Description

GE DS3800DCMCICIC: Advanced Digital Control Module for Industrial Automation

Product Overview

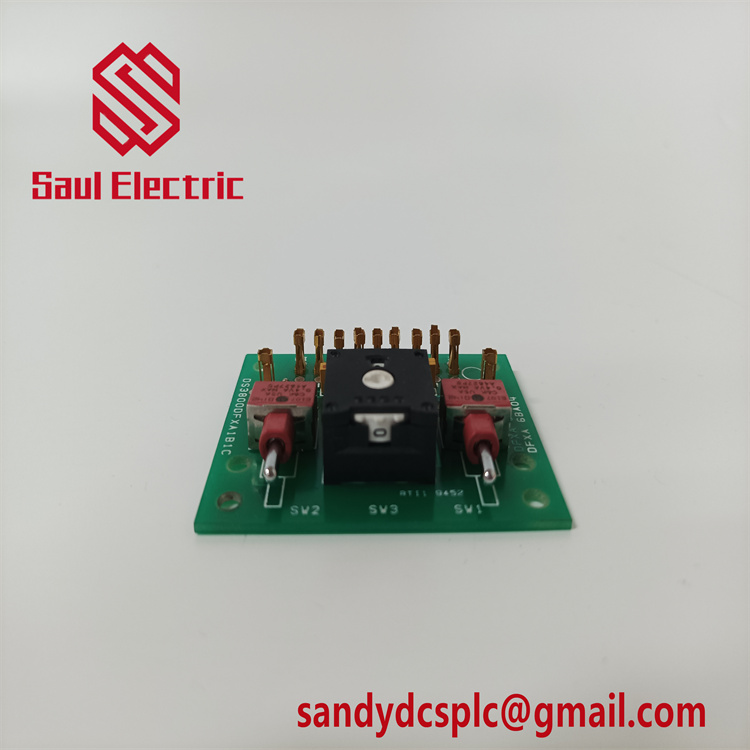

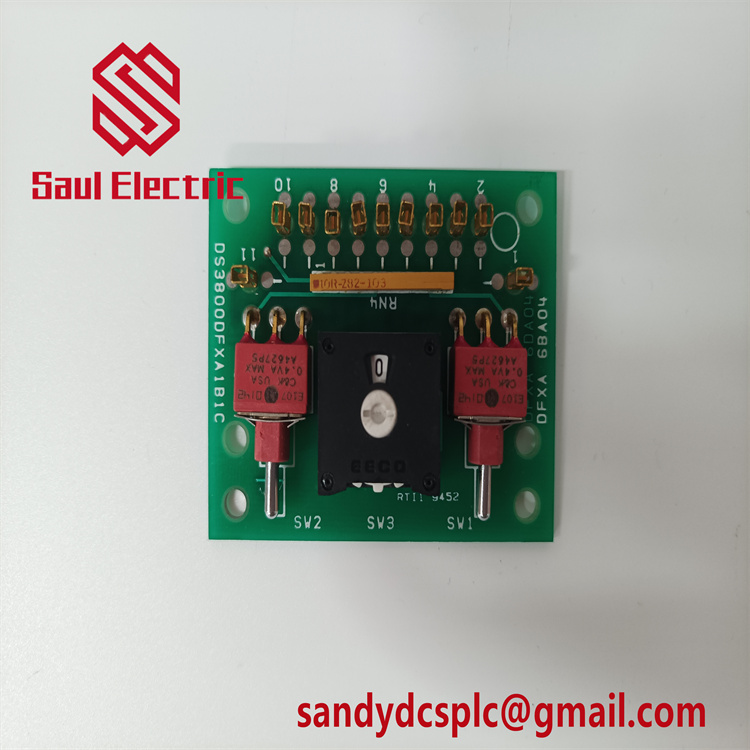

The GE DS3800DCMCICIC is a high-performance digital control module designed for GE’s Speedtronic Mark IV gas turbine control system. As a critical component of the Mark IV platform, this module serves as the backbone for multi-channel signal processing and distributed control in industrial power generation, oil & gas, and marine propulsion applications. Built on GE’s legacy of rugged reliability, the DS3800DCMCICIC integrates seamlessly with existing Mark IV infrastructure to manage real-time data exchange between turbine sensors, actuators, and higher-level control systems, ensuring precise regulation of processes like fuel flow, temperature, and speed.

