Description

GE DS3800HAFAID Analog Amplifier Card

Product Overview

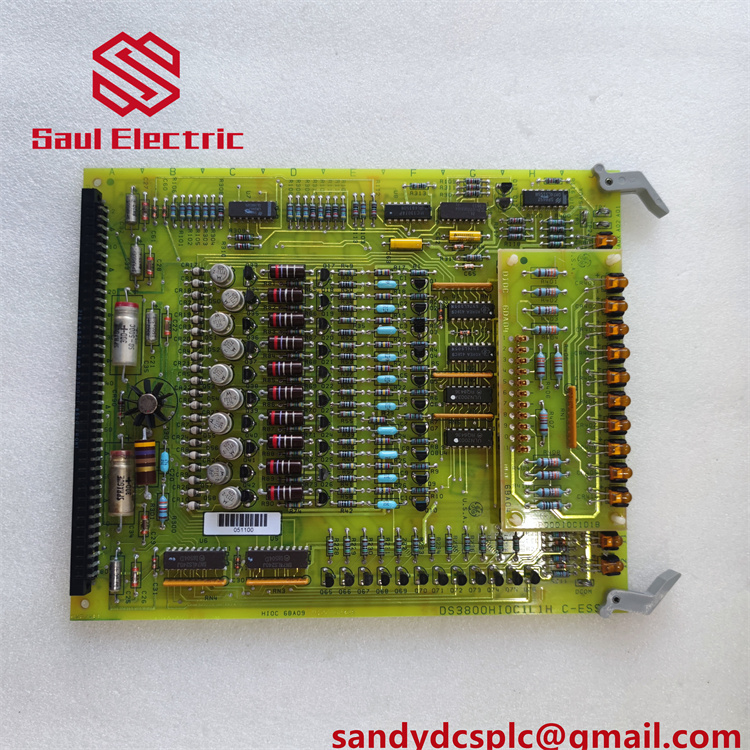

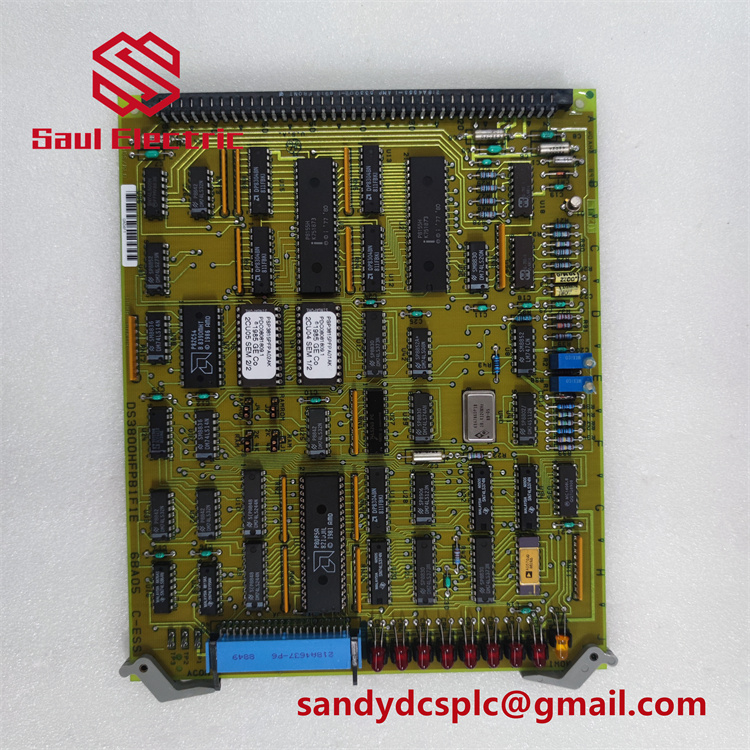

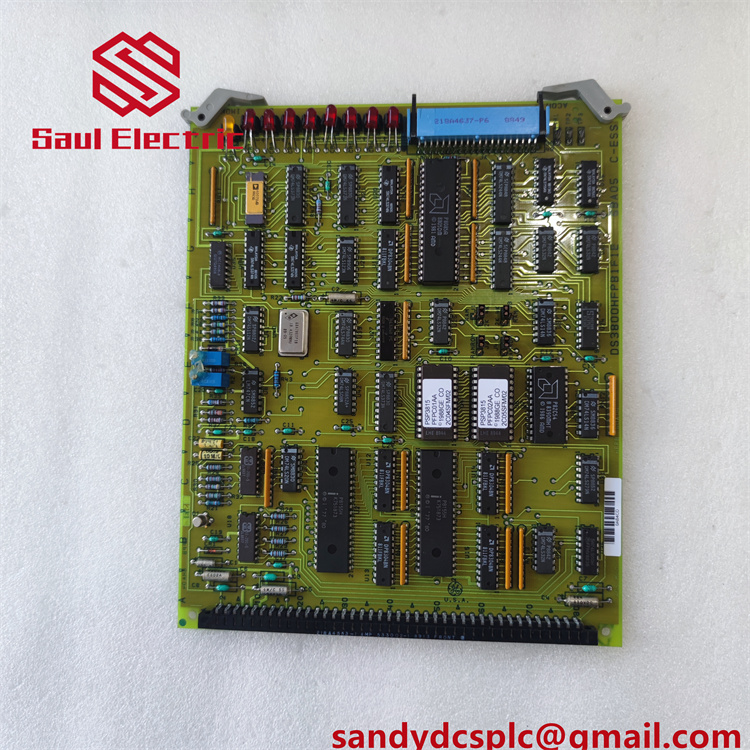

The GE DS3800HAFAID is a high-performance analog amplifier card designed for critical industrial control systems, particularly within GE’s Mark IV Speedtronic turbine control platform. Engineered to deliver precise signal conditioning and amplification, this module plays a pivotal role in converting analog inputs from sensors (e.g., temperature, pressure, or speed) into actionable control signals for gas turbines, steam turbines, and other rotating machinery. As part of the DS3800 series, the GE DS3800HAFAID combines advanced analog processing capabilities with rugged durability, making it ideal for harsh industrial environments where reliability and accuracy are paramount.

Featuring 11 configurable jumpers and 4 trimmer resistors, the GE DS3800HAFAID allows users to tailor its functionality to specific application requirements, such as gain adjustment, signal filtering, or offset compensation. Its modular design includes a 20-pin and 34-pin connector for seamless integration with other Mark IV system components, ensuring compatibility with legacy and modern control architectures. With built-in diagnostic test points (e.g., ES, DV, CLK) and an EEPROM socket for firmware updates, the module enables proactive maintenance and minimizes downtime. Whether used in power generation, oil and gas, or heavy manufacturing, the GE DS3800HAFAID ensures stable operation and precise control, aligning with industry standards like ISO 9001 for quality assurance.