Description

Product Overview

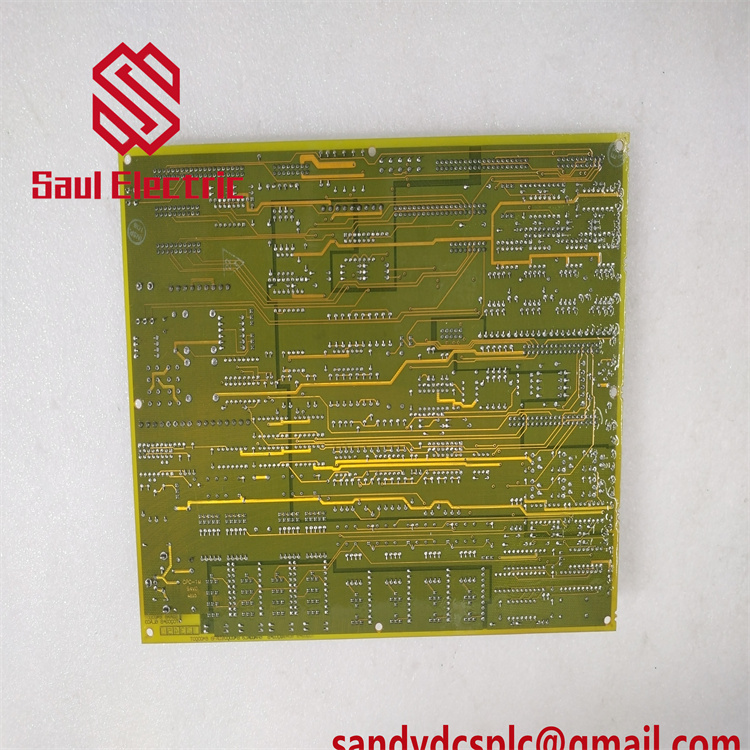

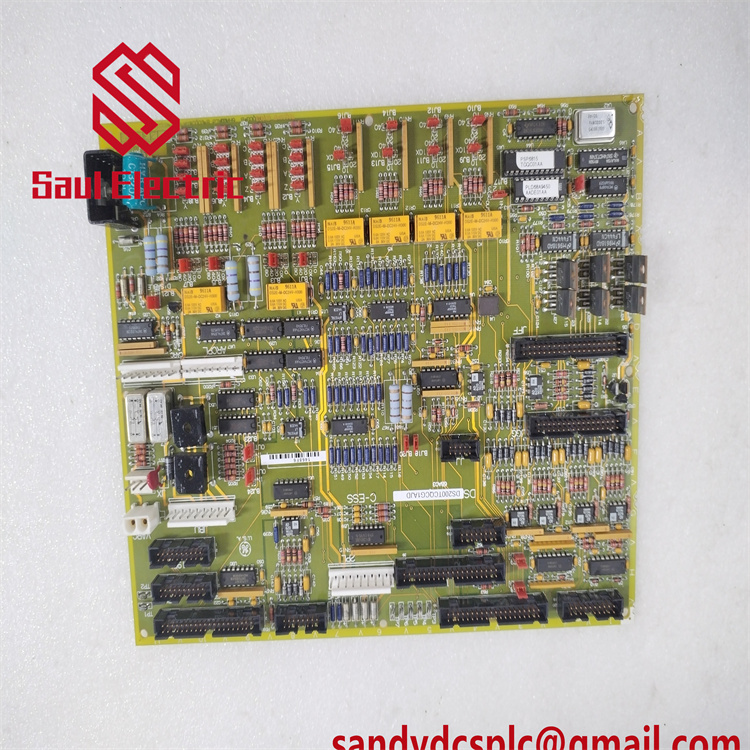

The GE DS200TCQAG1A is a high-performance Analog Input/Output (I/O) Board designed for GE’s Mark V Speedtronic Turbine Control System, a legacy platform widely used in gas and steam turbine automation. As a critical component of the Mark V series, this board serves as the interface between field sensors/actuators and the control system, enabling precise signal conditioning, scaling, and transmission for turbine speed, load, and temperature control.

The GE DS200TCQAG1A is a high-performance Analog Input/Output (I/O) Board designed for GE’s Mark V Speedtronic Turbine Control System, a legacy platform widely used in gas and steam turbine automation. As a critical component of the Mark V series, this board serves as the interface between field sensors/actuators and the control system, enabling precise signal conditioning, scaling, and transmission for turbine speed, load, and temperature control.

Engineered for industrial reliability, the GE DS200TCQAG1A supports a wide range of analog signals, including 4-20 mA currents, thermocouple inputs, and servo valve outputs . Its modular design allows seamless integration into distributed control architectures, ensuring compatibility with GE’s Mark V cabinets and terminal boards (e.g., TB QA and TB QC) . With advanced signal isolation and diagnostic capabilities, this board minimizes interference and downtime, making it ideal for mission-critical applications in power generation, oil and gas, and heavy industry.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | DS200TCQAG1A |

| Manufacturer | General Electric (GE) |

| Product Type | Analog I/O Board |

| Series | Mark V Speedtronic |

| Input/Output Range | 4-20 mA, thermocouples, LVDT, etc. |

| Channels | Multiple (varies by signal type) |

| Power Supply | 24 V DC (19.2-30 V DC) |

| Isolation | 2,500 V AC (channel-to-ground) |

| Connectors | 8 hardware connectors (e.g., JG, JF, JE) |

| Operating Temperature | -25°C to +60°C |

| Physical Dimensions | 330 mm (H) x 178 mm (W) x 100 mm (D) |

| Weight | 1.0 kg |

| Mounting | DIN rail (35 mm) |

| Diagnostics | LED indicators for status monitoring |

Main Features and Advantages

The GE DS200TCQAG1A excels in multi-signal processing, supporting a diverse range of analog inputs (e.g., vibration sensors, generator signals) and outputs (e.g., servo valve controls) . Its signal conditioning and scaling capabilities ensure accurate data conversion, even in high-interference environments, by incorporating noise filtering and cold junction compensation for thermocouple inputs .

