Description

Product Overview

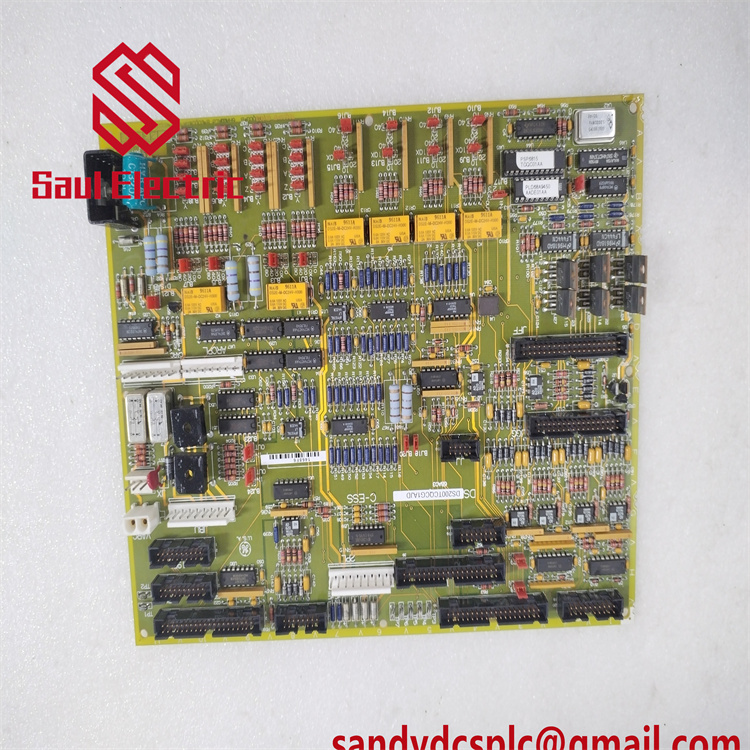

The GE DS200TCOAGIBDC is a Thermocouple Input/Output Module designed for GE’s Mark V Speedtronic Turbine Control System, a legacy platform widely used in gas and steam turbine automation. This board plays a critical role in conditioning thermocouple signals for temperature monitoring and control in turbine systems, ensuring precise operation and safety. It interfaces with thermocouple sensors (e.g., Type J, K, T) and provides cold-junction compensation to eliminate errors caused by ambient temperature fluctuations .

Engineered for rugged industrial environments, the DS200TCOAGIBDC features advanced signal conditioning circuitry and modular connectivity. Its design allows seamless integration into Mark V cabinets, ensuring compatibility with terminal boards (e.g., TB QA, TB QC) and other modules like the DS200TCQAG1BHF analog I/O board . With diagnostic LED indicators and field-replaceable components, this board supports real-time status monitoring and maintenance, making it ideal for power generation, oil and gas, and heavy industry applications.

Technical Specifications

| Parameter | Value |

| Product Model | DS200TCOAGIBDC |

| Manufacturer | General Electric (GE) |

| Product Type | Thermocouple Input/Output Module |

| Series | Mark V Speedtronic |

| Signal Type | Thermocouple (Type J, K, T) |

| Cold-Junction Compensation | Integrated (±0.5°C accuracy) |

| Connectors | 4 x 34-pin headers, 2 x 40-pin headers |

| Operating Temperature | -25°C to +60°C |

| Physical Dimensions | 330 mm (H) x 178 mm (W) x 100 mm (D) |

| Weight | 1.2 kg |

| Mounting | DIN rail (35 mm) |

| Protection | Overvoltage, overcurrent |

| Diagnostics | LED indicators for power and signal status |

Main Features and Advantages

- Thermocouple Signal Conditioning: Processes thermocouple inputs with high precision, ensuring accurate temperature measurements for turbine exhaust, bearing, and lubrication systems .

- Cold-Junction Compensation: Integrates a built-in temperature sensor to compensate for ambient temperature variations, maintaining measurement accuracy .

- Modular Design: Features 12 jumper switches for configurable signal routing, allowing customization for specific turbine configurations. The board also includes 6 LED indicators for real-time status monitoring .

- Rugged Reliability: Incorporates EMI/RFI shielding and PCB coating to withstand harsh industrial environments. Heat sinks and overload protection mechanisms minimize downtime .

- Easy Integration: Plug-and-play design with no software configuration required. Hot-swap capability enables maintenance without system shutdown .

Application Areas

- Power Generation: Supports temperature monitoring for turbine exhaust, bearing systems, and lubrication oil in gas/steam turbine plants.

- Oil and Gas: Ensures reliable signal conditioning for compressor temperature control and distributed control architectures.

- Heavy Industry: Powers motor drives and process control modules in machinery requiring high-precision temperature monitoring, such as steel mills and chemical plants.

Related Products

- GE DS200TCQAG1BHF: An analog I/O board that interfaces with the DS200TCOAGIBDCto scale and condition thermocouple signals .

- GE DS200TCPDG1BCC: A power distribution board providing 125 V DC input to support I/O modules like the DS200TCOAGIBDC.

- GE TU854 (3BSE069966R1): A termination unit that simplifies field wiring connections for thermocouple signals .

Installation and Maintenance

- Installation: Secure the board on a 35 mm DIN rail, connect thermocouple inputs via the 34-pin headers, and route output signals through the dedicated connectors. Use shielded cables to minimize EMI .

- Maintenance: Regularly inspect for loose connections, clean dust from the PCB, and test signal integrity. Replace faulty components (e.g., resistors, capacitors) as needed. Firmware updates should be applied as part of routine maintenance .

Product Warranty

GE guarantees the DS200TCOAGIBDC against defects in materials and workmanship for 1 year from the date of purchase. This warranty covers repair or replacement, provided the board is used in accordance with GE’s specifications. Third-party suppliers like AxControl may offer extended warranties (e.g., 3 years) for refurbished units .

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com