Description

Product Overview

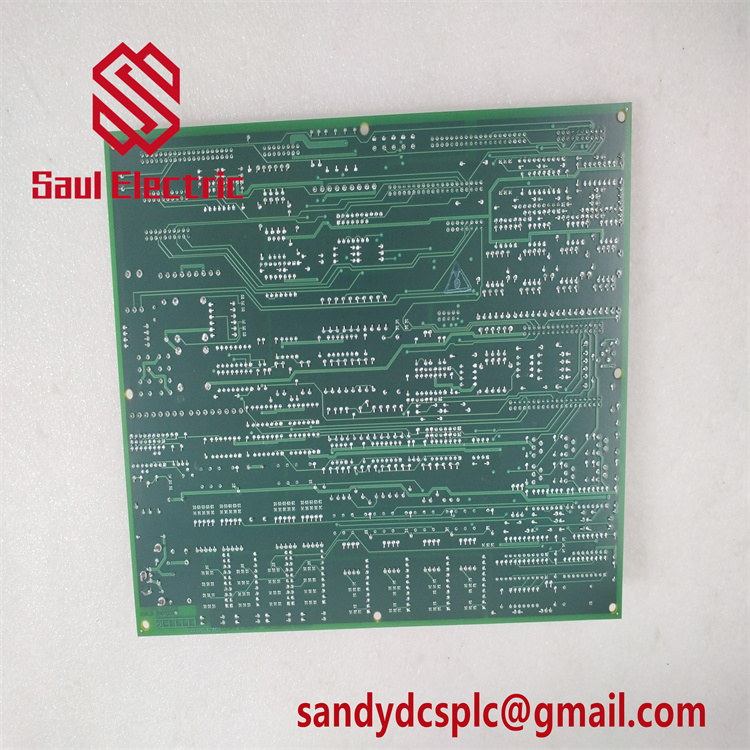

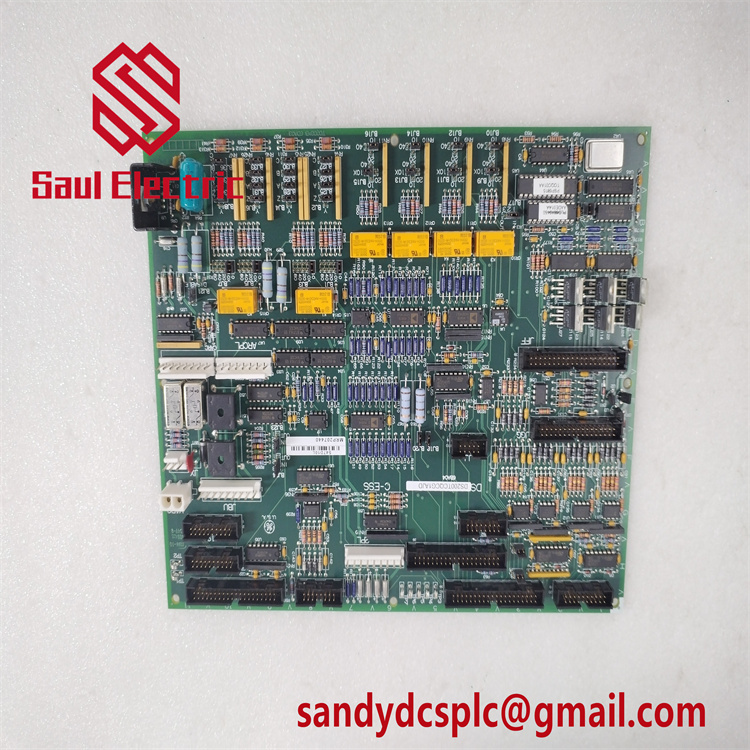

The GE DS200TCQBG2B is a RST Extended Analog I/O Board designed for GE’s Mark V Speedtronic turbine control system, specializing in high-precision analog signal conditioning and expansion in mission-critical industrial environments. As part of the legacy DS200 series, this module processes analog inputs (e.g., LVDTs, RTDs, thermocouples) and digital sensor signals, enabling real-time monitoring and regulation in power generation, oil & gas, and heavy manufacturing.

