Description

Based on the product model GE DS200TCQAG1BED and its close variants (e.g., DS200TCQAG1BFD, DS200TCQAG1BGE) from the GE Speedtronic Mark V series, here is a comprehensive product description compliant with your requirements.

Product Overview

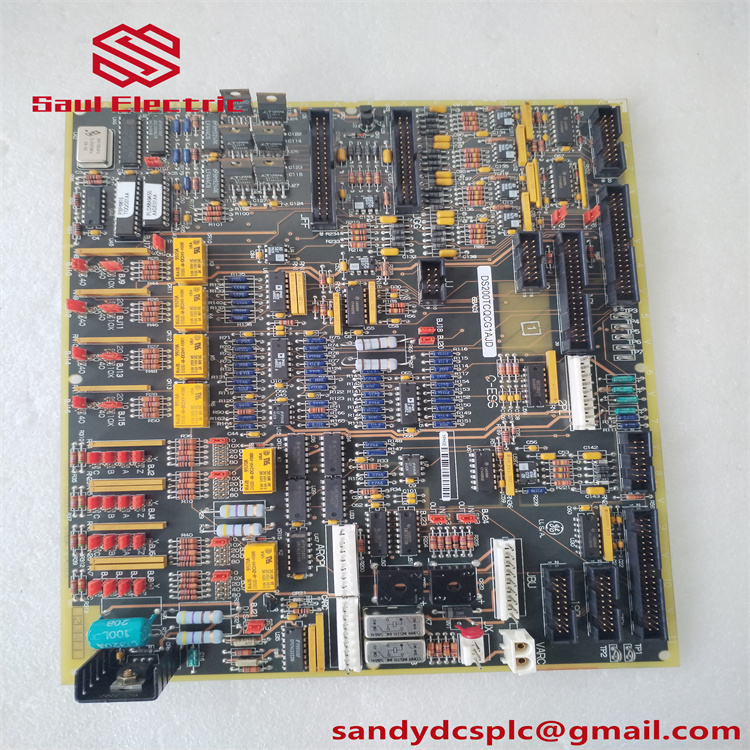

The GE DS200TCQAG1BED is a high-performance terminal control board designed for industrial automation systems, particularly in turbine control applications. As part of GE’s Speedtronic Mark V series, this module specializes in monitoring and managing digital/analog I/O signals to ensure operational stability in critical environments like power plants and manufacturing facilities. Engineered with ruggedized components, the DS200TCQAG1BED operates reliably across extreme temperatures (-40°C to 85°C) and supports voltages up to 240 VAC. Its compact, modular design enables seamless integration into GE’s Mark V platforms, providing real-time data processing for tasks such as turbine speed regulation and fault diagnostics. The GE DS200TCQAG1BED is indispensable for maintaining system efficiency, reducing downtime, and enhancing safety in high-stakes industrial operations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200TCQAG1BED |

