Description

GE DS3800HMHA1 MH Controller Module

Product Overview

The GE DS3800HMHA1 is a mission-critical MH controller module designed for GE’s Mark IV Speedtronic turbine control system, delivering real-time data processing and system coordination in industrial gas and steam turbine applications. As part of the DS3800HMHA series, this module integrates seamlessly with Mark IV I/O boards, communication modules, and HMIs to enable precise turbine speed regulation, load balancing, and safety interlocks.

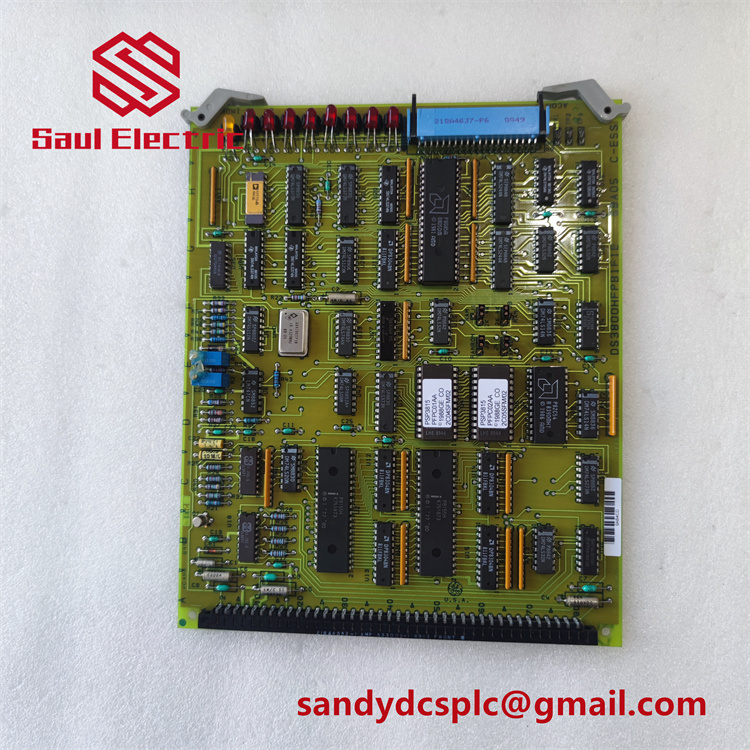

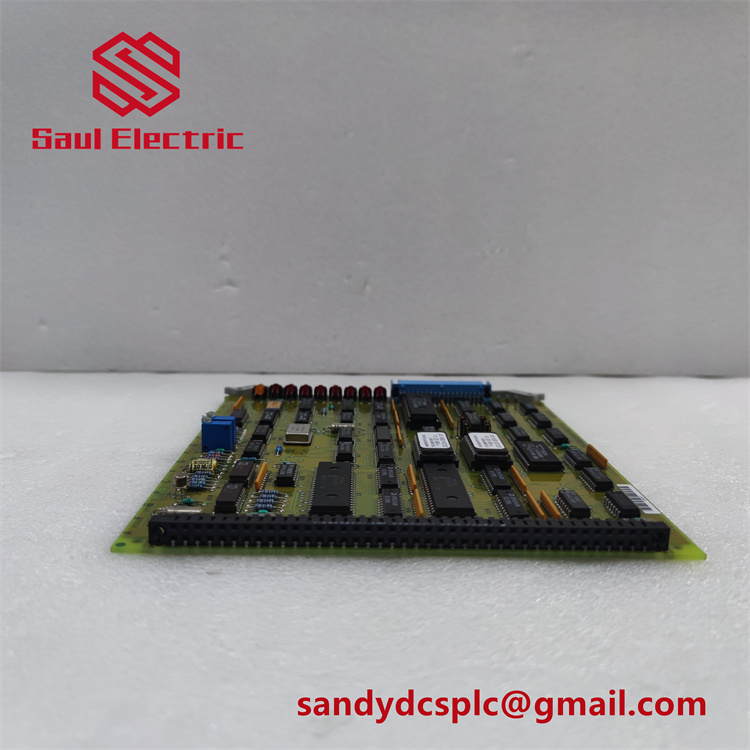

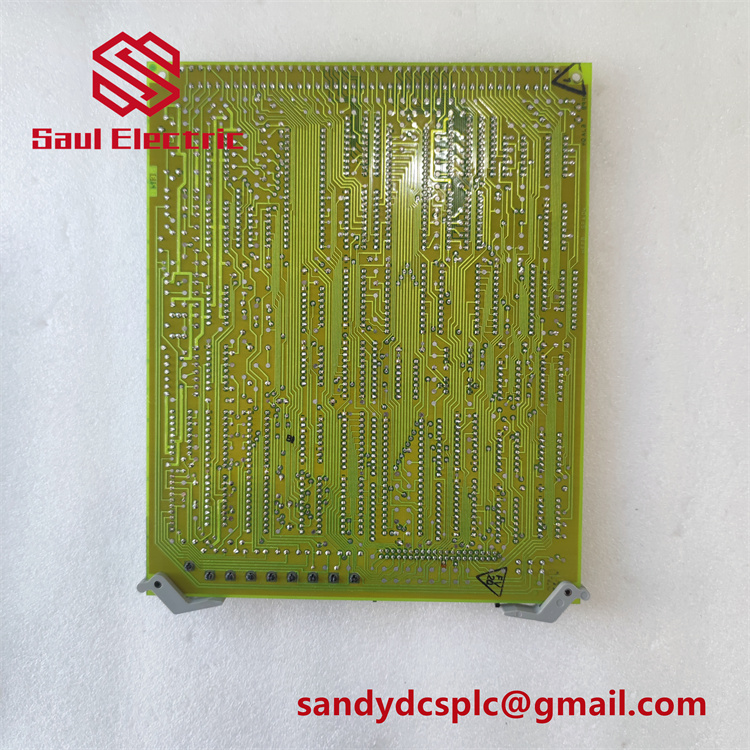

Engineered for high-reliability environments, the GE DS3800HMHA1 features a compact, rugged design with dual extractor clips for easy removal and replacement in rack-mounted systems 1. Its dual-sided PCB houses over 50 integrated circuits, including resistor networks, capacitors, and diodes, supported by jumper switches that allow field-configurable settings for voltage thresholds, signal conditioning, and communication protocols. The module includes three LED indicators (two red, one yellow) for real-time status monitoring, providing diagnostic insights into power, data transmission, and fault conditions 1.

