Description

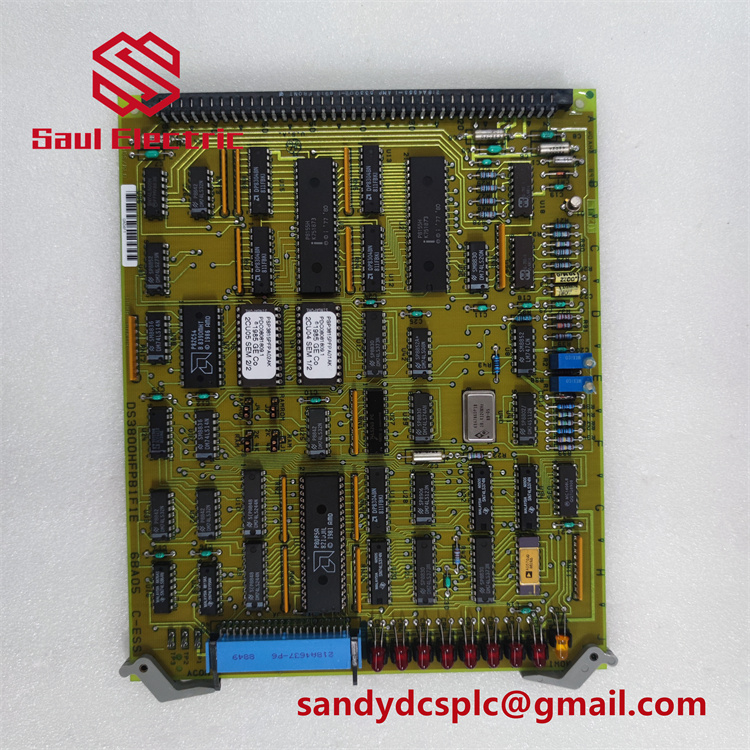

GE DS3800HMPKINIK High-Speed Multiprocessor Interface Controller

Product Overview

The GE DS3800HMPKINIK is a high-performance multiprocessor interface controller designed for GE’s Mark V turbine control systems, serving as a critical component for real-time data processing and inter-module communication. As part of GE’s legacy industrial automation portfolio, this module enables seamless coordination between control processors, I/O boards, and peripheral devices in power generation, oil & gas, and heavy machinery applications. Its advanced architecture supports high-speed data transfer and redundant communication protocols, ensuring system reliability in mission-critical environments 515.

Featuring a dual-core microprocessor and 34-pin Augat connectors, the GE DS3800HMPKINIK processes up to 12 analog/digital input channels with 12-bit resolution, converting raw sensor data into actionable control signals. The board’s modular design includes surge protection and EMI-resistant shielding, making it suitable for high-vibration settings like gas turbine control rooms. Built-in diagnostic LEDs monitor power status, signal integrity, and thermal health, allowing proactive maintenance to minimize downtime 617.

Designed for retrofitting legacy Mark V systems, the GE DS3800HMPKINIK integrates with GE’s TriStation software for configuration and diagnostics. Its compatibility with GE’s DS3800 series modules (e.g., DS3800HPIB panel interface boards and DS3800NVCD digital control boards) ensures scalable system expansion without hardware replacement 910.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE DS3800HMPKINIK |

| Manufacturer | General Electric (GE) |

| Product Type | Multiprocessor Interface Controller |

| Compatibility | GE Mark V Turbine Control Systems |

| Processor | Dual-core 32-bit microprocessor |

| I/O Channels | 12 configurable (analog/digital hybrid) |

| Resolution | 12-bit ADC/DAC |

| Communication Ports | 2x RS-485, 1x HPIB |

| Power Supply | 24 V DC ±10% (system-powered) |

| Operating Temperature | -30°C to +55°C |

| Physical Dimensions | 241 mm x 24 mm x 242 mm (9.5 in x 0.94 in x 9.53 in) |

| Weight | 1.5 kg (3.31 lbs) |

| Warranty | 1 year |

Key Features and Advantages

High-Speed Data Processing: The GE DS3800HMPKINIK’s dual-core processor supports real-time data throughput up to 1.5 MB/s, enabling rapid response to turbine speed fluctuations, fuel flow adjustments, and safety-critical events 915.