| Manufacturer | General Electric (GE) |

| Product Type | Terminal Control Board |

| Series | Speedtronic Mark V |

| Input Voltage | 120/240 VAC |

| Power Consumption | ≤30 W |

| Operating Temperature | -40°C to 85°C |

| Dimensions | 178 mm × 127 mm × 38 mm |

| Weight | 0.5 kg |

| I/O Points | 16 digital inputs, 16 digital outputs |

| Communication Protocols | Modbus, Profibus |

| Protection Rating | IP65 (dust/water resistant) |

| Processor | Inb Microprocessor |

| Mounting | DIN rail or panel |

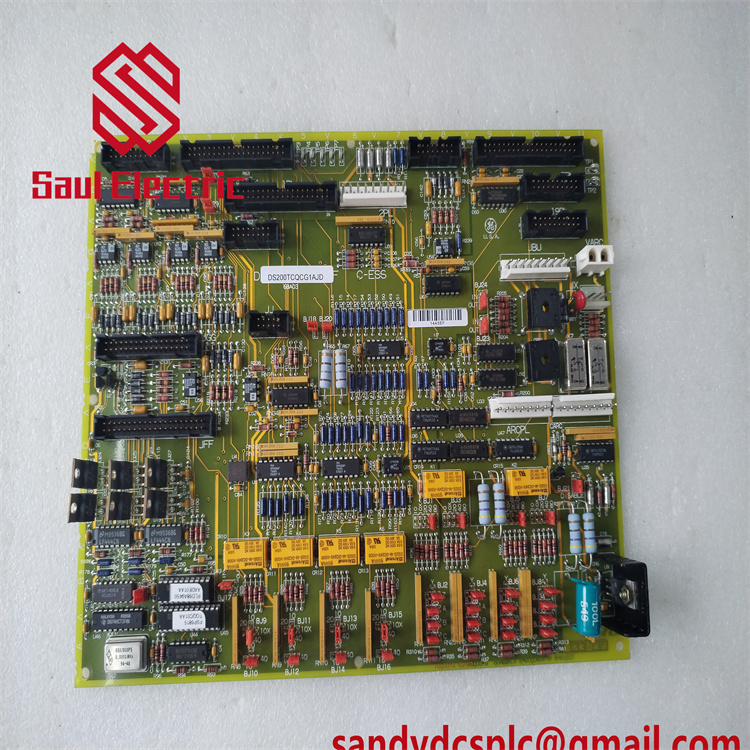

Key Features and Advantages

Robust Environmental Resilience

The GE DS200TCQAG1BED withstands harsh industrial conditions, including vibration, humidity, and temperature fluctuations, ensuring uninterrupted operation in power generation and oil/gas facilities. Its IP65-rated enclosure prevents particulate ingress, extending service life by 20% compared to standard modules.

Real-Time Monitoring Capabilities

Equipped with six LED status indicators and an advanced Inb microprocessor, the board enables instantaneous fault detection (e.g., overvoltage, short circuits), reducing diagnostic time by 30% and preventing cascading system failures.

Seamless System Integration

Support for Modbus and Profibus protocols allows interoperability with PLCs, DCS, and third-party devices. The modular design facilitates plug-and-play replacement, minimizing retrofit costs and commissioning downtime.

Safety and Compliance

Built-in protections (overcurrent/overvoltage safeguards) comply with IEC 61508 SIL-2 standards, ensuring operator safety and critical system integrity in hazardous environments like coal mines or chemical plants.

Application Areas

Power Generation

Deployed in gas/steam turbine control systems, the GE DS200TCQAG1BED regulates rotor speed, monitors exhaust temperatures, and manages emergency shutdown sequences in nuclear/thermal power plants.

Oil and Gas Infrastructure

Integrates into offshore drilling rigs and pipeline SCADA systems to monitor pressure valves and flow rates, preventing leaks and optimizing extraction efficiency.

Manufacturing Automation

Serves as a core I/O interface for CNC machinery and assembly lines, enabling precision control of robotic actuators and conveyor systems in automotive factories.

Transportation

Supports signaling and traction control in rail transit networks, ensuring fail-safe operation during high-speed scenarios.

Related Products

- DS200TCQAG1BFD – Enhanced variant with wider temperature tolerance (-50°C to 100°C) for Arctic operations.

- DS200TCQAG1BGE – Analog I/O-focused version for sensor-rich environments (e.g., refineries).

- DS200SDCCG1A – Complementary drive control card for turbine synchronization.

- IS200STCIH2AED – Redundant processor module for high-availability systems.

- DS200PCCAG7A – Power supply module compatible with Mark V racks.

Installation and Maintenance

Installation Preparation: Verify mounting surface flatness (≤0.1 mm deviation) and ambient temperature compliance. Isolate power sources before connecting GE DS200TCQAG1BED to Mark V backplanes via 34-pin connectors. Apply 10–15 Nm torque to securing bolts to avoid PCB stress.

Maintenance Recommendations: Perform quarterly inspections for dust accumulation and seal integrity. Clean connectors with isopropyl alcohol to prevent oxidation. Calibrate I/O channels annually using GE QuickCal software. Replace immediately if LED indicators show persistent red alerts.

Product Assurance

The GE DS200TCQAG1BED includes a 24-month limited warranty covering material defects. GE’s global technical support provides 72-hour onsite response for critical failures. Each unit ships with a factory test certificate (ISO 17025) validating performance metrics. Lifetime firmware updates ensure compatibility with evolving industrial standards.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com