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | GE DS3800HAFAID |

| Manufacturer | General Electric (GE) |

| Product Type | Analog Amplifier Card (Mark IV Series) |

| Nominal Voltage | 12 V DC |

| Input Range | ±10 V DC (Analog) |

| Output Range | 0–10 V DC or 4–20 mA (Programmable) |

| Jumpers | 11 (Configurable for gain, offset, and filtering) |

| Trimmer Resistors | 4 (Adjustable for signal calibration) |

| Connectors | 1x 20-pin, 1x 34-pin ribbon cable connectors |

| Isolation | 500 V DC (Channel-to-Ground) |

| Operating Temperature | -20°C to +70°C |

| Dimensions | 9.5 x 6.5 x 1.0 inches (241 x 165 x 25 mm) |

| Weight | Approximately 0.9 kg |

Key Features and Advantages

Precision Signal Conditioning: The GE DS3800HAFAID provides high-fidelity analog signal amplification with adjustable gain (0–100x) and offset correction, ensuring accurate representation of sensor data in control loops. Its trimmer resistors allow on-board calibration without external tools, reducing setup time.

Modular Compatibility: Designed for GE’s Mark IV Speedtronic platform, the module integrates seamlessly with other DS3800 series components (e.g., DS3800HACB address cards and DS3800HAIA analog conversion boards), enabling scalable control system configurations.

