Description

Product Overview

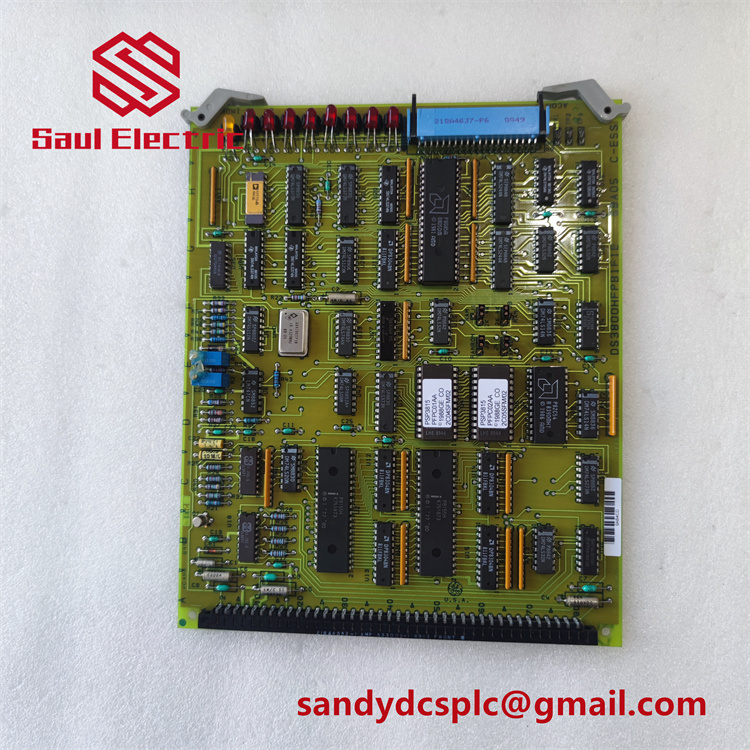

The GE DS3820NGDB is a critical component of GE’s Mark IV Speedtronic turbine control systems, designed to detect and mitigate ground fault conditions in high-voltage industrial environments. As a Field Ground Fault Detector, this module continuously monitors electrical circuits for insulation breakdowns, providing real-time diagnostics to prevent equipment damage and ensure operational safety. Integrating advanced sensor technology and fault analysis algorithms, the DS3820NGDB acts as a vital layer of protection in power generation, oil & gas, and heavy manufacturing applications where uninterrupted system integrity is paramount.

