Description

Product Overview

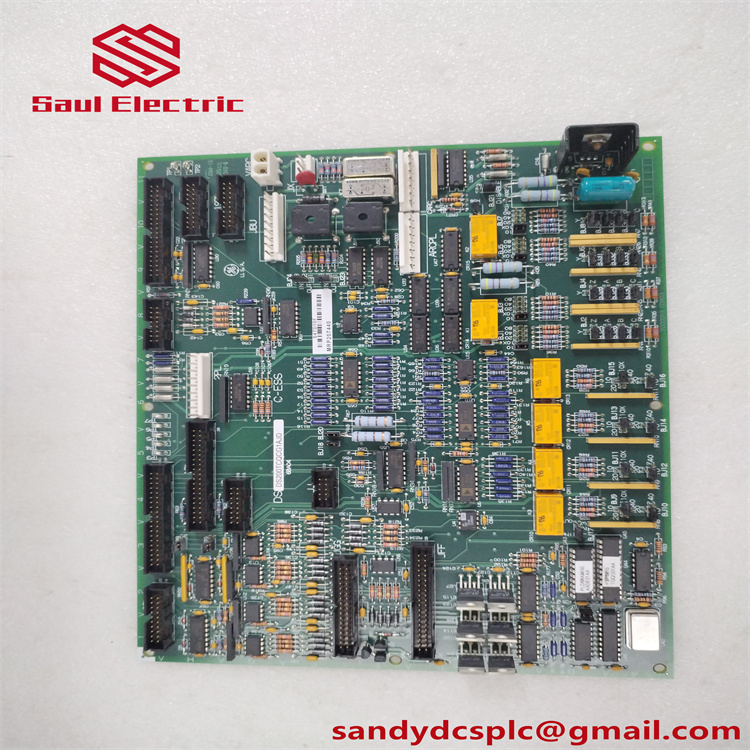

The GE DS200TCRAGIAAA is a high-reliability control module designed for industrial automation systems, specifically within GE’s Mark VIe turbomachinery control platform. As a critical component of turbine control systems, this module serves as a terminal connection and signal conditioning unit, enabling precise communication between various system components. The GE DS200TCRAGIAAA is engineered to manage analog and digital signals, ensuring seamless integration with other Mark VIe modules to facilitate real-time monitoring and control of turbine operations. Belonging to GE’s distinguished DS200 series, this module is valued for its durability in harsh industrial environments, offering robust performance in power generation, oil & gas, and heavy manufacturing sectors. Its design prioritizes signal integrity, fault tolerance, and ease of maintenance, making it an essential asset for maintaining operational efficiency in critical infrastructure systems.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200TCRAGIAAA |

| Manufacturer | GE (General Electric) |

| Product Type | Turbine Control Terminal Module |

| Electrical Voltage | 24 VDC ±10% |

| Operating Temperature | -40°C to +70°C |

| Physical Dimensions | 178 mm x 102 mm x 76 mm |

| Weight | Approximately 1.2 kg |

| Communication Protocol | Serial (RS-485) and parallel interface support |

| Input/Output Channels | 16 configurable I/O channels |

| Mounting Type | Rack-mounted (compatible with standard 19-inch racks) |

| Protection Class | IP20 (indoor use) |

| Compliance Standards | CE, UL 508, CSA C22.2 No. 14 |

Main Features and Advantages

The GE DS200TCRAGIAAA stands out for its advanced signal conditioning capabilities, which ensure accurate data transmission and minimal interference in complex control systems. One key feature is its configurable I/O architecture, allowing users to adapt the module to specific application requirements, from analog voltage/current sensing to digital logic control. The module incorporates built-in diagnostic functions that continuously monitor operational health, reducing downtime through early fault detection. Its rugged construction withstands vibrations, electrical noise, and temperature fluctuations, making it suitable for harsh industrial settings. Additionally, the DS200TCRAGIAAA supports hot-swappable functionality, enabling maintenance or replacement without system shutdown. GE’s proprietary design ensures compatibility with the broader Mark VIe ecosystem, promoting seamless integration and simplified system expansion. This module’s reliability and performance make it a preferred choice for mission-critical applications where operational continuity is essential.

Application Areas

The GE DS200TCRAGIAAA is primarily used in turbine control systems across various industries. In power generation plants, it facilitates precise control of steam or gas turbines, optimizing energy production and grid stability. Within oil & gas facilities, the module supports compressor and pump control, ensuring efficient process flow and safety compliance. It is also integral to industrial machinery in manufacturing sectors, where it manages motor drives and process signals for automated production lines. The module’s adaptability makes it suitable for retrofitting older systems or integrating into new smart industrial setups. Its role in signal conditioning and terminal connection makes it critical for systems requiring high precision, such as combined cycle power plants, petrochemical refineries, and large-scale manufacturing complexes. By enabling reliable communication between control processors and field devices, the DS200TCRAGIAAA enhances overall system reliability and operational efficiency.

Related Products

DS3800HCMB1C1C – In Stock Now | Ready To Ship – Call Us

GE Dual Communications Control Board DS3800HCMA

General Electric DS3800HAIC1A1A PC Board

GE Regulator Board DS3800HAIC1D1B

GE Regulator Board DS3800HAIC1B1A

General Electric DS3800HAFA1D1E

GENERAL ELECTRIC DS3800HAFA1B1D

GE DS3800HAFA | In Stock Now | Buy, Repair, Exchange From

Installation and Maintenance

Installation 前准备: Ensure the installation environment meets the DS200TCRAGIAAA’s operational specifications, including temperature and voltage requirements. Prepare the rack mounting system with appropriate spacing to facilitate airflow. Verify all wiring connections match the module’s datasheet to avoid signal conflicts.

Maintenance 建议: Regularly inspect the module for physical damage or loose connections. Use diagnostic tools to monitor operating parameters and ensure no error codes are present. Clean the module’s exterior with a dry, static-free cloth to prevent dust accumulation. For optimal performance, schedule periodic system resets and firmware updates as recommended by GE. In the event of a fault, refer to the troubleshooting guide to identify and replace faulty components promptly.

Product Guarantee

The GE DS200TCRAGIAAA is backed by a 1-year warranty, ensuring protection against manufacturing defects. Our team provides comprehensive technical support, including installation guidance, troubleshooting assistance, and firmware update services. We commit to delivering prompt 售后服务,with genuine replacement parts available to maintain system integrity. Our quality assurance processes ensure each module undergoes rigorous testing before delivery, guaranteeing reliability and performance in demanding industrial applications.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com