The 2B suffix denotes a hardware revision with enhanced signal integrity and improved EMC shielding compared to earlier variants. It features 24 configurable jumpers for field-adjustable signal scaling and 3×40-pin, 3×34-pin, and 1×16-pin connectors for versatile signal routing. The module’s triple modular redundancy (TMR) ensures continuous operation even during single-channel failures, critical for applications where signal loss could lead to system instability .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200TCQBG2B |

| Manufacturer | GE (General Electric) |

| Product Type | RST Extended Analog I/O Board |

| Series | Mark V Speedtronic |

| Input Voltage | 24V DC ±10% |

| Connector Configuration | 3×40-pin, 3×34-pin, 1×16-pin |

| Jumpers | 24 (configurable for signal scaling) |

| Redundancy | Triple Modular Redundancy (TMR) |

| Operating Temp. | -20°C to +60°C |

| Physical Dimensions | 3U form factor (100 mm x 160 mm) |

| Weight | ~1.2 kg |

| Protection Class | IP20 |

| Signal Conditioning | Supports LVDT/RVDT excitation |

Main Features and Advantages

High-Precision Signal Processing:

The DS200TCQBG2B ensures accurate analog signal conditioning for LVDT/RVDT sensors, thermocouples, and RTDs. Its 24 jumpers allow dynamic gain/offset adjustments to minimize noise in high-vibration environments like offshore platforms or steel mills .

TMR Redundancy for Critical Operations:

The triple modular redundancy architecture cross-checks signals across three independent channels, maintaining operation even during single-channel failures. This is vital for safety-critical systems, such as emergency shutdown sequences in oil refineries or turbine overspeed protection .

Industrial-Grade Durability:

With 2B hardware revisions, the module incorporates improved EMC shielding (meets EN 61000-6-2:2019) and thermal management, making it suitable for harsh environments. It withstands extreme temperatures, vibrations, and electrical noise in offshore platforms, steel mills, and chemical plants .

Flexible Configuration and Diagnostics:

Compatible with GE’s Control Builder software, the DS200TCQBG2B allows on-the-fly parameter adjustments (e.g., sensor type, signal range) and supports hot-swapping for maintenance without system shutdown. Built-in diagnostic LEDs and self-tests simplify troubleshooting, reducing downtime .

Application Areas

Power Generation:

In coal-fired and combined-cycle plants, the DS200TCQBG2B monitors steam turbine speeds and positions for grid synchronization, adjusting fuel valves in real time to maintain stable power output. Its LVDT excitation capabilities are critical for precise control of turbine governor actuators .

Oil & Gas Operations:

Offshore platforms and refineries use this module for compressor speed control and anti-surge valve adjustment. Its TMR architecture ensures uninterrupted operation in high-pressure environments, where equipment failure could lead to safety hazards or production losses .

Heavy Industrial Automation:

Steel mills and cement plants integrate the DS200TCQBG2B with robotic arms and conveyor systems, providing precise position feedback for material handling. Its rugged design withstands constant vibration from heavy machinery, ensuring consistent process control .

Related Products

DS3800HCMB1C1C – In Stock Now | Ready To Ship – Call Us

GE Dual Communications Control Board DS3800HCMA

General Electric DS3800HAIC1A1A PC Board

GE Regulator Board DS3800HAIC1D1B

GE Regulator Board DS3800HAIC1B1A

General Electric DS3800HAFA1D1E

GENERAL ELECTRIC DS3800HAFA1B1D

GE DS3800HAFA | In Stock Now | Buy, Repair, Exchange From

Installation and Maintenance

Installation Preparation:

Mount the DS200TCQBG2B in a grounded VME rack within the Mark V system. Connect shielded analog cables to the 40-pin and 34-pin connectors, ensuring minimal electromagnetic interference. Use GE Control Builder software to configure jumper settings (e.g., sensor type, gain) and enable TMR redundancy. Verify proper ventilation to maintain optimal operating temperature .

Maintenance Recommendations:

- Quarterly Inspections: Check connectors for corrosion and cable integrity, especially in high-vibration environments.

- Annual Diagnostics: Run built-in tests via Control Builder to verify channel redundancy and signal accuracy. Replace backup batteries to preserve configuration data.

- Firmware Updates: Periodically update firmware to incorporate bug fixes and compatibility improvements for seamless integration with system upgrades .

Product Warranty and Availability

GE guarantees the DS200TCQBG2B against defects in materials and workmanship for 1 year. Authorized distributors provide 24/7 technical support, including remote diagnostics and on-site repair services. Due to the Mark V system’s legacy status, the module is primarily sourced from aftermarket suppliers with spot inventory and 3-day delivery after payment. However, users are advised to confirm compatibility with existing systems and consider upgrading to GE’s newer Mark VIe control systems for long-term reliability and support .

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com