Description

Product Overview

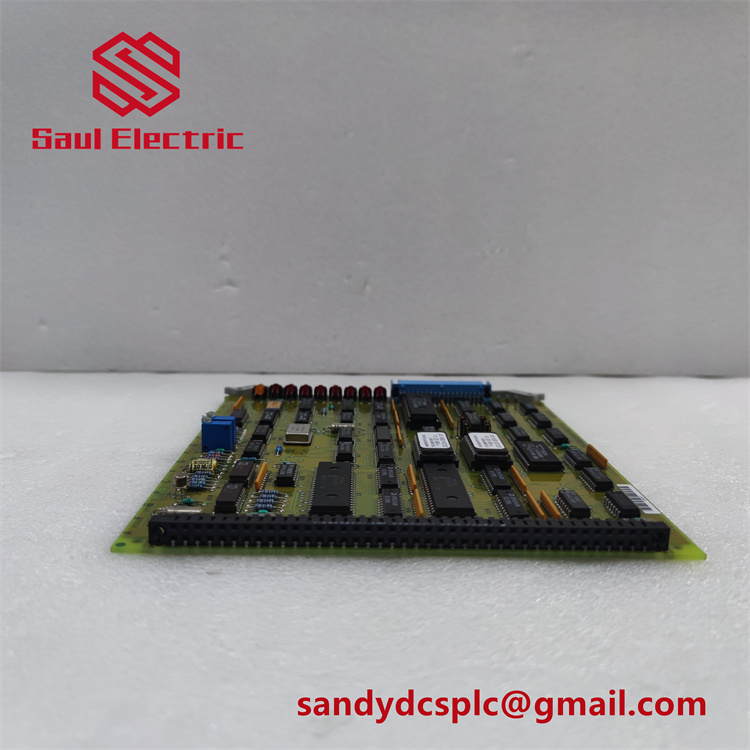

The GE DS3820AISAIA1A is a high-performance Analog Input Module designed for GE’s Mark IV Speedtronic turbine control systems. Engineered to convert analog sensor signals into digital data for real-time system monitoring, this module supports seamless integration of temperature probes, pressure transmitters, and other analog devices in mission-critical industrial environments. As a core component of the Mark IV ecosystem, the DS3820AISAIA1A ensures reliable signal conditioning and noise filtering, making it ideal for gas/steam turbine control, oil & gas platforms, and heavy manufacturing applications.

Featuring 16-channel analog input capability, the DS3820AISAIA1A processes signals from 4-20mA current loops or ±10V voltage sources with 12-bit resolution. Its microprocessor-based architecture provides automatic zero and span calibration, ensuring accurate measurements even in high-vibration or EMI-prone settings. The module interfaces with the Mark IV backplane via a dedicated connector, eliminating the need for external signal converters and reducing cabling complexity.

Built with industrial-grade components, the DS3820AISAIA1A withstands extreme temperatures (-20°C to +60°C) and supports hot-swappable replacement without system shutdowns. Its front-panel LED indicators provide real-time status updates on power, channel activity, and error conditions, simplifying troubleshooting. By embedding this module into control architectures, operators gain actionable insights to optimize system performance and reduce unplanned downtime, making it an indispensable asset in high-reliability applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE DS3820AISAIA1A |

| Manufacturer | General Electric |

| Product Type | Analog Input Module |

| Input Channels | 16 channels (4-20mA/±10V selectable) |

| Resolution | 12-bit ADC |

| Input Impedance | 250Ω (for 4-20mA), 10kΩ (for ±10V) |

| Accuracy | ±0.1% of full scale |

| Physical Dimensions | 280mm x 180mm x 120mm (11.0″ x 7.1″ x 4.7″) |

| Weight | 1.5 kg (3.3 lbs) |

| Operating Temperature | -20°C to +60°C (-4°F to 140°F) |

| Power Requirements | +24V DC (1A) for signal conditioning |

| Protection Class | IP54 (dust and water splash protection) |

| Mounting Type | Rack-mounted (Mark IV chassis compatible) |

| Compliance | UL 508, IEC 61000-6-2 (EMC immunity) |

Key Features and Advantages

High-Accuracy Signal Conditioning: The DS3820AISAIA1A supports 12-bit resolution and ±0.1% accuracy, ensuring precise measurement of critical parameters like turbine inlet temperature and lubrication pressure. Its built-in anti-aliasing filters eliminate high-frequency noise, enhancing data integrity.

Flexible Input Configuration: The module allows users to select between 4-20mA current loops or ±10V voltage inputs via DIP switches, accommodating a wide range of industrial sensors. Each channel can be individually configured for unipolar or bipolar operation.

Rugged Industrial Design: Built to withstand harsh environments, the DS3820AISAIA1A features surge protection, transient voltage suppression, and EMI shielding. Its IP54 rating ensures reliable operation in dusty or humid conditions.

