HYDRAN 201i User Manual. Contact GE’s regional support team for localized installation assistance and customized solutions.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com