Featuring a modular design with redundant communication pathways, the DS3800DCMCICIC supports both analog and digital signal conditioning, making it ideal for environments requiring high accuracy and fault tolerance. Its 13-pin I/O connectors and ribbon cable interface enable secure data transmission, while built-in diagnostics and fail-safe mechanisms minimize downtime by detecting anomalies and triggering automatic corrective actions . With compatibility across GE’s Mark IV system, this module offers a cost-effective upgrade path for legacy installations, combining modern control capabilities with backward compatibility.

In industrial settings, the DS3800DCMCICIC acts as a bridge between field devices and the central control unit, processing sensor inputs to generate actionable commands for actuators. Its wide operating temperature range (-20°C to +60°C) and corrosion-resistant aluminum casing ensure reliable performance in harsh conditions, from offshore platforms to high-vibration power plants. By leveraging GE’s proprietary control algorithms, the module optimizes turbine efficiency, reduces maintenance costs, and enhances overall system uptime.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE DS3800DCMCICIC |

| Manufacturer | General Electric (GE) |

| Product Type | Digital Control Module (DCM) with Signal Conditioning |

| Input Voltage | 24V DC ±10% (standard for Mark IV systems) |

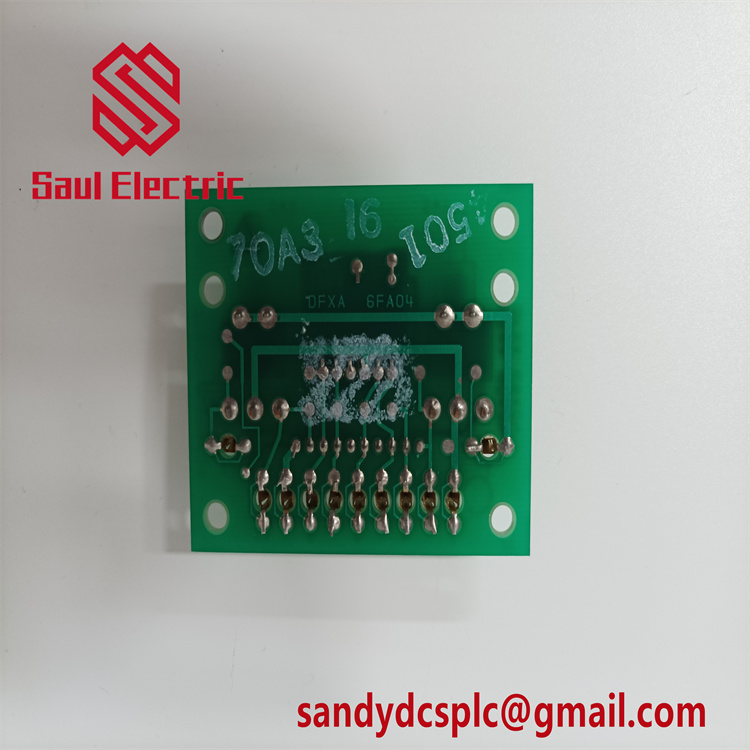

| Physical Dimensions | 175 mm x 100 mm x 30 mm (6.9 x 3.9 x 1.2 inches) |

| Weight | 0.5 kg (1.1 lbs) |

| Connector Type | 2 x 13-pin I/O connectors, 1 x ribbon cable interface |

| Communication Protocols | RS-485, Modbus RTU (inferred from Mark IV standards) |

| Operating Temperature | -20°C to +60°C |

| Humidity Range | 5% to 95% non-condensing |

| Redundancy Support | Dual-channel failover for critical applications |

| Compliance | UL 508, CE, ISO 9001 |

| Adjustment Features | Trimmer resistors, jumper switches for configurable signal thresholds |

Key Features and Advantages

Rugged Reliability: Built with a corrosion-resistant aluminum alloy casing and conformal coating, the DS3800DCMCICIC withstands extreme temperatures, moisture, and electromagnetic interference, ensuring continuous operation in challenging industrial environments. Its redundant communication pathways and built-in diagnostics automatically detect faults and switch to backup channels, minimizing downtime .

