Description

GE DS3800HCMCIA1A: High-Precision Analog Input Daughter Board

Product Overview

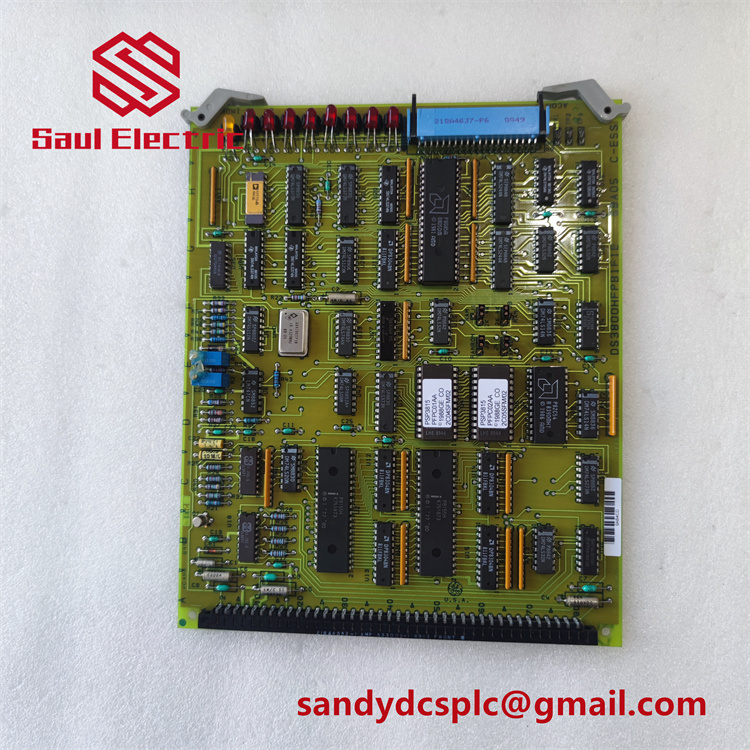

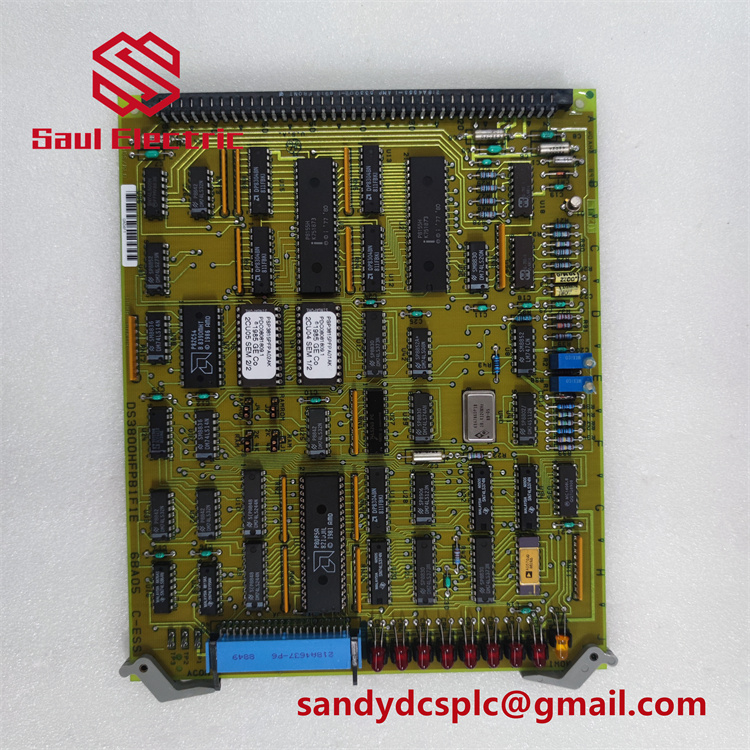

The GE DS3800HCMCIA1A is a high-precision analog input daughter board designed for GE’s Mark IV Speedtronic turbine control system, serving as a critical interface for converting analog sensor signals into digital data for industrial gas and steam turbine applications. As part of the DS3800HCMC series, this module integrates seamlessly with Mark IV mainframes to enable real-time signal acquisition, conditioning, and diagnostic feedback in mission-critical environments .

