Description

Product Overview

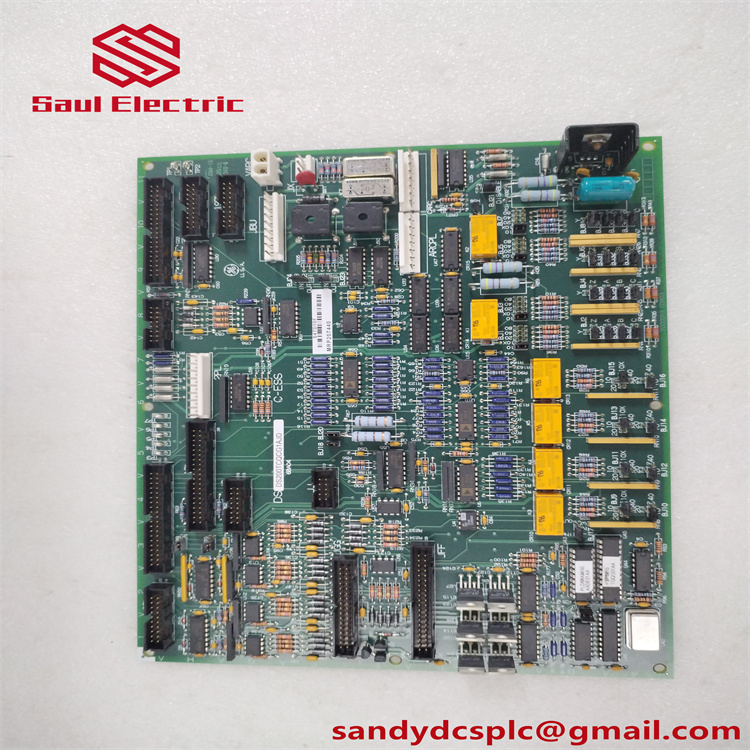

The GE DS200TCQCG1AHD is a Quadrature Encoder Interface Module designed for GE’s Mark V Speedtronic turbine control system, serving as a critical component for precision speed and position feedback in industrial automation. Belonging to the legacy DS200 series, this module processes high-frequency encoder signals from turbines, motors, and rotating equipment, enabling real-time monitoring and regulation in mission-critical environments.

As part of the Mark V system’s Digital I/O architecture, the GE DS200TCQCG1AHD interfaces with quadrature encoders to convert mechanical rotation into electrical pulse signals for the control processor. It features four independent encoder channels (A, B, Z phases) with configurable resolution up to 16 bits, supporting input frequencies up to 500 kHz. The module’s triple modular redundancy (TMR) ensures continuous operation even if one channel fails, making it essential for applications where encoder failure could lead to system instability, such as power generation and heavy manufacturing.

The AHD suffix denotes a specific hardware revision, likely incorporating enhanced vibration resistance and improved signal conditioning compared to previous variants. Its rugged design, with PCB coating for EMC protection and IP20 housing, ensures reliability in harsh conditions (-20°C to +60°C) with resistance to extreme vibrations and electromagnetic interference.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200TCQCG1AHD |

| Manufacturer | GE (General Electric) |

| Product Type | Quadrature Encoder Interface Module |

| Series | Mark V Speedtronic |

| Input Voltage | 24V DC ±10% |

| Encoder Channels | 4 (A, B, Z phases per channel) |

| Max. Input Frequency | 500 kHz |

| Resolution | Up to 16 bits (configurable) |

| Redundancy | Triple Modular Redundancy (TMR) |

| Operating Temp. | -20°C to +60°C |

| Storage Temp. | -40°C to +85°C |

| Physical Dimensions | 3U form factor (100 mm x 160 mm) |

| Weight | ~1.2 kg |

| Connectors | 2×34-pin, 1×16-pin |

| Vibration Resistance | 5-500 Hz, 2G (RMS) |

| Protection Class | IP20 |

Main Features and Advantages

Enhanced Vibration Tolerance:

The GE DS200TCQCG1AHD is engineered with upgraded mounting fixtures and PCB reinforcement, making it suitable for high-vibration environments (up to 2G RMS). This feature ensures stable encoder signal processing in applications like offshore drilling platforms or heavy machinery, where constant vibration could compromise performance.

Advanced Signal Conditioning:

Featuring revised signal amplification circuitry, the module minimizes noise and jitter in encoder signals, even at maximum input frequencies (500 kHz). This precision is critical for turbine speed governors, ensuring accurate feedback for load regulation and grid synchronization.

TMR Redundancy with Fault Isolation:

The triple modular redundancy architecture includes enhanced fault isolation logic, allowing the module to identify and isolate failed channels without disrupting overall operation. This improves system availability in safety-critical scenarios, such as emergency shutdown sequences.

Field-Upgradable Firmware:

Compatible with GE’s Control Builder software, the DS200TCQCG1AHD supports on-the-fly firmware updates, enabling users to deploy bug fixes or feature enhancements without system downtime. Diagnostic LEDs provide real-time status feedback for quick troubleshooting.

Application Areas

Power Generation:

In thermal and combined-cycle power plants, the GE DS200TCQCG1AHD monitors steam turbine speeds for grid synchronization, adjusting fuel valves in real time to maintain stable power output. Its vibration resistance makes it ideal for installation near turbine generators, where high-frequency vibrations are common.

Oil & Gas Extraction:

Offshore platforms and drilling rigs use this module to monitor compressor and pump speeds, enabling real-time adjustment of anti-surge valves. The TMR architecture ensures uninterrupted operation in harsh marine environments, where equipment failure could lead to safety hazards.

Heavy Machinery Manufacturing:

In steel mills and paper plants, the DS200TCQCG1AHD provides precise position feedback for rolling mills and conveyor systems. Its rugged design withstands the constant vibration from heavy machinery, ensuring consistent process control.

Aerospace Testing Facilities:

Used in jet engine test stands, the module processes high-speed encoder signals from rotational sensors, enabling accurate performance analysis under extreme conditions. Its EMC protection guards against interference from testing equipment.

Related Products

DS3800HCMB1C1C – In Stock Now | Ready To Ship – Call Us

GE Dual Communications Control Board DS3800HCMA

General Electric DS3800HAIC1A1A PC Board

GE Regulator Board DS3800HAIC1D1B

GE Regulator Board DS3800HAIC1B1A

General Electric DS3800HAFA1D1E

GENERAL ELECTRIC DS3800HAFA1B1D

GE DS3800HAFA | In Stock Now | Buy, Repair, Exchange From

Installation and Maintenance

Installation Preparation:

Mount the GE DS200TCQCG1AHD in a grounded VME rack using anti-vibration washers to minimize resonance. Connect shielded encoder cables to the 34-pin connectors, ensuring proper grounding to reduce electromagnetic interference. Use GE Control Builder software to configure encoder parameters (resolution, direction) and enable TMR redundancy.

Maintenance Recommendations:

- Quarterly Vibration Checks: Inspect mounting hardware for looseness in high-vibration environments.

- Annual Signal Calibration: Use built-in diagnostics via Control Builder to verify encoder signal accuracy and channel redundancy.

- Component Replacement: Replace backup batteries every 5 years to preserve configuration data. Periodically check connector pins for corrosion, especially in humid environments.

Product Warranty

GE guarantees the DS200TCQCG1AHD against defects in materials and workmanship for 1 year. Authorized distributors provide 24/7 technical support, including remote diagnostics and on-site repair services. With spot inventory and 3-day delivery after payment, customers can minimize downtime in critical operations. The module’s rugged design and compliance with industrial standards ensure long-term reliability in demanding applications.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com