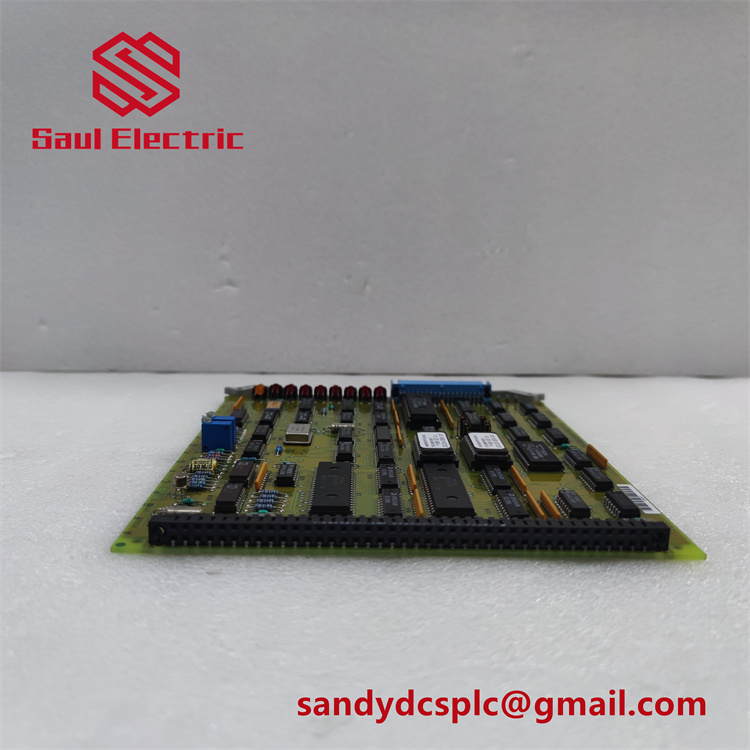

Built with rugged industrial-grade components, the DS3820NGDB interfaces seamlessly with Mark IV control panels, enabling technicians to visualize fault locations and trigger corrective actions through its intuitive HMI interface. Its modular design allows for quick replacement within the Mark IV chassis, minimizing downtime during maintenance. By combining high precision with rapid response times, this detector safeguards against costly outages and extends the lifespan of connected machinery, positioning it as an indispensable asset in mission-critical systems.

The DS3820NGDB supports both AC and DC voltage systems, making it adaptable to diverse industrial setups. Its diagnostic capabilities include phase-to-ground fault detection, leakage current monitoring, and fault severity classification, all of which are communicated via the Mark IV system’s proprietary bus protocol. By embedding the DS3820NGDB into control architectures, operators gain actionable insights to optimize maintenance schedules and reduce unplanned downtime.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE DS3820NGDB |

| Manufacturer | General Electric |

| Product Type | Field Ground Fault Detector |

| Input Voltage Range | 120–600 VAC/DC (universal compatibility) |

| Detection Sensitivity | 0.1–100 mA (adjustable via DIP switches) |

| Response Time | <50 ms (fault isolation) |

| Communication Protocol | Mark IV CAN Bus |

| Physical Dimensions | 300mm x 200mm x 150mm (11.8″ x 7.9″ x 5.9″) |

| Weight | 1.8 kg (4.0 lbs) |

| Operating Temperature | -20°C to +60°C (-4°F to 140°F) |

| Protection Class | IP54 (dust and water splash protection) |

| Mounting Type | Rack-mounted (Mark IV chassis compatible) |

| Compliance | UL 508, IEC 61000-6-2 (EMC immunity) |

Key Features and Advantages

Precision Fault Detection: The DS3820NGDB employs advanced current transformers and digital signal processing to identify ground faults with ±2% accuracy, ensuring reliable protection against both incipient and catastrophic failures. Its adjustable sensitivity settings accommodate varying system requirements, from low-voltage instrumentation to high-power motor control circuits.

Integrated Diagnostic Tools: The module features a built-in OLED display that shows fault type, location, and severity in real time. Diagnostic LEDs indicate power status, communication health, and fault activation, simplifying troubleshooting during routine inspections. Additionally, fault logs are stored in non-volatile memory for post-event analysis.

