Description

Product Overview

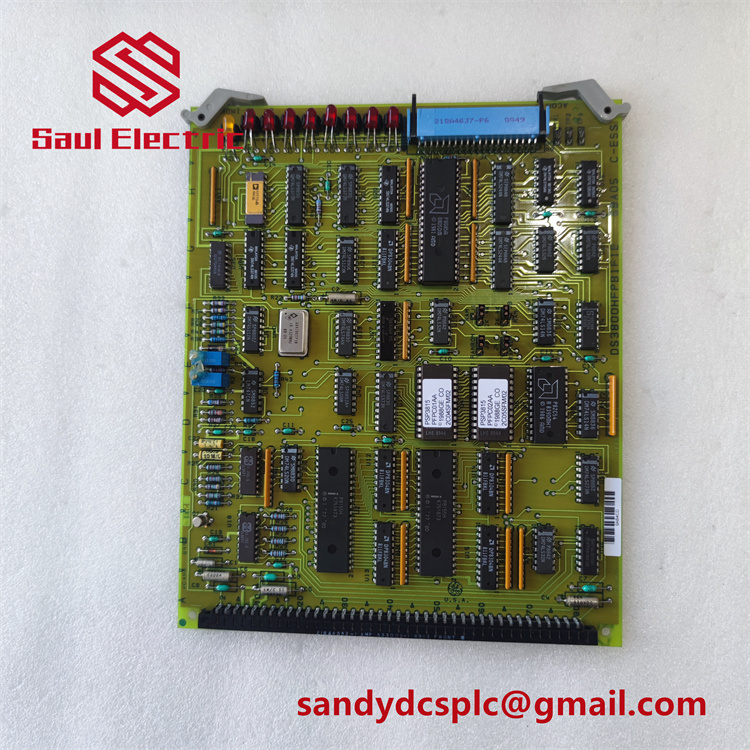

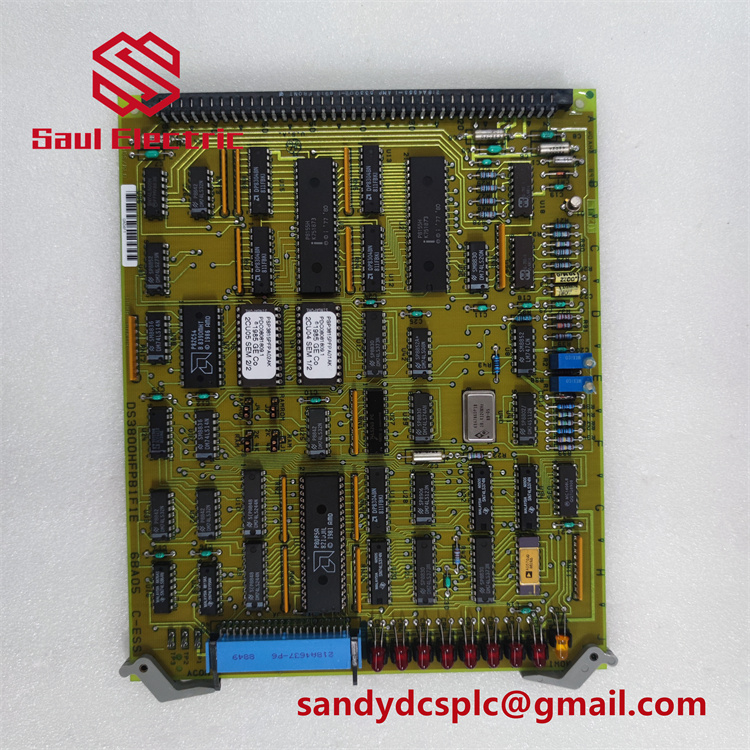

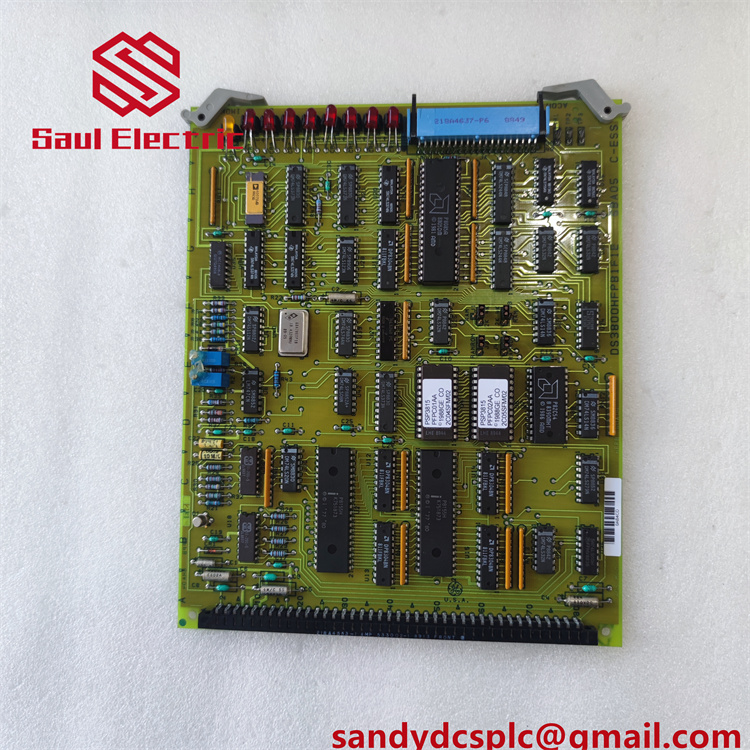

The GE DS3820PIMB is a mission-critical panel interface module designed for GE’s Mark IV Speedtronic turbine control systems. It serves as the human-machine interface (HMI) hub, enabling technicians to monitor and control turbine operations directly from the panel. Comprising two stacked printed circuit boards (PCBs)—including the DS3800NPSM logic board—the module integrates ten functional sections, such as display mode, execute commands, alarm indicators, and an emergency stop button, surrounding a central display cutout 35.