Precision Signal Processing: The module supports analog-to-digital (ADC) and digital-to-analog (DAC) conversion, enabling real-time monitoring and control of turbine parameters such as pressure, temperature, and rotational speed. Trimmer resistors and jumpers allow field technicians to fine-tune signal thresholds for optimal performance .

Modular Integration: Designed for GE’s Mark IV rack-mounted architecture, the DS3800DCMCICIC interfaces seamlessly with other Mark IV components (e.g., DS3800NFCF firing circuit boards and DS3800DECA excitation control modules), simplifying system expansion and maintenance. Its compact form factor ensures space-efficient installation in control cabinets .

Wide Compatibility: Backward compatible with legacy Mark IV systems, the DS3800DCMCICIC offers a cost-effective upgrade path without requiring full infrastructure replacement. It supports standard industrial protocols like RS-485 and Modbus RTU, facilitating integration with third-party systems .

Enhanced Safety: The module includes overvoltage and overcurrent protection mechanisms, automatically shutting down non-critical functions to prevent damage during power surges. This proactive safety design aligns with GE’s commitment to industrial hazard mitigation .

Applications

The GE DS3800DCMCICIC excels in mission-critical industrial scenarios requiring precise, reliable control:

- Power Generation: Managing turbine speed, fuel injection, and exhaust temperature in gas-fired power plants, ensuring stable grid synchronization and load shedding.

- Oil & Gas: Coordinating compressor stations and offshore platforms by integrating sensor data from pressure transducers, flow meters, and environmental monitors.

- Marine Propulsion: Optimizing propulsion systems by regulating turbine speed and load in real-time, supporting dynamic adjustments for varying sea conditions.

- Industrial Manufacturing: Controlling turbine-driven processes in chemical plants and steel mills, ensuring consistent power supply and minimizing production interruptions.

- Renewable Energy: Complementing wind turbine control systems by managing power conversion and grid integration for stable energy output.

Related Products

DS3800HCMB1C1C – In Stock Now | Ready To Ship – Call Us

GE Dual Communications Control Board DS3800HCMA

General Electric DS3800HAIC1A1A PC Board

GE Regulator Board DS3800HAIC1D1B

GE Regulator Board DS3800HAIC1B1A

General Electric DS3800HAFA1D1E

GENERAL ELECTRIC DS3800HAFA1B1D

GE DS3800HAFA | In Stock Now | Buy, Repair, Exchange From

Installation and Maintenance

Installation Preparation:

Verify compatibility with Mark IV racks and ensure proper grounding. Align the 13-pin connectors and ribbon cable with mating ports on the motherboard (e.g., DS3800DECA1B1B1) and secure them using retention latches. Route signal cables away from high-voltage lines to minimize EMI. Conduct a power integrity test to confirm 24V DC supply stability before powering up the module.

Verify compatibility with Mark IV racks and ensure proper grounding. Align the 13-pin connectors and ribbon cable with mating ports on the motherboard (e.g., DS3800DECA1B1B1) and secure them using retention latches. Route signal cables away from high-voltage lines to minimize EMI. Conduct a power integrity test to confirm 24V DC supply stability before powering up the module.

Maintenance Recommendations:

Inspect trimmer resistor settings annually using a calibrated multimeter to ensure accuracy. Clean dust and debris from the board’s surface with a static-free cloth. Perform firmware updates via GE’s proprietary software to access bug fixes and new features. In high-vibration environments, check connector tightness quarterly and retorque mounting screws as needed.

Inspect trimmer resistor settings annually using a calibrated multimeter to ensure accuracy. Clean dust and debris from the board’s surface with a static-free cloth. Perform firmware updates via GE’s proprietary software to access bug fixes and new features. In high-vibration environments, check connector tightness quarterly and retorque mounting screws as needed.

Product Assurance

GE guarantees the DS3800DCMCICIC with a 1-year warranty covering defects in materials and workmanship. Third-party suppliers like AX Control and World of Controls offer refurbished units with extended warranties (e.g., 3-year repair coverage) for cost-conscious customers. GE’s global support network provides 24/7 technical assistance, while authorized distributors ensure same-day shipping for urgent replacements. With its robust design and compatibility, the DS3800DCMCICIC delivers long-term value and peace of mind in industrial automation systems.

-

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com