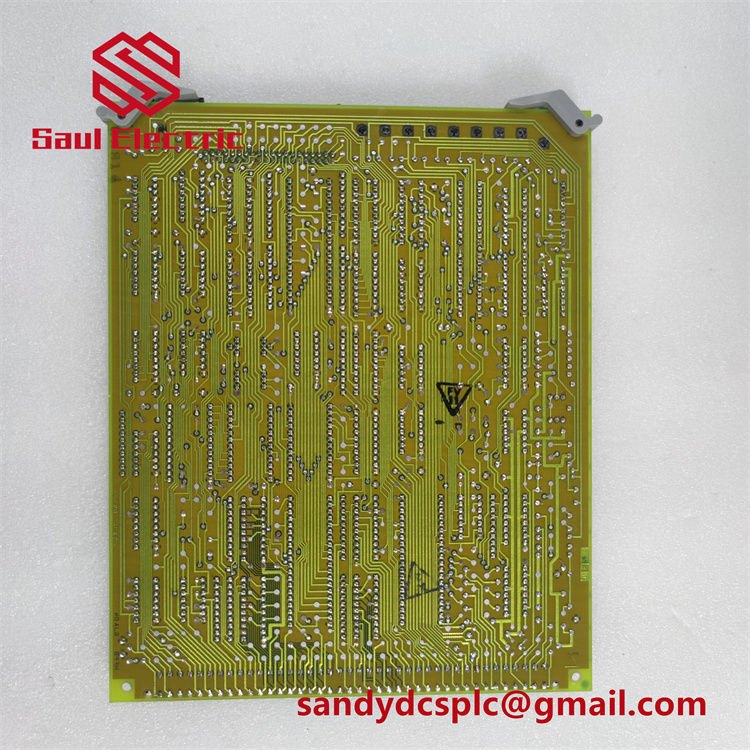

Engineered with 14 field-configurable jumpers and three LED indicators (1 amber, 2 red), the GE DS3800HCMCIA1A supports ±10 V DC voltage inputs and 4–20 mA current loops, ensuring compatibility with legacy transducers, pressure transmitters, and modern smart sensors. Its dual-sided PCB features two 34-pin connectors for direct signal routing to the main processor and multiple capacitors/resistors for noise filtering and signal stabilization. The board includes EPROM sockets for storing calibration parameters, which must be transferred from the original board during replacement .

While the Mark IV series is legacy technology, the GE DS3800HCMCIA1A remains indispensable for maintaining industrial infrastructure in power plants, offshore platforms, and heavy manufacturing facilities. Its wide operating temperature range (-30°C to +65°C) and EMI/RFI shielding ensure reliable performance in harsh environments, while its compact form factor (10.16 cm x 6.35 cm) simplifies integration into space-constrained control racks .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE DS3800HCMCIA1A |

| Manufacturer | General Electric (GE) |

| Product Type | Analog Input Daughter Board |

| Compatibility | GE Mark IV Speedtronic Turbine Control System |

| Signal Standards | ±10 V DC (voltage), 4–20 mA (current loop) |

| Connectors | 2 x 34-pin modular connectors (input/output) |

| Indicators | 1 amber LED (power status), 2 red LEDs (channel fault indicators) |

| Jumpers | 14 configurable jumpers for signal conditioning and protocol selection |

| EPROM Modules | Removable EPROM sockets for calibration storage |

| Power Supply | +5V DC ±10% (via Mark IV system backplane) |

| Operating Temperature | -30°C to +65°C |

| Physical Dimensions | 10.16 cm (H) x 6.35 cm (W) |

| Weight | 0.82 lbs (0.372 kg) |

| Warranty | 1–2 years (third-party suppliers, e.g., AX Control, World of Controls) |

| Expansion Capability | Requires integration with Mark IV main processor board |

Key Features and Advantages

Multi-Protocol Signal Acquisition: The GE DS3800HCMCIA1A supports both voltage and current inputs, allowing simultaneous monitoring of temperature, pressure, and flow sensors. Its 14 jumpers enable field technicians to configure signal scaling, filtering, and HART protocol compatibility without software reconfiguration .