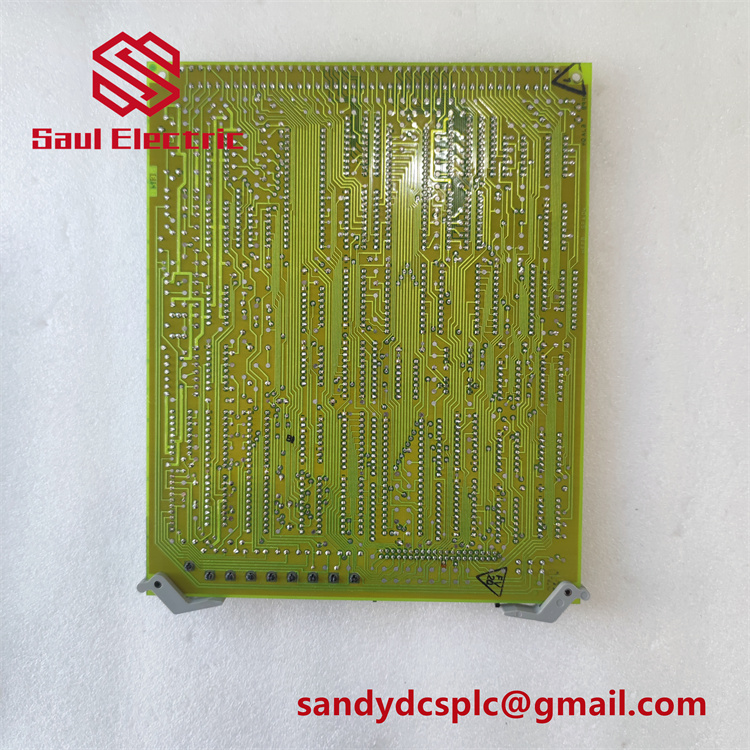

Rugged Industrial Design: Encased in a corrosion-resistant aluminum alloy enclosure, the DS3820NGDB withstands extreme temperatures, vibration, and electromagnetic interference (EMI). Its conformal-coated PCBs and surge-protected inputs ensure longevity in harsh industrial environments.

Seamless System Integration: As part of the Mark IV ecosystem, the DS3820NGDB interfaces directly with control modules like the DS3820PIMB (Panel Interface Module) and DS3820PSCC1D1B (Power Supply Module), enabling centralized monitoring and control. This integration reduces cabling complexity and enhances system interoperability.

Safety-Centric Architecture: The module supports fail-safe operation, automatically triggering emergency shutdowns when critical faults are detected. Its redundant power supply inputs ensure continuous monitoring even during transient voltage fluctuations.

Application Areas

The GE DS3820NGDB is engineered for high-reliability applications requiring robust ground fault protection:

-

Power Generation:

Deployed in steam and gas turbine control systems to monitor generator windings, transformer banks, and auxiliary circuits. Prevents equipment damage from ground faults that could lead to costly outages. -

Oil & Gas:

Installed in offshore platforms and refineries to protect motor control centers (MCCs), pump systems, and wellhead actuators. Ensures compliance with safety standards for explosive environments. -

Heavy Manufacturing:

Used in steel mills and automotive plants to safeguard CNC machinery, robotic arms, and conveyor systems. Reduces downtime by proactively addressing insulation degradation. -

Water/Wastewater Treatment:

Monitors submersible pumps and variable frequency drives (VFDs) in water treatment facilities, minimizing downtime caused by moisture-related faults. -

Mining Operations:

Protects underground haul trucks, conveyor belts, and ventilation systems from ground faults, enhancing worker safety and equipment uptime.

Related Products

- GE DS3820PIMB: Panel Interface Module for Mark IV systems, providing HMI control and status visualization for the DS3820NGDB.

- GE DS3820PSCC1D1B: 24 VDC power supply module that supports the DS3820NGDB and other Mark IV components.

- GE DS3820RDMA1: Relay driver module for executing emergency shutdowns triggered by the DS3820NGDB.

- GE DS3820NGDB1A1A: Upgraded version with extended temperature range and advanced diagnostic capabilities.

- GE IC697PWR731: Redundant power supply for hybrid control systems, ensuring continuous operation of the DS3820NGDB in critical applications.

Installation and Maintenance

Installation Preparation:

- Verify input voltage compatibility and connect the DS3820NGDB to a dedicated circuit breaker.

- Mount the module in a Mark IV chassis using captive screws, ensuring proper alignment with backplane connectors.

- Configure detection sensitivity and communication parameters via DIP switches or the DS3820PIMB interface.

Maintenance Recommendations:

- Inspect terminal connections quarterly for corrosion or 松动.

- Perform calibration checks annually using GE-approved test equipment to ensure detection accuracy.

- Replace the module every 10 years or after a major fault event to maintain peak performance.

- Refer to the DS3820NGDB service manual for detailed troubleshooting procedures.

Product Assurance

GE guarantees the DS3820NGDB against defects in materials and workmanship for 1 year from the date of purchase. Refurbished units include a 90-day warranty. The module meets UL 508 and IEC 61000-6-2 standards, ensuring compliance with global safety and EMC requirements. GE’s global support network offers 24/7 technical assistance, including firmware updates and remote diagnostics. With local inventory in Xiamen, customers benefit from rapid delivery and cost-effective maintenance solutions. For detailed specifications or custom configurations, contact GE’s authorized distributors or visit the official support portal.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com