Description

Product Overview

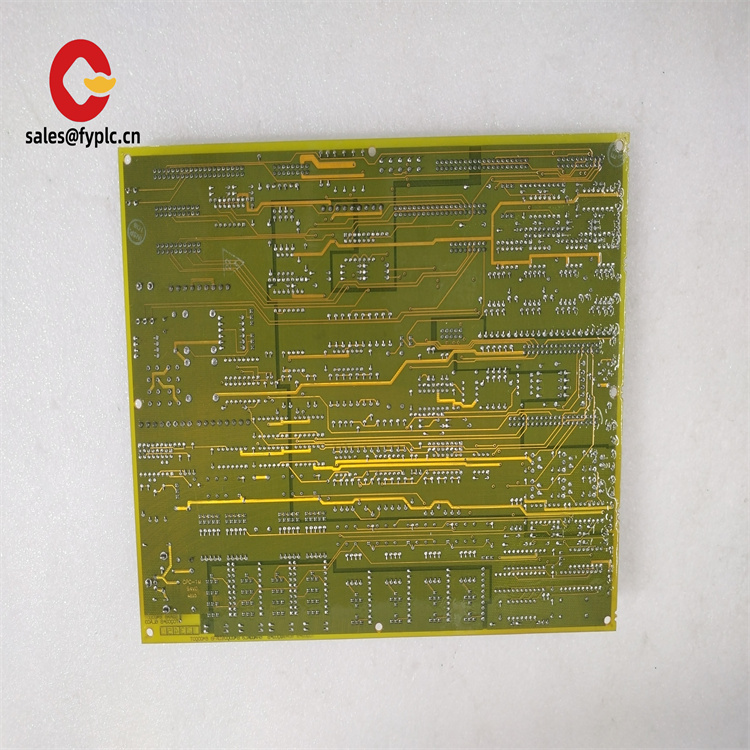

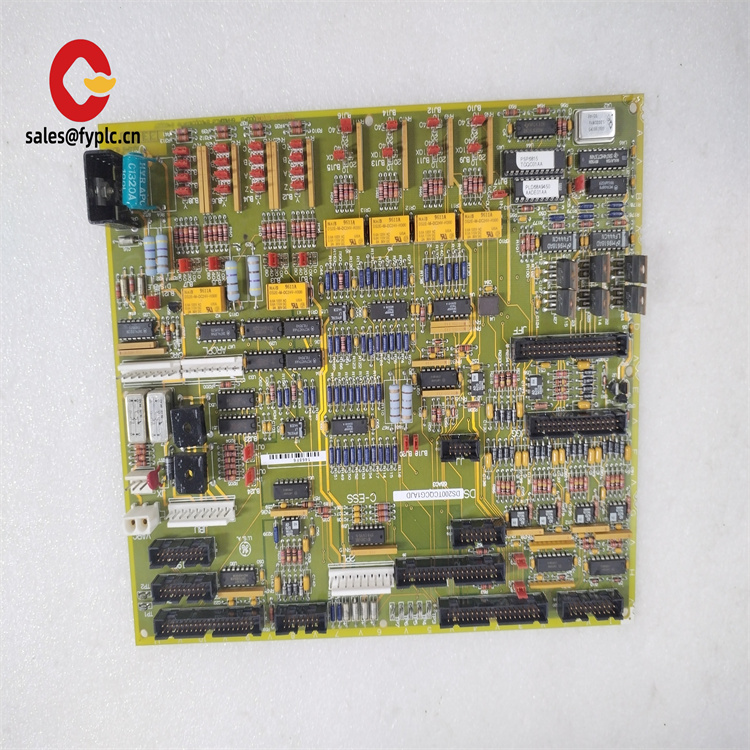

The GE DS200TCTGGIAEE is a Turbine Control Trip Board engineered for GE’s Mark V Speedtronic turbine control system, serving as a critical component in steam turbine protection and trip control applications. Designed for industrial automation and power generation, this module belongs to the legacy DS200 series, specifically optimized for executing emergency shutdowns, overspeed protection, and diagnostic testing in mission-critical environments .

As the master trip circuit within the Mark V system, the GE DS200TCTGGIAEE monitors turbine speed and activates protective measures during critical failures, such as excessive vibration or temperature deviations. It features dual primary trip relays (PTR1 & PTR2) and three emergency trip relays (ETR1 & ETR2), which trigger shutdowns if predefined thresholds are exceeded. The module also includes auxiliary control outputs for solenoid valves, enabling comprehensive testing of safety mechanisms like oil test and mechanical lockout functions .