Diagnostic Visibility: Three LEDs provide real-time feedback on power status and channel health. For example, a steady amber light indicates normal operation, while blinking red LEDs signal communication errors or sensor failures. The board also includes self-test diagnostics that verify analog-to-digital conversion accuracy during system startups .

Rugged Industrial Design: Built with EMI/RFI shielding and surge protection, the module withstands voltage spikes and electromagnetic interference common in industrial environments. Its drilled mounting holes and retention levers ensure secure installation in vibration-prone applications like gas turbines .

Calibration Flexibility: The GE DS3800HCMCIA1A uses removable EPROM modules to store calibration coefficients, allowing technicians to transfer settings between replacement boards. This minimizes downtime during hardware swaps, as calibration parameters do not need to be re-entered manually .

Long-Distance Signal Transmission: The board’s 4–20 mA current loop support ensures noise-resistant signal transmission over distances exceeding 1,000 meters, making it ideal for distributed control systems in power plants and oil refineries .

Application Areas

The GE DS3800HCMCIA1A excels in industrial environments requiring precise analog signal acquisition and conditioning:

- Power Generation: Converts analog signals from turbine vibration sensors and temperature probes into digital data for Mark IV controllers, enabling predictive maintenance and load balancing .

- Oil & Gas: Manages inputs from wellhead pressure transmitters and flow meters in offshore platforms. Its surge protection safeguards against voltage transients caused by lightning strikes or equipment faults .

- Heavy Machinery: Processes analog feedback from hydraulic system pressure sensors in mining crushers and conveyor belts, ensuring optimal performance and minimizing mechanical wear .

- Industrial Automation: Integrates with GE’s Mark IV I/O modules (e.g., DS3800HIOD1G1G digital I/O boards) to enable hybrid control systems in manufacturing plants, optimizing material handling and process control .

Related Products

DS3820DMCB1 – GE CIRCUIT BOARD in Stock Buy | Repair

DS3820DMVB1 – GE CIRCUIT BOARD in Stock Buy | Repair

DS3820AISA – GE CIRCUIT BOARD TURBINE CONTROL

ds3820aira – analog i/o module

DS3820AIQA – GE CIRCUIT BOARD MARK IV

DS3820AIPA – Analog I/O Module

ds3800xvia1a1 – voltage indicator ge mark iv

DS3800NPPB1L1H Power Supply Board – Mark IV

Installation and Maintenance

Installation Preparation: Verify compatibility with the Mark IV system and ensure the main processor board is powered off. Align the GE DS3800HCMCIA1A with the backplane connector and secure it using retention levers. Use GE’s TriStation software to configure jumpers for signal conditioning and calibration. Anti-static wrist straps are mandatory during handling to prevent ESD damage .

Maintenance Recommendations: Regularly inspect connectors for corrosion and clean dust from vents to maintain optimal airflow. Monitor the LEDs for 异常 statuses (e.g., blinking red for faults) and address issues promptly. Perform firmware updates as recommended by GE or third-party suppliers. For hardware replacement, transfer EPROM modules from the defective board to the new one and retain original jumper settings for reference. Periodically test diagnostic functions to ensure LED responsiveness .

Product Assurance

The GE DS3800HCMCIA1A is backed by a 1–2 year warranty covering defects in materials and workmanship, provided by third-party suppliers like AX Control (1-year) and World of Controls (24-month). Global technical support is available through authorized service networks, offering troubleshooting assistance, firmware updates, and replacement parts. This ensures minimal downtime and sustained performance for legacy systems .

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com