Rugged Industrial Design: With a dust-resistant enclosure and wide temperature range, the GE DS3800HAFAID withstands extreme conditions common in power plants, refineries, and steel mills. Its retention levers and modular connectors ensure secure mounting and vibration resistance.

Diagnostic Capabilities: Built-in test points and EEPROM support facilitate real-time monitoring of signal integrity and firmware updates, enabling predictive maintenance and compliance with ISO 13374 standards for condition-based monitoring.

Hot-Swap Functionality: The module supports in-service replacement, allowing maintenance without system shutdown. This feature is critical for minimizing downtime in continuous-process industries.

Application Areas

The GE DS3800HAFAID is widely deployed in industries requiring precise analog signal processing:

- Power Generation: Controls turbine speed, fuel flow, and temperature in gas and steam turbines, ensuring optimal efficiency and grid stability.

- Oil and Gas: Manages pressure and flow signals in upstream drilling rigs, midstream pipelines, and downstream refineries, supporting critical safety interlocks.

- Metallurgy: Regulates furnace temperature and rolling mill torque in steel production, maintaining product quality and reducing energy consumption.

- Water Treatment: Monitors pH, conductivity, and level sensors in wastewater treatment plants, enabling automated chemical dosing and process optimization.

- Marine Propulsion: Integrates with shipboard turbine control systems to manage engine performance and emissions compliance.

In each application, the GE DS3800HAFAID bridges the gap between analog sensors and digital control systems, ensuring seamless data flow and reliable operation.

Related Products

DS3820DMCB1 – GE CIRCUIT BOARD in Stock Buy | Repair

DS3820DMVB1 – GE CIRCUIT BOARD in Stock Buy | Repair

DS3820AISA – GE CIRCUIT BOARD TURBINE CONTROL

ds3820aira – analog i/o module

DS3820AIQA – GE CIRCUIT BOARD MARK IV

DS3820AIPA – Analog I/O Module

ds3800xvia1a1 – voltage indicator ge mark iv

DS3800NPPB1L1H Power Supply Board – Mark IV

Installation and Maintenance

Installation Preparation:

Before installing the GE DS3800HAFAID, ensure the Mark IV system is powered down and grounded. Align the module with the backplane connectors and secure it using the retention levers. Connect ribbon cables to the 20-pin and 34-pin connectors after mounting to avoid stress-induced damage. Verify jumper settings match the application requirements (e.g., gain, filter cutoff frequency) using GE’s official documentation.

Before installing the GE DS3800HAFAID, ensure the Mark IV system is powered down and grounded. Align the module with the backplane connectors and secure it using the retention levers. Connect ribbon cables to the 20-pin and 34-pin connectors after mounting to avoid stress-induced damage. Verify jumper settings match the application requirements (e.g., gain, filter cutoff frequency) using GE’s official documentation.

Maintenance Recommendations:

Regularly inspect the GE DS3800HAFAID for loose connections, corrosion, or physical damage. Use a calibrated multimeter to test trimmer resistor adjustments and monitor signal integrity via the board’s test points. Replace worn ribbon cables promptly to prevent signal degradation. For firmware updates, utilize GE’s programming tools to upload the latest EEPROM image, ensuring compatibility with system software revisions.

Regularly inspect the GE DS3800HAFAID for loose connections, corrosion, or physical damage. Use a calibrated multimeter to test trimmer resistor adjustments and monitor signal integrity via the board’s test points. Replace worn ribbon cables promptly to prevent signal degradation. For firmware updates, utilize GE’s programming tools to upload the latest EEPROM image, ensuring compatibility with system software revisions.

Product Assurance

GE guarantees the GE DS3800HAFAID with a 1-year warranty covering defects in materials and workmanship. Our global service network offers 24/7 technical support, including remote diagnostics and on-site repairs for critical failures. All modules undergo rigorous testing to meet ISO 9001 and UL standards, ensuring consistent performance in demanding environments. With guaranteed stock availability and a 3-day delivery time after payment, we minimize downtime during replacements, supporting your mission-critical operations.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com