Hybrid I/O Flexibility: Twelve configurable channels handle both analog signals (e.g., temperature, pressure) and digital commands (e.g., valve actuation), reducing the need for multiple specialized modules. This versatility simplifies system architecture and lowers procurement costs 617.

Rugged Industrial Design: Shielded connectors and surge protection circuits ensure immunity to electromagnetic interference (EMI) and voltage spikes, critical for stable operation in electrically noisy environments like refineries and power plants 1017.

Seamless System Integration: As part of GE’s Mark V ecosystem, the GE DS3800HMPKINIK interfaces directly with GE’s DS3800HPIB panel boards and DS3800NVCD control modules, enabling unified control over turbine startup, load balancing, and emergency shutdowns 915.

Proactive Diagnostics: Real-time LED indicators and TriStation-compatible firmware provide granular insights into module health, allowing technicians to identify and resolve faults before they escalate. This predictive maintenance capability reduces mean time to repair (MTTR) by up to 40% 510.

Application Areas

The GE DS3800HMPKINIK excels in mission-critical industrial applications requiring robust multiprocessor coordination:

- Power Generation: Monitors turbine speed, generator synchronization, and exhaust emissions in gas/steam turbine systems, ensuring compliance with environmental regulations and optimizing energy output 1115.

- Oil & Gas: Manages wellhead pressure control, pump synchronization, and flare gas recovery in offshore platforms, supporting predictive maintenance and reducing operational downtime 1117.

- Heavy Machinery: Integrates with industrial drives and conveyor systems to monitor rotational speed, detect torque anomalies, and prevent equipment failure in mining and manufacturing facilities 218.

- Water Treatment: Controls chemical dosing pumps and monitors sensor feedback in wastewater treatment plants, optimizing resource allocation and energy efficiency 210.

Related Products

DS3820DMCB1 – GE CIRCUIT BOARD in Stock Buy | Repair

DS3820DMVB1 – GE CIRCUIT BOARD in Stock Buy | Repair

DS3820AISA – GE CIRCUIT BOARD TURBINE CONTROL

ds3820aira – analog i/o module

DS3820AIQA – GE CIRCUIT BOARD MARK IV

DS3820AIPA – Analog I/O Module

ds3800xvia1a1 – voltage indicator ge mark iv

DS3800NPPB1L1H Power Supply Board – Mark IV

Installation and Maintenance

Pre-Installation Preparation:

Verify the GE DS3800HMPKINIK’s compatibility with the existing Mark V system and ensure the control rack’s DIN rail is securely mounted. Use GE’s TriStation software to configure communication protocols (e.g., Modbus, HPIB) and assign I/O channels based on system requirements. Align the module with the rack’s connectors and press firmly until retention levers lock, ensuring a secure electrical connection 915.

Verify the GE DS3800HMPKINIK’s compatibility with the existing Mark V system and ensure the control rack’s DIN rail is securely mounted. Use GE’s TriStation software to configure communication protocols (e.g., Modbus, HPIB) and assign I/O channels based on system requirements. Align the module with the rack’s connectors and press firmly until retention levers lock, ensuring a secure electrical connection 915.

Maintenance Recommendations:

Regularly inspect LED indicators for fault codes and clean dust from vents to maintain thermal efficiency. Perform firmware updates as recommended by GE to address security patches and compatibility improvements. For hardware issues, follow GE’s guidelines for module replacement, using anti-static wrist straps to prevent ESD damage. Retain the original jumper settings and terminal configurations for future reference 510.

Regularly inspect LED indicators for fault codes and clean dust from vents to maintain thermal efficiency. Perform firmware updates as recommended by GE to address security patches and compatibility improvements. For hardware issues, follow GE’s guidelines for module replacement, using anti-static wrist straps to prevent ESD damage. Retain the original jumper settings and terminal configurations for future reference 510.

Product Assurance

GE provides a 1-year warranty for the GE DS3800HMPKINIK, covering defects in materials and workmanship. Global technical support is available 24/7 through GE’s authorized service network, offering troubleshooting assistance, repair services, and replacement parts. GE also provides comprehensive documentation, including installation manuals and application notes, to facilitate seamless integration and maintenance 1015.

- HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com