Description

Product Overview

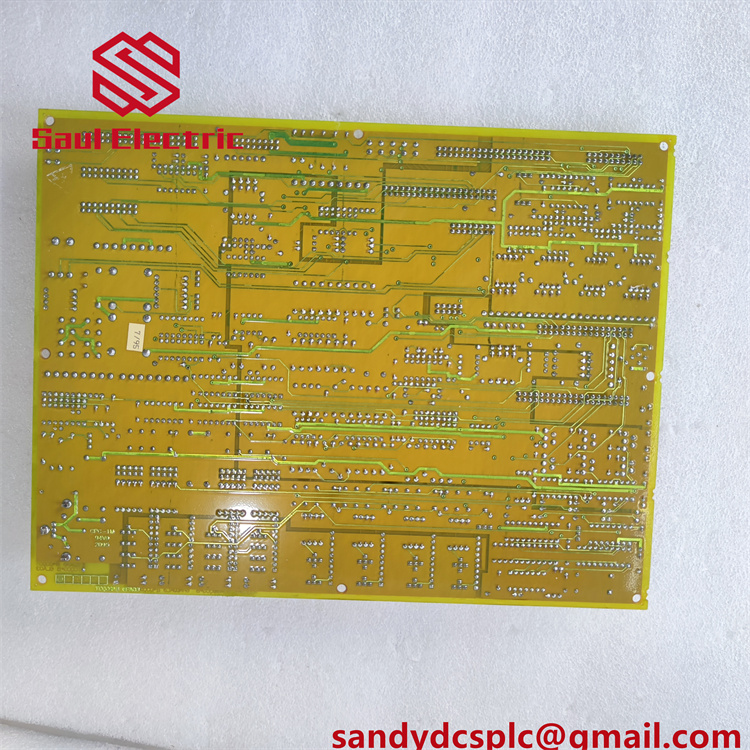

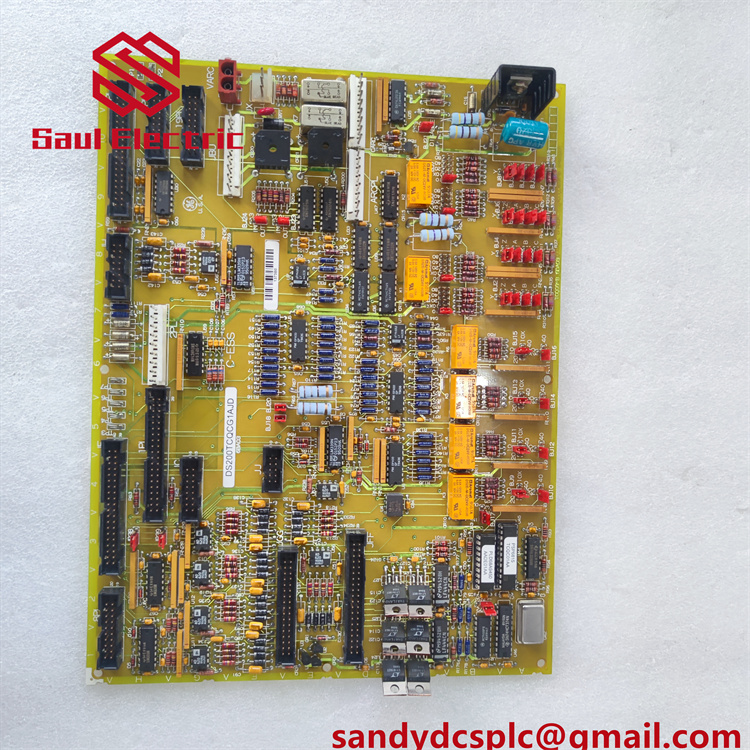

The GE DS200TCQCG1BGF is an Analog I/O Expander Board designed for GE’s Mark V series turbine control systems, serving as a critical component in industrial automation and power generation applications. Engineered to expand analog input/output (I/O) capabilities, this module supports precise signal conditioning and expansion for steam, gas, and wind turbines. With configurable jumpers and connectors, the DS200TCQCG1BGF integrates seamlessly with other Mark V modules to ensure reliable operation in mission-critical environments.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE DS200TCQCG1BGF |