While the Mark IV series is legacy technology, the GE DS3800HMHA1 remains essential for maintaining aging infrastructure in power plants, refineries, and offshore platforms. Its robust construction—with EMI shielding and surge protection—ensures stable performance in high-vibration, extreme-temperature environments (-30°C to +55°C), aligning with GE’s reputation for industrial durability 1.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE DS3800HMHA1 |

| Manufacturer | General Electric (GE) |

| Product Type | MH Controller Module |

| Compatibility | GE Mark IV Speedtronic Turbine Control System |

| Weight | 0.63 lbs (0.286 kg) |

| Physical Dimensions | 9 in x 5.5 in x 1.5 in (228.6 mm x 139.7 mm x 38.1 mm) |

| Connectors | 2 right-angled connectors with cable-securing clips, backplane connector |

| Indicators | 3 LEDs (2 red, 1 yellow) for power, data, and fault status |

| Jumpers | Configurable jumpers for voltage thresholds, signal conditioning, and protocols |

| Power Supply | 12 V DC ±10% (inferred from Mark IV system standards) |

| Operating Temperature | -30°C to +55°C |

| Warranty | 1 year (third-party suppliers, e.g., AX Control, Amikon) |

| Expansion Capability | Vertical pin connector for daughterboard integration |

Key Features and Advantages

Rugged Industrial Design: The GE DS3800HMHA1 features a reinforced enclosure with EMI shielding and surge protection, ensuring reliable operation in high-vibration, extreme-temperature environments. Its dual extractor clips simplify maintenance by allowing quick removal without tools, reducing downtime during repairs 1.

Diagnostic Visibility: Three LED indicators provide real-time feedback on power status, data transmission integrity, and fault conditions, enabling rapid troubleshooting. This feature is critical for minimizing operational disruptions in mission-critical applications like power generation 1.

Field-Configurable Flexibility: Jumpers allow users to adjust voltage thresholds, signal conditioning parameters, and communication protocols, making the GE DS3800HMHA1 adaptable to diverse control scenarios without hardware modifications. This flexibility is ideal for retrofitting legacy systems with modern sensors or actuators 1.

Legacy System Compatibility: As a core component of the Mark IV system, the GE DS3800HMHA1 ensures seamless integration with existing I/O modules (e.g., DS3800HIOD1G1E digital I/O boards) and communication modules (e.g., DS3800HMPG network controllers), preserving investment in aging infrastructure 1.

Application Areas

The GE DS3800HMHA1 excels in industrial environments requiring precise turbine control and diagnostic capabilities:

- Power Generation: Manages turbine speed regulation, generator synchronization, and emissions control in gas/steam turbines, optimizing energy output and grid stability.

- Oil & Gas: Controls wellhead pressure, pump synchronization, and safety interlocks in offshore platforms and refineries, ensuring compliance with environmental and operational standards.

- Heavy Machinery: Monitors rotational speed and torque in mining crushers and conveyor systems, preventing equipment failure and enhancing operational efficiency.

- Industrial Automation: Executes high-speed data processing for complex tasks like material handling and process optimization in manufacturing plants.

Related Products

DS3820DMCB1 – GE CIRCUIT BOARD in Stock Buy | Repair

DS3820DMVB1 – GE CIRCUIT BOARD in Stock Buy | Repair

DS3820AISA – GE CIRCUIT BOARD TURBINE CONTROL

ds3820aira – analog i/o module

DS3820AIQA – GE CIRCUIT BOARD MARK IV

DS3820AIPA – Analog I/O Module

ds3800xvia1a1 – voltage indicator ge mark iv

DS3800NPPB1L1H Power Supply Board – Mark IV

Installation and Maintenance

Installation Preparation: Verify compatibility with the Mark IV system and ensure the control rack’s DIN rail is securely mounted. Align the GE DS3800HMHA1 with the backplane connector and engage the extractor clips for a secure fit. Use GE’s TriStation software to configure jumpers for voltage thresholds, signal conditioning, and communication protocols. Anti-static wrist straps are recommended during handling to prevent ESD damage 1.

Maintenance Recommendations: Regularly inspect connectors for corrosion and clean dust from vents to maintain optimal airflow. Monitor LED indicators for 异常 statuses (e.g., steady red for faults) and address issues promptly. Perform firmware updates as recommended by GE or third-party suppliers. For hardware replacement, retain original jumper settings and terminal configurations for reference. Periodically test diagnostic functions to ensure LED and jumper responsiveness 1.

Product Assurance

The GE DS3800HMHA1 is backed by a 1-year warranty covering defects in materials and workmanship, provided by third-party suppliers like AX Control and Amikon. Global technical support is available through authorized service networks, offering troubleshooting assistance, firmware updates, and replacement parts. This ensures minimal downtime and sustained performance for legacy systems.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com