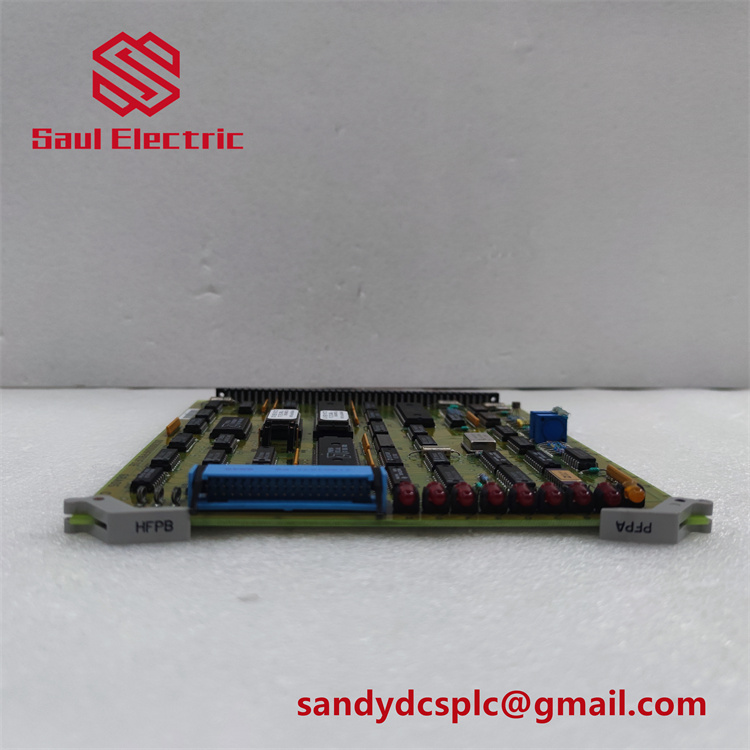

Hot-Swappable Maintenance: The plug-and-play architecture allows module replacement without system downtime. LED indicators on the front panel provide instant visibility into power status, channel activity, and error codes.

Seamless System Integration: As part of the Mark IV ecosystem, the DS3820AISAIA1A works seamlessly with modules like the DS3820PIMB (Panel Interface Module) and DS3820PSCC1D1B (Power Supply Module), enabling centralized monitoring and control. Its dual CAN Bus ports support redundant communication paths for mission-critical applications.

Application Areas

The GE DS3820AISAIA1A is optimized for high-reliability applications requiring accurate analog signal acquisition:

-

Power Generation:

Deployed in gas and steam turbine control systems to monitor temperature, pressure, and vibration levels. Its high accuracy ensures stable operation during grid load changes and prevents overheating in critical components. -

Oil & Gas:

Installed in offshore platforms and refineries to measure wellhead pressure, flow rates, and chemical concentrations. Supports compliance with safety standards for explosive environments through its robust isolation design. -

Heavy Manufacturing:

Used in steel mills and automotive plants to monitor CNC machine tool performance and conveyor belt tension. Reduces downtime by proactively addressing equipment inefficiencies. -

Water/Wastewater Treatment:

Monitors pH levels, flow rates, and pump motor performance in treatment facilities, ensuring continuous operation by providing real-time feedback to PLCs. -

Mining Operations:

Enables accurate measurement of ore conveyor belt speed and crusher load in underground mines. Reduces equipment wear by optimizing operational parameters.

Related Products

- GE DS3820PIMB: Panel Interface Module for Mark IV systems, providing HMI control and status visualization for the DS3820AISAIA1A.

- GE DS3820PSCC1D1B: 24 VDC power supply module that supports the DS3820AISAIA1A and other Mark IV components.

- GE DS3820RDMA1: Relay driver module for executing emergency shutdowns triggered by the DS3820AISAIA1A.

- GE DS3820AISA1A1A: Upgraded version with extended temperature range and advanced diagnostic capabilities.

- GE IC697PWR731: Redundant power supply for hybrid control systems, ensuring continuous operation of the DS3820AISAIA1A in critical applications.

Installation and Maintenance

Installation Preparation:

- Verify input voltage compatibility and connect the DS3820AISAIA1A to a dedicated circuit breaker.

- Mount the module in a Mark IV chassis using captive screws, ensuring proper alignment with backplane connectors.

- Configure input type (current/voltage) and channel parameters via DIP switches or the DS3820PIMB interface.

Maintenance Recommendations:

- Inspect terminal connections quarterly for corrosion or 松动.

- Perform calibration checks annually using GE-approved test equipment to ensure measurement accuracy.

- Replace the module every 10 years or after a major fault event to maintain peak performance.

- Refer to the DS3820AISAIA1A service manual (GEA-10618 or GEH-5600) for detailed troubleshooting procedures.

Product Assurance

GE guarantees the DS3820AISAIA1A against defects in materials and workmanship for 1 year from the date of purchase. Refurbished units include a 90-day warranty. The module meets UL 508 and IEC 61000-6-2 standards, ensuring compliance with global safety and EMC requirements. GE’s global support network offers 24/7 technical assistance, including firmware updates and remote diagnostics. With local inventory support in Xiamen, customers benefit from rapid delivery and cost-effective maintenance solutions. For detailed specifications or custom configurations, contact GE’s authorized distributors or visit the official support portal.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com