Key functions include electrical and mechanical overspeed testing (both online and offline), ensuring compliance with safety standards, as well as TMR cross trip testing to verify the integrity of the triple modular redundancy (TMR) architecture. This redundancy ensures continuous operation even if one channel fails, making it ideal for high-reliability applications in power plants and offshore platforms .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200TCTGGIAEE |

| Manufacturer | GE (General Electric) |

| Product Type | Turbine Control Trip Board |

| Series | Mark V Speedtronic |

| Input Voltage | 24V DC ±10% |

| Redundancy | Triple Modular Redundancy (TMR) |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 3U form factor (100 mm x 160 mm) |

| Weight | ~1.54 kg |

| Terminals | 154 (77 per block via TB1/TB2) |

| Connectors | 3 x 34-pin, 2 x 16-pin |

| Protection Class | IP20 |

Main Features and Advantages

High-Reliability Protection:

The TMR architecture ensures fault tolerance by maintaining operation even if one channel fails, critical for power plants and offshore platforms. The module’s PCB coating protects against dust, moisture, and electromagnetic interference (EMC), ensuring long-term durability in harsh industrial environments .

Comprehensive Testing Capabilities:

Supports 10+ test scenarios, including electrical overspeed trip tests and mechanical trip piston tests, to validate turbine safety mechanisms. Diagnostic LEDs and jumper configurations simplify troubleshooting, reducing downtime during maintenance .

Legacy Compatibility:

Designed for Mark V systems, the GE DS200TCTGGIAEE interfaces seamlessly with other DS200 modules like the DS200TBQBG1ACB analog terminal board and DS200TCEAG1BSF emergency overspeed board, enabling scalable and integrated control solutions .

Industrial-Grade Durability:

Operates reliably in extreme conditions (-20°C to +60°C) with IP20 protection, making it suitable for high-vibration environments in power generation, oil & gas, and heavy industry. Its robust design ensures minimal maintenance and extended service life .

Application Areas

Power Generation:

Critical for steam turbine control systems in coal-fired and combined-cycle power plants, the GE DS200TCTGGIAEE ensures safe startup, load regulation, and emergency shutdowns. It monitors turbine speed and activates protective measures to prevent catastrophic failures during power generation .

Oil & Gas:

Used in offshore platforms and refineries to protect compressor and pump systems. The module’s TMR architecture and overspeed protection capabilities safeguard against equipment damage and operational disruptions in high-pressure environments .

Heavy Industry:

Supports steel mills and cement plants by integrating with PLCs and robotic systems for real-time process control. Its diagnostic capabilities enable predictive maintenance, optimizing production efficiency and reducing downtime .

Related Products

DS3800HCMB1C1C – In Stock Now | Ready To Ship – Call Us

GE Dual Communications Control Board DS3800HCMA

General Electric DS3800HAIC1A1A PC Board

GE Regulator Board DS3800HAIC1D1B

GE Regulator Board DS3800HAIC1B1A

General Electric DS3800HAFA1D1E

GENERAL ELECTRIC DS3800HAFA1B1D

GE DS3800HAFA | In Stock Now | Buy, Repair, Exchange From

Installation and Maintenance

Installation:

Mount the GE DS200TCTGGIAEE in a grounded VME rack with proper ventilation. Connect TB1/TB2 terminal blocks to field devices and 34-pin connectors to compatible Mark V modules. Follow GE’s GEH-6195D manual for wiring and configuration, ensuring compliance with safety standards .

Maintenance:

Inspect for loose connections and corrosion quarterly. Replace backup batteries (if applicable) every 5 years to maintain data integrity. Perform firmware updates via GE’s Control Builder software to ensure compatibility with system upgrades and enhance operational efficiency .

Product 保障

The GE DS200TCTGGIAEE is backed by a 1-year warranty covering defects in materials and workmanship. Authorized distributors provide technical support and repair services, ensuring rapid resolution of issues. With spot inventory and 3-day delivery after payment, customers can minimize downtime and maintain operational continuity.

For purchasing inquiries, contact authorized distributors like AX Control (+1-800-991-7026) or Direct Turbine Controls (201-244-6477). Always verify compatibility with your existing Mark V system before installation to ensure seamless integration and optimal performance .

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com