Description

GE DS3800HAFA1B1D Speedtronic Mark IV Regulator Board

Product Overview

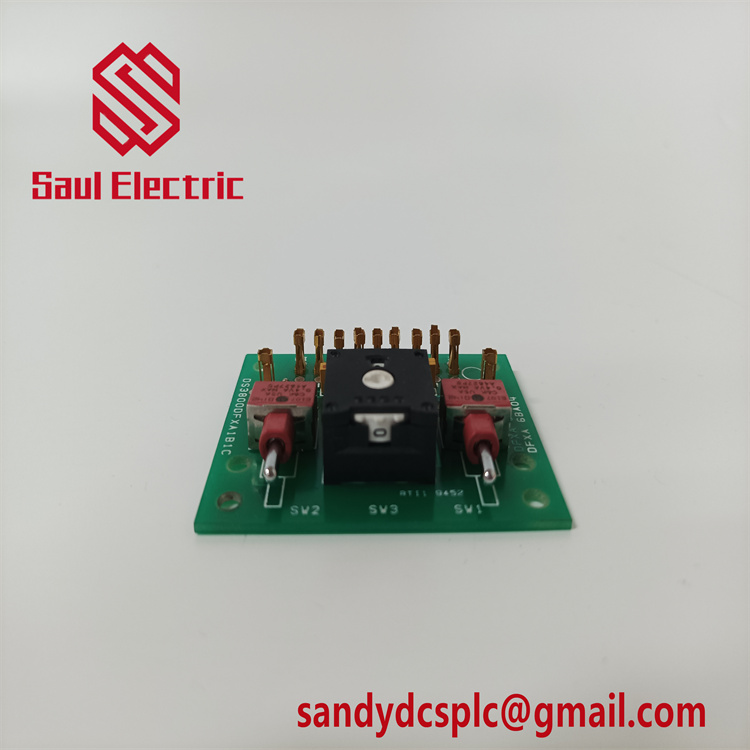

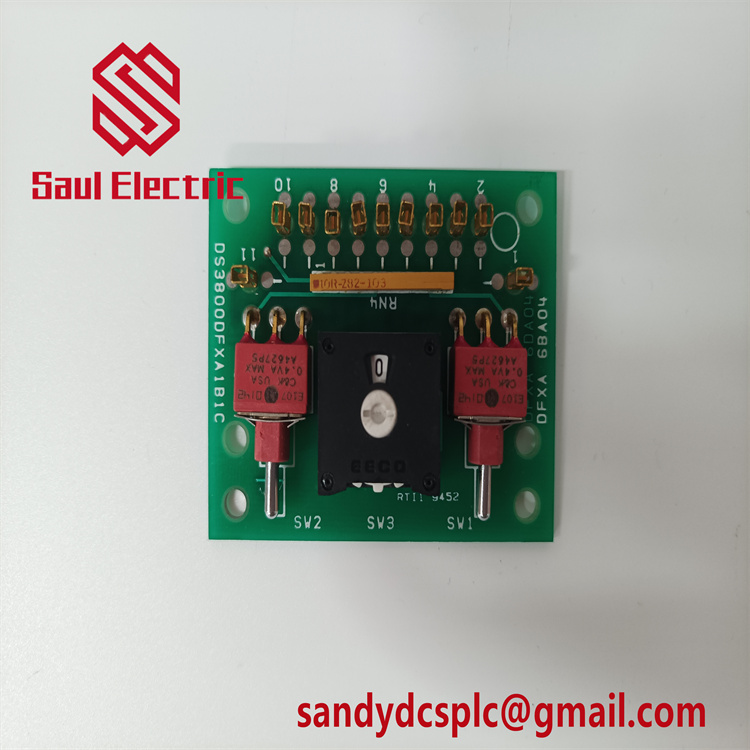

The GE DS3800HAFA1B1D is a high-performance regulator board designed for the GE Speedtronic Mark IV gas turbine control system. As a critical component of the Mark IV platform, this board serves as the interface between the turbine’s control logic and field devices, ensuring precise regulation of fuel flow, speed, and load in industrial power generation and oil & gas applications.