Constructed with a rugged metal enclosure and screw-terminal connections, the DS3820PIMB supports real-time interaction with turbine subsystems, including speed regulation, start-up sequences, and fault diagnostics. Its modular design allows for easy replacement of individual PCBs, while diagnostic LEDs and test points simplify troubleshooting. This module is critical in power generation, oil & gas, and heavy industrial applications where uninterrupted turbine control is essential.

Technical Specifications (Inferred from Similar Models)

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE DS3820PIMB |

| Manufacturer | General Electric |

| Product Type | Panel Interface Module (HMI) for Mark IV Systems |

| Input Voltage | 24 VDC (derived from Mark IV system requirements) |

| Communication Protocol | Proprietary GE Mark IV bus (CAN Bus compatible) |

| Display Interface | 4-line LCD display (via integrated HMI panel) |

| I/O Connections | 6-pin headers for PCB interconnection, ribbon cable for HMI control |

| Operating Temperature | 0°C to +50°C (32°F to 122°F) |

| Protection Class | IP20 (dust protection) |

| Physical Dimensions | 360mm x 556mm x 265mm (14.2″ x 21.9″ x 10.4″) |

| Weight | 2.5 kg (5.5 lbs) |

| Compliance | UL 508, IEC 61000-6-2 (EMC immunity) |

Key Features and Advantages

Integrated HMI Functionality: The DS3820PIMB provides a centralized interface for turbine control, featuring dedicated sections for mode selection, alarm acknowledgment, and parameter adjustment. The LCD display offers real-time data on turbine speed, temperature, and system status 5.

Modular Redundancy: With two stacked PCBs (including the DS3800NPSM), the module supports fault-tolerant operation. The lower PCB handles HMI communication via a ribbon cable, while the upper PCB manages logic processing and power distribution 3.

Rugged Industrial Design: The metal enclosure and reinforced mounting brackets withstand vibration and temperature fluctuations in power plant environments. Internal heat sinks and surge suppressors protect against voltage spikes 5.

Easy Maintenance: Screw-terminal connections and accessible test points allow technicians to replace components without specialized tools. GE’s global repair network offers cost-effective refurbishment for end-of-life units 7.

Compatibility: Designed for seamless integration with Mark IV systems, the DS3820PIMB pairs with power supply modules (e.g., DS3820PSCC1D1B) and relay boards (e.g., DS3820RDMA1) to form a complete control architecture 5.

Application Areas

The GE DS3820PIMB is essential in high-reliability industrial systems:

-

Power Generation:

Enables operators to monitor steam and gas turbines in power plants, adjusting parameters like fuel flow and blade positioning for optimal efficiency. -

Oil and Gas:

Used in offshore platforms and refineries to control wellhead actuators, monitor pressure levels, and manage emergency shutdown sequences. -

Heavy Manufacturing:

Supports CNC machinery and robotics by providing real-time HMI control for motion systems in automotive assembly plants. -

Water/Wastewater Treatment:

Powers PLCs and motor control centers (MCCs), allowing operators to manage pump systems and water purification processes remotely. -

Transportation Infrastructure:

Integrates with railway signaling systems to provide interface control for trackside controllers and communication gateways.

Related Products

- GE DS3820PIMB1A1B: A modified version with enhanced HMI functionality, including a larger display and additional control sections 3.

- GE DS3800NPSM: A logic board integrated into the DS3820PIMB, responsible for processing sensor data and executing control commands.

- GE DS3820PSCC1D1B: A power supply module that provides 24 VDC to the DS3820PIMB and other Mark IV components.

- GE DS3820RDMA1: A relay board that interfaces with the DS3820PIMB to manage turbine shutdown and safety protocols.

- GE IC697PWR731: A redundant power supply module for hybrid control systems, complementary to the DS3820PIMB in large-scale installations.

Installation and Maintenance

Installation Preparation:

- Verify input voltage compatibility (24 VDC) and connect the module to a dedicated circuit breaker.

- Mount the panel using its flanged brackets, ensuring at least 50mm clearance around vents for airflow.

- Connect the ribbon cable between the HMI panel and the lower PCB, securing with six-pin headers 5.

Maintenance Recommendations:

- Inspect ribbon cables for wear every 6 months; replace if frayed.

- Clean dust from vents quarterly to prevent overheating in high-dust environments.

- Use GE-approved test equipment to verify communication bus integrity during system diagnostics.

- For refurbished units, schedule annual recalibration to maintain HMI display accuracy.

Product Assurance

GE offers a 1-year warranty on new DS3820PIMB units, covering defects in materials and workmanship. Refurbished units typically include a 90-day service warranty. The module meets UL 508 and IEC 61000-6-2 standards, ensuring compliance with North American and European safety regulations. GE’s global support network provides 24/7 technical assistance for firmware updates and troubleshooting.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com