The GE DS200TCQAG1A excels in multi-signal processing, supporting a diverse range of analog inputs (e.g., vibration sensors, generator signals) and outputs (e.g., servo valve controls) . Its signal conditioning and scaling capabilities ensure accurate data conversion, even in high-interference environments, by incorporating noise filtering and cold junction compensation for thermocouple inputs .

Designed for rugged industrial use, this board features robust PCB coating and EMC immunity, protecting against electromagnetic interference (EMI) and ensuring stable performance in harsh conditions . The hot-swap capability allows for maintenance without system shutdown, reducing downtime and enhancing operational efficiency. Additionally, its diagnostic LEDs provide real-time status feedback, enabling quick identification of faults such as sensor failures or communication errors .

Application Areas

The GE DS200TCQAG1A is primarily used in gas and steam turbine control systems, where it plays a vital role in regulating fuel flow, inlet guide vanes, and water/steam injection to optimize performance and reduce emissions . It is widely deployed in power generation plants for synchronizing turbines with the grid and monitoring critical parameters like voltage and current .

The GE DS200TCQAG1A is primarily used in gas and steam turbine control systems, where it plays a vital role in regulating fuel flow, inlet guide vanes, and water/steam injection to optimize performance and reduce emissions . It is widely deployed in power generation plants for synchronizing turbines with the grid and monitoring critical parameters like voltage and current .

In oil and gas facilities, this board supports applications such as compressor stall detection and fuel pressure regulation, ensuring safe and efficient operations . It also finds use in heavy industrial machinery, where it controls motor speed and processes temperature/pressure signals for quality assurance. By integrating with GE’s Mark V platform, the DS200TCQAG1A offers scalability and compatibility with legacy systems, making it a cost-effective solution for retrofitting or expanding automation infrastructure.

Related Products

- GE DS200TCQAG1B: A similar analog I/O board with additional jumper settings and LED indicators, suitable for applications requiring advanced signal customization .

- GE DS200TCQAG1BGE: A variant with enhanced thermal management, ideal for high-temperature environments .

- GE CI801 (3BSE022366R1): A Profibus DP interface module for connecting the DS200TCQAG1A to higher-level control systems .

- GE TU854 (3BSE069966R1): A termination unit that simplifies field wiring connections for the DS200TCQAG1A .

- GE DI880 (3BSE028586R1): A digital input module with SIL 3 certification for safety-critical applications .

Installation and Maintenance

Installation Preparation:

Before installing the GE DS200TCQAG1A, ensure the power supply is disconnected and the Mark V cabinet is grounded. Verify the DIN rail compatibility and secure the board using its screw holes . Use shielded cables for analog signals to minimize EMI and connect ribbon cables carefully to the terminal boards (e.g., TB QA) . Configure input ranges and communication settings using GE’s Speedtronic Mark V programming tools.

Installation Preparation:

Before installing the GE DS200TCQAG1A, ensure the power supply is disconnected and the Mark V cabinet is grounded. Verify the DIN rail compatibility and secure the board using its screw holes . Use shielded cables for analog signals to minimize EMI and connect ribbon cables carefully to the terminal boards (e.g., TB QA) . Configure input ranges and communication settings using GE’s Speedtronic Mark V programming tools.

Maintenance Recommendations:

Regularly inspect the board for loose connections or physical damage. Clean dust from the PCB using a static-free cloth and check LED indicators for 异常 status . Perform periodic calibration using certified signal sources to maintain measurement accuracy. For faulty boards, replace with compatible GE Mark V modules (e.g., DS200TCQAG1B) and ensure firmware updates are applied to maintain system compatibility .

Regularly inspect the board for loose connections or physical damage. Clean dust from the PCB using a static-free cloth and check LED indicators for 异常 status . Perform periodic calibration using certified signal sources to maintain measurement accuracy. For faulty boards, replace with compatible GE Mark V modules (e.g., DS200TCQAG1B) and ensure firmware updates are applied to maintain system compatibility .

Product Warranty

GE guarantees the DS200TCQAG1A against defects in materials and workmanship for 1 year from the date of purchase. This warranty covers repair or replacement of the board, provided it is used in accordance with GE’s specifications. GE’s global support network offers technical assistance, spare parts, and training to ensure optimal performance. For detailed terms, refer to GE’s official documentation or contact their customer service.

GE guarantees the DS200TCQAG1A against defects in materials and workmanship for 1 year from the date of purchase. This warranty covers repair or replacement of the board, provided it is used in accordance with GE’s specifications. GE’s global support network offers technical assistance, spare parts, and training to ensure optimal performance. For detailed terms, refer to GE’s official documentation or contact their customer service.

- HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com