Engineered to handle real-time control signals, the DS3800HAFA1B1D integrates analog and digital processing capabilities to maintain stable turbine operation under varying conditions. It features a modular design with 11 jumpers and two connectors (20-pin and 34-pin) for flexible configuration, allowing users to adapt the board to specific turbine models and operational requirements. By combining advanced signal conditioning with rugged construction, the DS3800HAFA1B1D ensures reliable performance in harsh environments, including offshore platforms and high-temperature industrial settings.

Compliant with GE’s rigorous quality standards, the DS3800HAFA1B1D is backward-compatible with legacy Mark IV systems while supporting seamless integration with modern automation networks. Its role in the control loop includes monitoring sensor inputs (e.g., temperature, pressure), executing control algorithms, and providing diagnostic feedback to operators. This board is widely adopted in power plants, refineries, and marine propulsion systems, where uninterrupted turbine operation is essential for maximizing uptime and reducing maintenance costs.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE DS3800HAFA1B1D |

| Manufacturer | General Electric (GE) |

| Product Type | Regulator Board (Gas Turbine Control) |

| Input Signal Range | ±10 Vdc (analog), 5 Vdc (digital) |

| Power Supply | 24 Vdc ±10% |

| Weight | 1.2 lb (0.54 kg) |

| Physical Dimensions | 10.0 x 6.5 x 1.5 inches (25.4 x 16.51 x 3.81 cm) |

| Connector Type | 20-pin and 34-pin modular connectors |

| Operating Temperature | 0°C to +50°C (ambient) |

| Storage Temperature | -20°C to +70°C |

| Vibration Resistance | 5 g (10–2000 Hz) |

| Shock Resistance | 50 g (11 ms duration) |

| Compliance | IEEE 1149.1 (JTAG), UL 508, CSA C22.2 No. 142 |

Key Features and Advantages

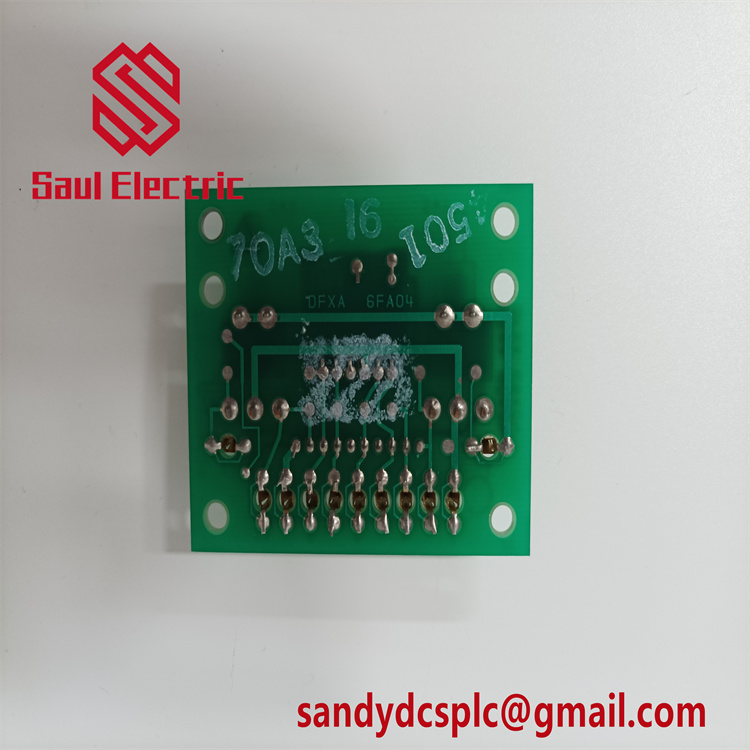

Rugged Design: The DS3800HAFA1B1D is built to withstand extreme conditions, including high vibrations and temperature fluctuations, making it suitable for harsh industrial environments. Its metal casing and conformal coating protect against dust, moisture, and corrosive gases.

