Description

Product Overview

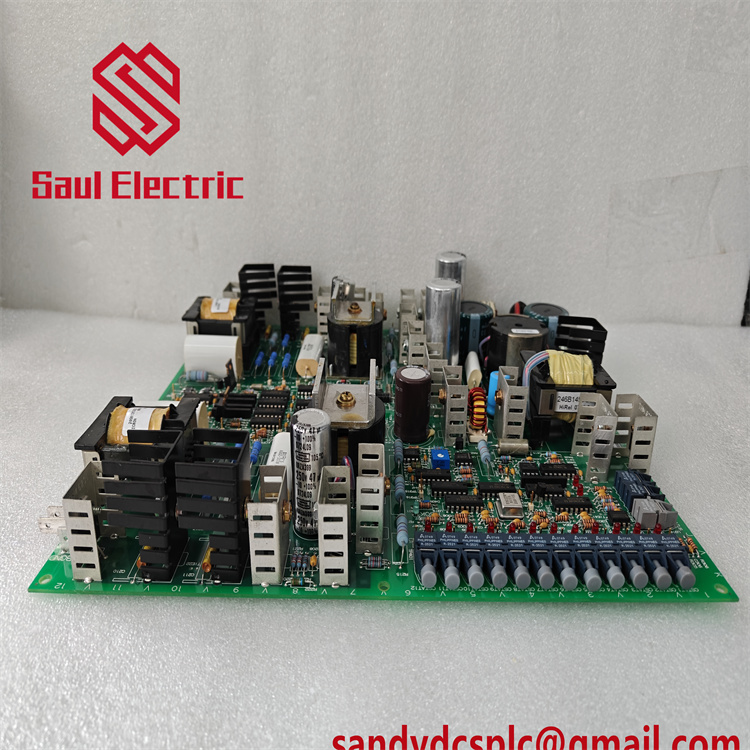

The GE GJR5253100R1260 BCU05G is a high-reliability Backplane Control Unit (BCU) engineered by General Electric, specifically designed for industrial automation systems as part of GE’s advanced Mark VIe control platform. This unit serves as a critical interface for managing data communication and power distribution within modular control systems, enabling seamless integration between various I/O modules and processor units. The GE GJR5253100R1260 BCU05G ensures stable signal transmission and power supply to connected components, making it essential for maintaining the integrity of complex industrial control networks in power generation, oil & gas, and manufacturing sectors.

As a key component of GE’s Mark VIe series, the GE GJR5253100R1260 BCU05G supports hot-swappable module installation, reducing downtime during maintenance or upgrades. Its robust design withstands harsh industrial environments, including high temperatures, vibration, and electromagnetic interference, while delivering consistent performance. The unit’s primary functions include backplane arbitration, power conditioning, and fault monitoring, ensuring optimal system reliability and real-time diagnostic capabilities for mission-critical applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GJR5253100R1260 BCU05G |

| Manufacturer | General Electric (GE) |

| Product Type | Backplane Control Unit (Mark VIe Series) |

| Power Supply | 24V DC (±10%) |

| Power Consumption | ≤30W |

| Communication Protocol | Serial (RS-485) for module status monitoring |

| Backplane Slots | Supports up to 16 I/O modules |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -55°C to +85°C |

| Dimensions (W×H×D) | 200mm × 150mm × 80mm (7.87in × 5.91in × 3.15in) |

| Weight | 1.8kg (3.97lbs) |

| Mounting Type | Rack-mounted (19-inch standard) |

| Redundancy Support | Hot-swappable with redundant power input |

Main Features and Advantages

Rugged Industrial Design: The GE GJR5253100R1260 BCU05G is built with industrial-grade components and a conformal-coated circuit board, ensuring durability in harsh environments. Its fanless design eliminates moving parts, reducing maintenance needs and improving reliability in dusty or high-vibration settings.

Seamless System Integration: As the backbone of Mark VIe control systems, this BCU enables plug-and-play connectivity for I/O modules, processors, and communication cards. It supports standard protocols for easy integration with GE’s Proficy software and third-party SCADA systems, simplifying system design and expansion.

Hot-Swap Capability: The unit allows modules to be replaced without powering down the system, minimizing downtime in critical operations. This feature is vital for industries like power generation, where uninterrupted operation is non-negotiable.

Comprehensive Fault Diagnostics: The GE GJR5253100R1260 BCU05G includes built-in diagnostic functions that monitor power status, module health, and communication integrity. It provides real-time error alerts via status LEDs and serial interfaces, enabling proactive maintenance and rapid issue resolution.

