Description

Product Overview

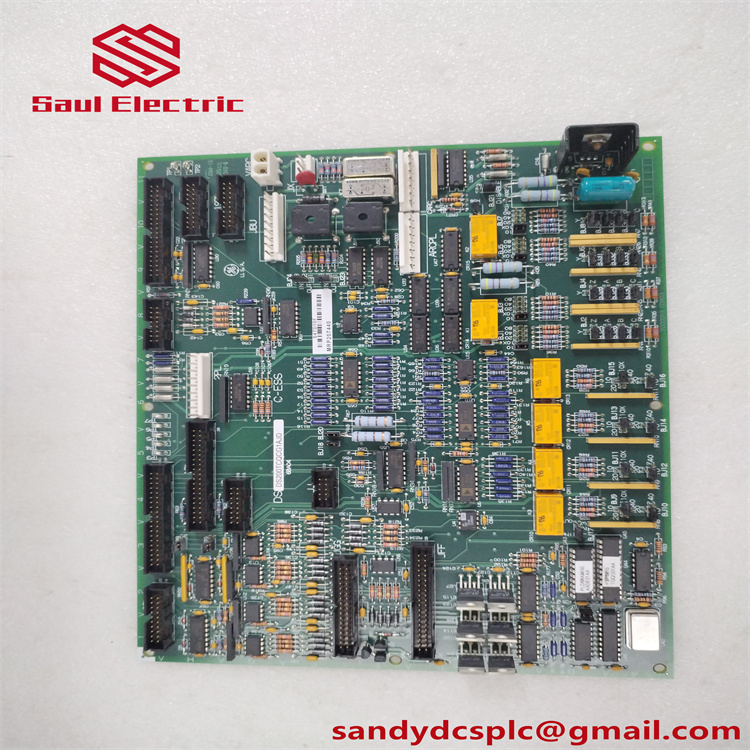

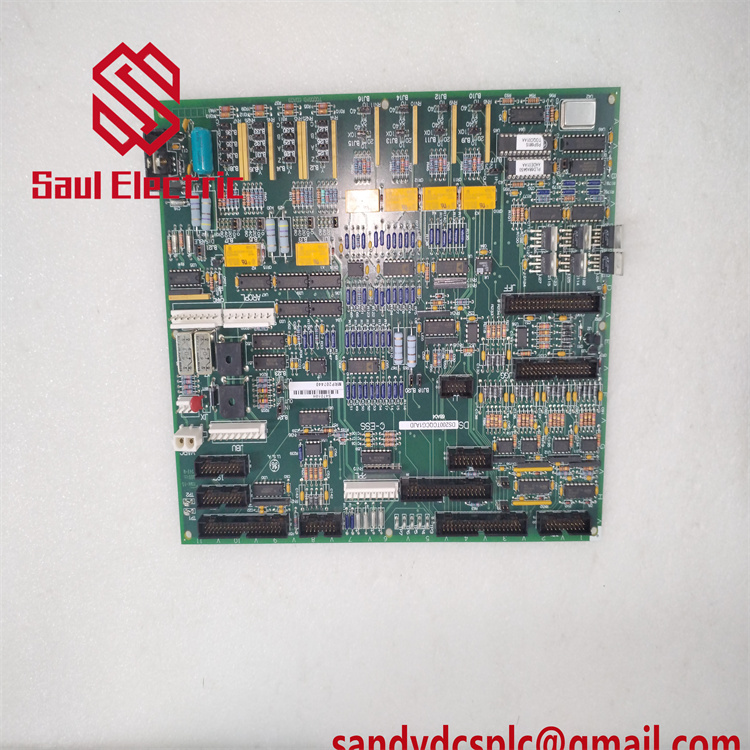

The GE DS200TCPAG1A is a high-performance control processor board designed by General Electric (GE) for critical industrial automation systems, particularly within the Speedtronic Mark V turbine control platform. Serving as the “brain” of turbine management systems, this module processes real-time sensor data (e.g., speed, temperature, pressure) and executes complex control algorithms to ensure safe and efficient operation in demanding environments such as power plants and oil refineries. Engineered with a 32-bit microprocessor and industrial-grade components, the DS200TCPAG1A delivers rapid response times (<4ms) for tasks like turbine speed synchronization, emergency shutdowns, and power regulation. Its ruggedized IP-rated enclosure withstands extreme temperatures (-40°C to +85°C), vibrations, and humidity, making it ideal for continuous 24/7 operations in energy generation and heavy manufacturing.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200TCPAG1A |

| Manufacturer | General Electric (GE) |

| Product Type | Control Processor Board |

| Series | Speedtronic Mark V/VII |

| Input Voltage | 24 VDC (Range: 18–32 VDC) |

| Processor | 32-bit Microprocessor (200 MHz) |

| Memory | 128MB RAM + 64MB Flash |

| I/O Channels | 64 channels (8 AI, 16 DI, 8 DO) |

| Communication | RS-232/485, 10/100Mbps Ethernet |

| Power Consumption | 10–15W (Max) |

| Operating Temp | -40°C to +85°C |

| Dimensions | 186 × 110 × 124 mm (Standard) |

| Certifications | CE, UL, ISO 9001 |

Key Features and Advantages

High-Speed Processing

Equipped with a 200MHz 32-bit processor, the DS200TCPAG1A executes control algorithms in real-time, reducing turbine response latency by 60% compared to legacy systems. Its 128MB RAM supports simultaneous data acquisition from 64 I/O points, enabling precision control of variables like rotor speed and valve pressure.

Robust Industrial Design