Flexible Configuration: With 11 jumpers and configurable input/output channels, the board allows users to tailor its functionality to specific turbine models. This adaptability reduces the need for custom hardware modifications, streamlining installation and maintenance processes.

High-Speed Processing: The board’s integrated microprocessor ensures rapid signal conditioning and control algorithm execution, enabling real-time adjustments to turbine parameters such as fuel flow and speed. This capability is critical for maintaining stability during load changes or transient events.

Diagnostic Capabilities: The DS3800HAFA1B1D includes built-in self-test (BIST) features that continuously monitor internal components for faults. Fault codes are communicated via the board’s digital interface, facilitating quick troubleshooting and minimizing downtime.

Legacy Compatibility: Designed for the Mark IV system, the DS3800HAFA1B1D ensures seamless integration with existing GE Speedtronic infrastructure, providing a cost-effective upgrade path for aging control systems.

Applications

The GE DS3800HAFA1B1D is primarily used in gas turbine control systems across industries requiring reliable power generation and process control:

- Power Generation: Optimizing the operation of industrial gas turbines in power plants to ensure stable electricity production and grid synchronization.

- Oil & Gas: Regulating fuel flow and turbine speed in offshore platforms and refineries to maintain efficient hydrocarbon processing.

- Marine Propulsion: Controlling marine gas turbines for propulsion systems, ensuring smooth operation in high-stress maritime environments.

- Industrial Manufacturing: Monitoring and adjusting turbine performance in large-scale manufacturing facilities, such as chemical plants and steel mills.

In each application, the DS3800HAFA1B1D plays a pivotal role in maintaining turbine efficiency, reducing emissions, and extending equipment lifespan through precise control and predictive diagnostics.

Related Products

- GE DS3800HIOA1B1D Input Isolator Board: Provides signal isolation for analog and digital inputs, complementing the DS3800HAFA1B1D’s control functions.

- GE DS3800HDDD Digital Drive Module: Manages turbine drive systems, often used alongside the DS3800HAFA1B1D in complex control loops.

- GE DS3800HARA1B1C Regulator Board: A predecessor model with similar functionality, offering compatibility for retrofitting legacy systems.

- GE Mark IV Power Supply Module: Ensures stable power delivery to the DS3800HAFA1B1D and other Mark IV components.

- GE ControlST Software Suite: Enables configuration, monitoring, and diagnostics of the DS3800HAFA1B1D and the broader Mark IV system.

Installation and Maintenance

Installation Preparation:

Before installing the DS3800HAFA1B1D, verify compatibility with the Mark IV control system and ensure the rack is properly grounded. The board should be seated securely in the rack slot, with connectors tightened to prevent vibration-induced loosening. Signal cables must be routed away from power lines to minimize electromagnetic interference.

Before installing the DS3800HAFA1B1D, verify compatibility with the Mark IV control system and ensure the rack is properly grounded. The board should be seated securely in the rack slot, with connectors tightened to prevent vibration-induced loosening. Signal cables must be routed away from power lines to minimize electromagnetic interference.

Maintenance Recommendations:

Regularly inspect the board for physical damage, loose connections, or signs of corrosion. Clean dust and debris from the surface using a static-free cloth. Perform firmware updates as recommended by GE to access new features and bug fixes. Calibrate analog inputs annually using a precision voltage source to maintain measurement accuracy.

Regularly inspect the board for physical damage, loose connections, or signs of corrosion. Clean dust and debris from the surface using a static-free cloth. Perform firmware updates as recommended by GE to access new features and bug fixes. Calibrate analog inputs annually using a precision voltage source to maintain measurement accuracy.

Product Assurance

GE guarantees the DS3800HAFA1B1D with a 1-year warranty covering defects in materials and workmanship. This commitment is supported by GE’s global network of certified technicians, who provide 24/7 technical support and rapid replacement services. Customers also benefit from access to GE’s lifecycle management programs, which include system audits, hardware upgrades, and customized training to optimize the DS3800HAFA1B1D’s performance. By combining robust engineering with comprehensive support, GE ensures the DS3800HAFA1B1D delivers long-term reliability for critical turbine control applications.

-

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com