| Manufacturer | GE (General Electric) |

| Product Type | Analog I/O Expander Board for Mark V Turbine Control Systems |

| Configuration | 24 jumpers, 3x 40-pin connectors (JFF, JE, 6PL), 3x 34-pin connectors, 1x 16-pin connector (JC) |

| Signal Handling | Supports analog input/output expansion for turbine control loops |

| Power Supply | Derived from Mark V rack power distribution (±15V DC, +5V DC) |

| Diagnostic Indicators | LED status indicators (factory-calibrated) |

| Operating Temperature | -40°C to +85°C (non-condensing) |

| Dimensions | 120mm (W) × 80mm (H) × 50mm (D) |

| Weight | 0.4 kg |

| Certifications | CE, UL 508, CSA C22.2 No. 14 |

| Compatibility | GE Mark V series drives (AC2000, DC2000, CB2000, ME2000, FC2000, EX2000) |

| Instruction Manual | GEI-100182B (Contactor Driver Board Manual, partially applicable) |

Main Features and Advantages

The GE DS200TCQCG1BGF excels in analog signal management, providing galvanic isolation and noise filtering for critical turbine control signals. Its 24 jumpers enable flexible configuration for different input/output ranges (e.g., 0–10V DC, 4–20mA), while the modular connector design supports seamless integration with other Mark V modules (e.g., DS200TCQAG1BHF analog I/O board). Key advantages include:

- Signal Expansion: Expands analog I/O capacity for turbine vibration monitoring, temperature sensing, and speed control loops.

- Rugged Construction: Conformal coating and EMI/RFI shielding protect against harsh environments, including offshore platforms and high-vibration settings.

- Hot-Swap Capability: Allows maintenance without system shutdown, minimizing downtime in power plants and industrial facilities.

- Proactive Diagnostics: LED indicators provide real-time status feedback on signal integrity and fault conditions.

Application Areas

The GE DS200TCQCG1BGF is widely deployed in industries requiring robust analog signal conditioning:

- Power Generation: Manages steam/gas turbine excitation systems, generator field control, and load regulation in utility-scale power plants.

- Oil & Gas: Supports compressor drive control, wellhead equipment monitoring, and process automation in offshore platforms and refineries.

- Industrial Automation: Expands analog I/O for robotic assembly lines, conveyor systems, and precision motion control in manufacturing facilities.

- Water/Wastewater Treatment: Integrates with pump control systems and filtration processes for closed-loop feedback.

Related Products

Installation and Maintenance

Installation Preparation:

- Mount the GE DS200TCQCG1BGF in a Mark V rack, securing it with captive screws.

- Connect analog signals to the 40-pin and 34-pin connectors (JFF, JE, 6PL) and ground the board per GEI-100182B guidelines.

- Configure jumpers based on the application (e.g., signal range, termination settings) using the GEI-100182B manual.

- Verify shielded cabling to minimize EMI interference.

Maintenance Recommendations:

- Weekly Checks: Monitor LED status and test point voltages using a multimeter.

- Quarterly Inspections: Inspect terminal connections for corrosion or looseness, especially in high-humidity environments.

- Annual Calibration: Verify signal conditioning accuracy using test points (e.g., REF A, +15V DC).

- Firmware Updates: Download the latest firmware from GE’s support portal to access performance optimizations.

Product Guarantee

The GE DS200TCQCG1BGF is backed by a 12-month warranty covering manufacturing defects, with optional extended warranties (up to 3 years) available for critical applications. GE’s global technical support team provides 24/7 assistance for troubleshooting, including remote diagnostics and on-site service. Replacement units are stocked in regional warehouses for expedited delivery (2–5 days), ensuring minimal operational disruption. The module undergoes rigorous testing to meet IEC 61131-2 and IEEE standards, ensuring long-term reliability in even the most demanding industrial environments.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com