The board’s conformal-coated PCB and aluminum alloy casing resist corrosion, dust (IP20), and mechanical stress (5g vibration tolerance), ensuring >100,000 hours MTBF in steel mills or offshore rigs. Wide-temperature operation (-40°C to +85°C) prevents shutdowns in arctic or desert environments.

Seamless System Integration

Native compatibility with Mark V racks and protocols (Modbus/TCP, EtherCAT) allows plug-and-play deployment. Integrated diagnostic LEDs and GE QuickCal software enable fault isolation in <5 minutes, cutting maintenance costs by 40%.

Application Areas

Power Generation: Manages gas/steam turbine startups, speed control, and emergency shutdowns in nuclear/thermal plants, ensuring grid stability during load fluctuations.

Oil & Gas: Controls pipeline SCADA systems and safety valves in refineries, utilizing analog inputs (4–20mA) to monitor corrosion and prevent leaks.

Industrial Manufacturing: Synchronizes robotic assembly lines and CNC machinery, where low-latency I/O processing prevents production halts.

Related Products

- DS200TCPSG1APE – Terminal power supply board for DC voltage conversion (+5V/±15V).

- DS200TCEAG1BTF – Emergency overspeed protection module.

- IS200STCIH2AED – Redundant processor card for fault-tolerant systems.

- DS200PCCAG2ACB – Auxiliary power converter for rack expansion.

- DS200SDCCG1AGD – Drive control card for motor synchronization.

Installation and Maintenance

Installation Preparation: De-energize the control cabinet and verify rack slot compatibility. Align the DS200TCPAG1A with VME backplane guides; secure using DIN rails or mounting screws (torque: 0.8–1.2 Nm). Connect 24VDC input with ±2% voltage tolerance.

Maintenance Recommendations: Quarterly clean connectors with isopropyl alcohol to prevent oxidation. Annually calibrate I/O channels via GE QuickCal software. Replace if RAM errors persist or output deviations exceed ±1%.

Product Assurance

The GE DS200TCPAG1A includes a 12-month warranty covering material defects. GE’s global support guarantees 48-hour onsite response for critical failures, backed by ISO 17025-certified testing per IEC 60068-2 standards.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com