Redundancy Support: With dual power inputs and optional redundant backplane configurations, the BCU ensures system availability even during power fluctuations or component failures, making it suitable for safety-critical applications.

Application Areas

The GE GJR5253100R1260 BCU05G is essential for industrial sectors requiring high-reliability control systems:

- Power Generation: Used in turbine control systems for thermal, nuclear, and renewable energy plants, managing data flow between sensors, actuators, and the main control processor.

- Oil & Gas: Deployed in refineries and offshore platforms to coordinate I/O modules for process control, safety interlocks, and remote monitoring.

- Manufacturing: Integrates with PLC/DCS systems in automotive, pharmaceutical, and food processing plants, enabling precise control over production lines and quality assurance systems.

- Water/Wastewater Treatment: Manages control modules for pump stations, filtration systems, and chemical dosing units, ensuring consistent process performance.

Related Products

- GE GJR5253000R1100 BCU01G: An earlier-generation BCU with fewer slots, suitable for smaller control systems.

- GE GJR5253200R1320 BCU06G: A high-density variant supporting more I/O modules for complex automation setups.

- GE DS200DCFBG1BLC: A DC excitation control module that pairs with the BCU05G in turbine control systems.

- GE IC693CPU364: A compatible PLC processor for hybrid control solutions combining Mark VIe and traditional PLC functionality.

- GE GJR5253100R1261 BCU05H: A hardware-upgraded version with enhanced thermal management for extreme-temperature environments.

- GE Proficy Machine Edition: Software suite for programming and monitoring BCU-connected systems, offering HMI development and data logging.

Installation and Maintenance

Installation Preparation:

Before installing the GE GJR5253100R1260 BCU05G, ensure the control cabinet is properly grounded and ventilated. Verify the power supply (24V DC) and use shielded cables for all connections to minimize EMI interference. Mount the BCU on a 19-inch rack with at least 50mm clearance for heat dissipation, and follow the wiring diagram to connect power inputs and backplane interfaces.

Before installing the GE GJR5253100R1260 BCU05G, ensure the control cabinet is properly grounded and ventilated. Verify the power supply (24V DC) and use shielded cables for all connections to minimize EMI interference. Mount the BCU on a 19-inch rack with at least 50mm clearance for heat dissipation, and follow the wiring diagram to connect power inputs and backplane interfaces.

Maintenance Advice:

Regularly inspect the BCU for loose connections or physical damage, especially after seismic events or high-vibration operations. Use GE’s diagnostic tools to monitor power rail voltages and module statuses monthly. Clean the unit’s vents with compressed air to prevent dust accumulation, and perform firmware updates annually to access the latest security patches. In redundant systems, test failover functionality quarterly to ensure seamless operation during power or module failures.

Regularly inspect the BCU for loose connections or physical damage, especially after seismic events or high-vibration operations. Use GE’s diagnostic tools to monitor power rail voltages and module statuses monthly. Clean the unit’s vents with compressed air to prevent dust accumulation, and perform firmware updates annually to access the latest security patches. In redundant systems, test failover functionality quarterly to ensure seamless operation during power or module failures.

Product Guarantee

GE stands behind the GE GJR5253100R1260 BCU05G with a 1-year comprehensive warranty, covering manufacturing defects and operational failures. Our global technical support team provides 24/7 assistance for installation, troubleshooting, and firmware updates. For critical applications, GE offers premium service plans with onsite maintenance and expedited replacement, ensuring minimal downtime. Every BCU undergoes rigorous testing to meet IEC 61000 and NEMA 4X standards, reflecting our commitment to industrial-grade reliability.

Brand model: GE GJR5253100R1260 BCU05G

Product Name: Backplane Control Unit (Mark VIe Series)

Warranty: 1 year

Size: 200mm × 150mm × 80mm (7.87in × 5.91in × 3.15in)

Weight: 1.8kg (3.97lbs)

Origin: USA

Inventory: Spot/Futures

Delivery time: Goods in stock will be dispatched within 3 days after payment

Order time: Goods will be dispatched within one month after payment

Product Name: Backplane Control Unit (Mark VIe Series)

Warranty: 1 year

Size: 200mm × 150mm × 80mm (7.87in × 5.91in × 3.15in)

Weight: 1.8kg (3.97lbs)

Origin: USA

Inventory: Spot/Futures

Delivery time: Goods in stock will be dispatched within 3 days after payment

Order time: Goods will be dispatched within one month after payment

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com